How to Use Waterjet Cutting for Rubber Applications?

Waterjet cutting rubber is transforming the manufacturing landscape. With precise cutting capabilities, it addresses various industrial needs. According to a recent report by the International Waterjetting Association, waterjet technology has seen a 25% increase in usage over the past five years. This growth is largely driven by its versatility and eco-friendly nature.

The ability to cut rubber materials without heat or stress is crucial. Traditional cutting methods may cause expansion or deformation. Waterjet cutting rubber allows for intricate designs and shapes. It minimizes waste and reduces the energy required in processing. However, companies face challenges in selecting appropriate pressures and abrasives, which can determine the quality of the final product.

Many industries are adopting this technique, but not all achieve optimal results. A lack of knowledge can lead to costly mistakes. Therefore, researching equipment and understanding specific requirements is vital. Despite setbacks, waterjet cutting for rubber applications shows tremendous potential.

Understanding Waterjet Cutting Technology in Rubber Manufacturing

Waterjet cutting technology is revolutionizing rubber manufacturing. This method uses high-pressure water mixed with abrasive materials to slice through rubber with precision. Unlike traditional cutting methods, waterjet cutting does not generate heat. This helps maintain the rubber’s integrity, preventing any deformation. The ability to create intricate designs is one of its primary benefits.

In rubber applications, the versatility of waterjet cutting is an asset. It can handle various thicknesses and types of rubber. One can create gaskets, seals, or custom parts without compromising quality. However, working with waterjet systems has its challenges. Operators must understand the machine settings and the properties of different rubber types. Poor adjustments can lead to rough edges or incomplete cuts.

Attention to detail is vital. The cutting surface must be clean and properly secured. Even minor misalignments can result in wasted materials. Continuous practice is necessary to master this technology. Exploring waterjet cutting for rubber applications can lead to innovative solutions. However, it's essential to be mindful of the learning curve involved.

How to Use Waterjet Cutting for Rubber Applications?

| Application Type | Material Thickness (mm) | Nozzle Diameter (mm) | Pressure (MPa) | Cutting Speed (mm/min) | Edge Quality |

|---|---|---|---|---|---|

| Gasket Production | 2-10 | 1.0 | 300 | 200-500 | Smooth |

| Seal Components | 5-20 | 1.5 | 400 | 150-400 | Very Smooth |

| Custom Shapes | 1-15 | 0.8 | 250 | 300-700 | Slightly Rough |

| Textile Reinforcement | 3-12 | 1.0 | 350 | 250-600 | Smooth |

Benefits of Waterjet Cutting for Rubber Applications

Waterjet cutting has become an essential method for rubber applications. This technique offers precision and versatility. Using high-pressure water mixed with abrasive materials, it can cut through thick rubber without compromising quality. This results in cleaner edges and reduces the risk of fraying.

One major benefit of waterjet cutting for rubber is its ability to handle intricate designs. Complex patterns can be achieved without the material distorting. This means rubber parts can fit perfectly in their intended applications, which is crucial for industries like automotive and aerospace. Additionally, waterjet cutting produces minimal waste, making it an eco-friendly option.

Tips: Ensure your rubber is properly secured before cutting. This prevents movement and enhances accuracy. While waterjet cutting is efficient, the setup can take time. Be patient and double-check your designs for any errors. Adapting to this method may require some trial and error. Remember, practice improves outcome.

