Why is Waterjet Cutting the Best Choice for Precision Manufacturing

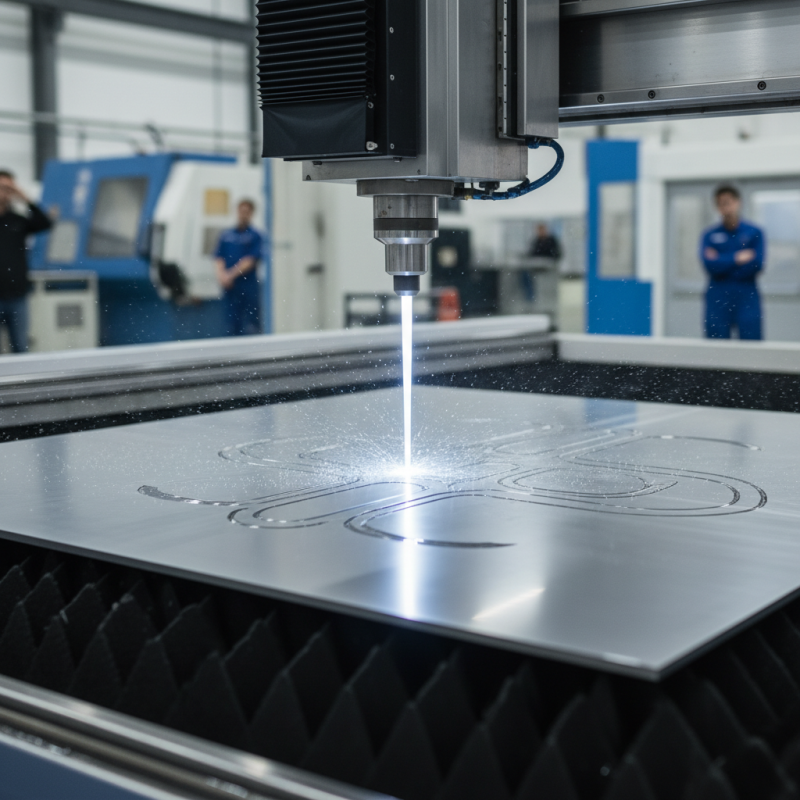

Waterjet cutting has emerged as a leading technology in precision manufacturing. It offers unmatched accuracy and versatility, making it essential in various industries. According to a report from MarketsandMarkets, the global waterjet cutting market is projected to reach $1.2 billion by 2025, driven by the demand for high-quality and efficient cutting processes.

Industry expert Dr. Emily Carter states, "Waterjet cutting is the future of precision fabrication, enabling intricate designs without compromising material integrity." This sentiment resonates widely in manufacturing sectors where precision is paramount. Waterjet cutting uses high-pressure water to slice through materials, minimizing thermal distortion. It can cut metal, stone, glass, and more, with edge quality that often surpasses conventional methods.

However, not all applications are suited for waterjet cutting. Some materials may pose challenges, requiring careful consideration of parameters. The technology, while advanced, still faces limitations in certain thicknesses and material types. As industries evolve, understanding these nuances is essential for leveraging waterjet cutting effectively. Being informed can lead to better decisions in manufacturing processes.