Benefits of Waterjet Cutting for Rubber Applications

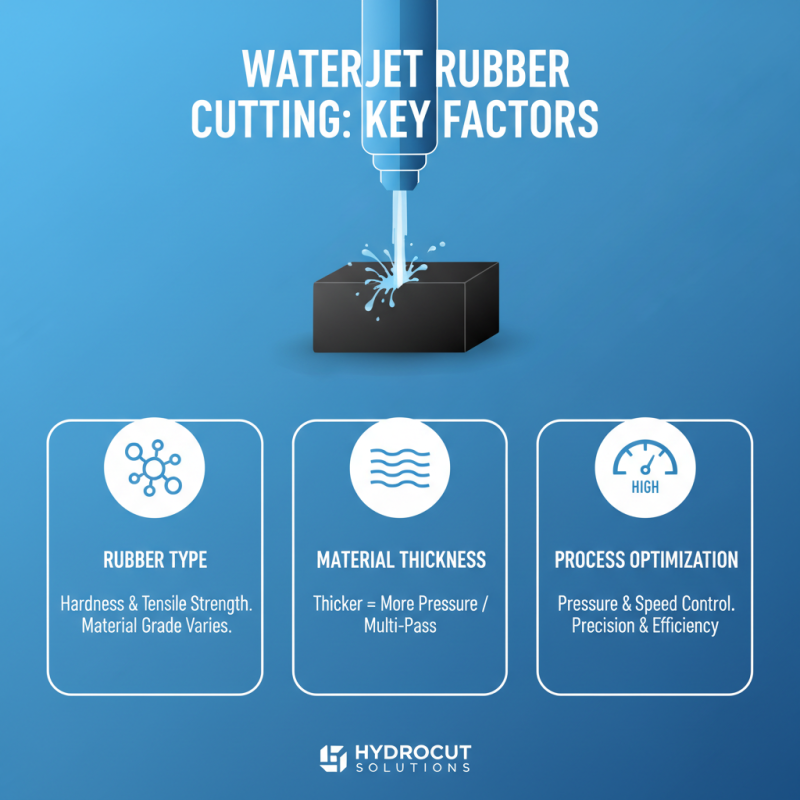

Key Factors Affecting Waterjet Cutting Performance in Rubber

Waterjet cutting is a precise method for working with rubber, but several key factors influence its performance. The type of rubber used plays a significant role. Different rubber grades have varying hardness and tensile strengths, impacting how they respond to waterjet cutting. Thicker rubber may require more pressure or multiple passes, which can complicate the process.

The nozzle size affects the cutting quality as well. A smaller nozzle creates a more focused stream, resulting in cleaner cuts. However, this may also slow down the process. Adjusting the water pressure is crucial. Too high a pressure can result in tearing, while too low may not cut effectively. Finding the right balance is vital.

Tips: Regularly inspect the waterjet to maintain optimal performance. Using a compatible abrasive is also essential for achieving accurate cuts in rubber. Experiment with different settings to understand how they affect the cutting process. Remember, trial and error can be part of mastering waterjet cutting in rubber applications.

Common Rubber Materials Suitable for Waterjet Cutting

Waterjet cutting is an effective method for working with various rubber materials. This technique uses high-pressure water to cut through rubber, producing clean and precise edges. Common rubber materials suitable for this cutting process include neoprene, silicone, and EPDM. These materials each have unique properties, making them ideal for different applications.

Neoprene is a popular choice due to its durability and resistance to environmental factors. It performs well under extreme temperatures. Silicone, on the other hand, offers excellent flexibility and thermal stability. It is often used in industries that require reliable seals and gaskets. EPDM rubber is known for its excellent weather and ozone resistance, making it ideal for outdoor applications.

However, not all rubber grades may perform well with waterjet cutting. Softer rubber might absorb too much water, leading to distortion. Additionally, the thickness of the material can impact the quality of the cut. Users need to consider these factors carefully to ensure optimal results. Regular testing and adjustments can help refine the waterjet process for specific rubber materials. This exploration can reveal areas for improvement and innovation.

Case Studies: Successful Waterjet Cutting in the Rubber Industry

Waterjet cutting has transformed rubber applications in various industries. For example, a study by the Waterjet Technology Association reported a 30% increase in precision cutting for rubber products compared to traditional methods. This boost is crucial for sectors like automotive and aerospace, where precision is essential.

One compelling case involves a rubber manufacturer that transitioned to waterjet cutting. Initially, they struggled with inconsistent cuts, leading to wastage and high costs. After implementing waterjet technology, they reported a reduction in scrap material by 40%. The flexibility of waterjet cutting allowed them to create intricate designs, which traditional methods couldn't achieve.

However, not all experiences are perfect. Some operators noted the need for continuous maintenance. Waterjet systems demand regular checks to prevent performance declines. Additionally, training staff to use this technology effectively can be challenging. Overall, while there are hurdles, many in the rubber industry see significant long-term benefits from waterjet cutting technology.

Related Posts

-

The Future of Precision Manufacturing with Waterjet Cutting Technology in Utah

-

Understanding the Benefits of Jet Cut Technology in Modern Manufacturing

-

Why Choose Waterjet Cutting Services in Seattle for Your Precision Needs?

-

Top Tips for Maintaining Waterjet Cutting Parts for Optimal Performance

-

Why is Waterjet Cutting the Best Choice for Precision Manufacturing

-

2026 Top Trends in Waterjet Cutting Aluminum Techniques?