Benefits of Waterjet Cutting in Precision Manufacturing

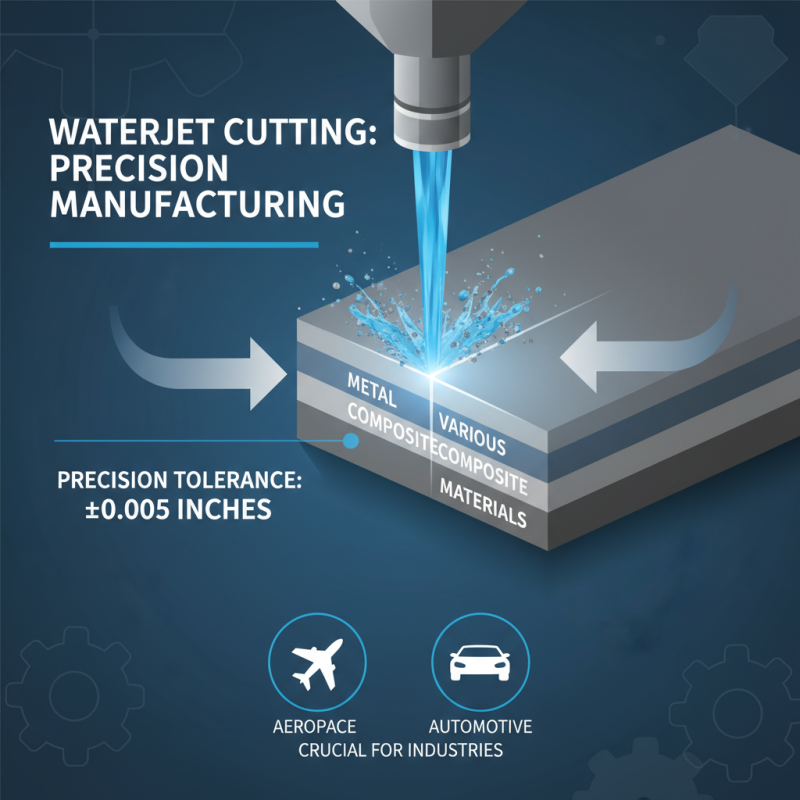

Waterjet cutting stands out as a premier method for precision manufacturing. This technique uses high-pressure water mixed with abrasives to cut through various materials efficiently. Reports show that waterjet cutting can achieve tolerances as tight as ±0.005 inches. This precision is crucial for industries like aerospace and automotive, where every detail matters.

One of the significant benefits is the ability to cut complex shapes without the need for extensive tooling. This adaptability can reduce lead times by up to 75%, translating to faster project completions. Additionally, the process generates minimal heat, which means materials maintain their structural integrity. However, some users note that the setup time can be longer compared to other methods. This inconsistency can be a drawback in fast-paced environments.

Moreover, waterjet cutting is versatile. It can work on metals, ceramics, glass, and even composites. The ability to use a single setup for multiple materials is invaluable. According to industry studies, around 80% of manufacturers see a noticeable decrease in waste. This is a critical factor for those striving for sustainable practices. Nevertheless, the initial cost of waterjet machines can be a sticking point for smaller operations. Balancing cost with efficiency remains a challenge.

How Waterjet Technology Achieves High Precision and Accuracy

Waterjet cutting stands out in precision manufacturing. It utilizes high-pressure water mixed with abrasive materials to cut through various materials. This method offers unparalleled accuracy and minimizes the risk of thermal distortion.

Achieving high precision and accuracy is critical in manufacturing. Waterjet technology allows for tight tolerances. It can cut intricate designs without compromising the integrity of the material. This is particularly beneficial for delicate materials like glass or metals. Operators can achieve clean edges and complex shapes without further machining.

**Tip:** Regular maintenance of the waterjet system is essential for accuracy. Worn components can lead to imprecision in cuts, affecting overall quality.

Nevertheless, it’s essential to be aware of limitations. For instance, waterjet cutting might not be ideal for very thick materials. Some users report challenges with speed compared to laser cutting in certain applications.

**Tip:** Evaluate your materials and desired thickness before choosing waterjet cutting. Understanding your specific needs can lead to better outcomes.

Versatility of Waterjet Cutting in Diverse Material Applications

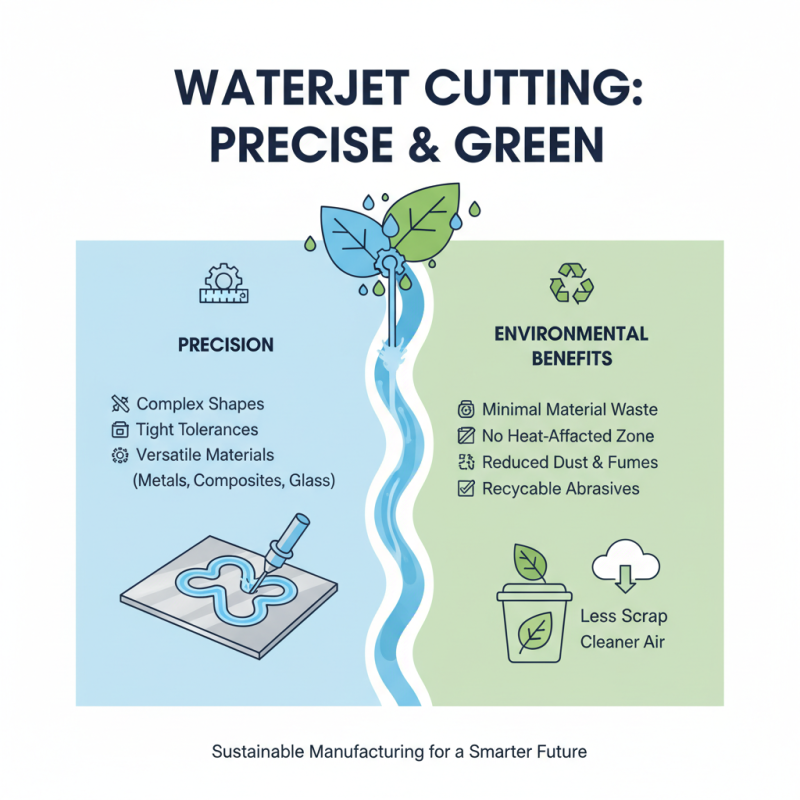

Waterjet cutting stands out for its versatility in various material applications. This technology effectively processes materials like metals, glass, stone, and plastics. In fact, a recent industry report indicates that waterjet cutting can reduce material waste by up to 20%. This capability not only saves costs but also enhances sustainability practices in manufacturing.

The precision offered by waterjet cutting is remarkable. It can achieve tolerances of ±0.005 inches, making it ideal for intricate projects. However, while waterjet cutting excels at thick materials, it may struggle with very thick metal, requiring multiple passes, which can extend production time unexpectedly. For many, this is a point of concern.

Moreover, waterjet cutting accommodates complex designs without requiring extensive setup changes. The process can easily transition from one job to another without significant downtime. However, the technology does require skilled operators for optimal results, which can be a challenge. Some manufacturers may face a learning curve in effectively utilizing this machinery, impacting productivity during the adjustment period.

Cost-Effectiveness of Waterjet Cutting for Manufacturers

Waterjet cutting has gained popularity due to its cost-effectiveness in precision manufacturing. This method uses high-pressure water to cut materials, reducing waste significantly. Manufacturers often face high material costs and tight budgets. Waterjet cutting minimizes excess scrap. This makes it a financially wise choice.

Complex projects may lead to unexpected expenses. Traditional methods can rack up costs quickly. Waterjet cutting offers an efficient alternative. It can handle thick materials and intricate designs without expensive tooling changes. This flexibility saves time, allowing for rapid prototyping and faster production cycles.

However, not all projects are suited for waterjet cutting. Certain materials may not yield the best results. Manufacturers should evaluate their specific needs before committing. Balancing cost with quality is crucial. Understanding the capabilities and limitations of this technique helps avoid costly mistakes.

Cost-Effectiveness of Waterjet Cutting for Manufacturers

Environmental Considerations in Waterjet Cutting Process

Waterjet cutting stands out not only for its precision but also for its environmental benefits. This technology uses high-pressure water mixed with abrasives to cut materials. The process generates minimal waste. This is a significant advantage for manufacturers looking to reduce their footprint.

The water used in the cutting process can often be recycled. This helps conserve resources and lowers operational costs. Manufacturers should be mindful of how they handle wastewater. Proper filtration systems can clean water for reuse. This is an area where many still need improvement.

Tips: Always check local regulations regarding water disposal. Implementing best practices for water management is essential. Training staff on sustainable practices is equally important. These efforts ensure minimal environmental impact while enhancing production efficiency. Remember, small changes can lead to significant gains in sustainability.

Related Posts

-

Why Choose Waterjet Cutting Services in Seattle for Your Precision Needs?

-

Top Tips for Maintaining Waterjet Cutting Parts for Optimal Performance

-

The Future of Precision Manufacturing with Waterjet Cutting Technology in Utah

-

Understanding the Benefits of Jet Cut Technology in Modern Manufacturing

-

Top 10 Waterjet Cutting Parts for Precision Engineering Applications

-

Top Benefits of Waterjet Cutting for Your Manufacturing Needs