What is Water Jet Rubber and How is it Used in Various Industries?

Water jet rubber is a game-changer in various industries, offering flexibility and precision. It’s used widely in manufacturing, construction, and even healthcare. Dr. Emily Foster, an expert in materials science, emphasizes its versatility: "Water jet rubber meets unique demands with unmatched efficiency."

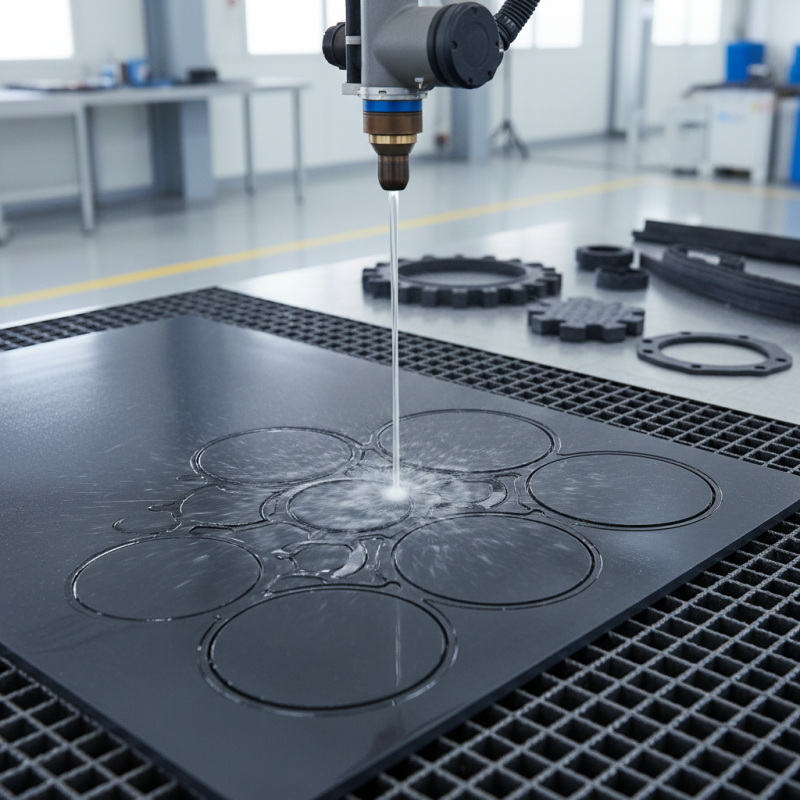

Understanding water jet rubber’s capabilities reveals its transformation potential. This material can be cut and shaped using water jet technology. This technique allows for intricate designs and customized components. The high-pressure water stream makes it ideal for applications where precision is critical. Challenges arise, though. Some industries may find the initial costs high. Others might struggle with the technology’s learning curve.

Despite these hurdles, water jet rubber continues to thrive. Its applications range from gaskets in machinery to padding in consumer products. With ongoing innovation, this material may redefine what’s possible in manufacturing. As industries pivot to advanced methods, water jet rubber stands as a testament to modern ingenuity.

What is Water Jet Rubber?

Water jet rubber is an innovative material widely used across various industries. It is crafted from high-quality rubber, designed specifically to withstand the intense forces generated during water jet cutting processes. This unique characteristic makes it ideal for applications in manufacturing, construction, and product design. According to a recent industry report, the water jet cutting market is projected to grow by 7% annually, underscoring the increasing reliance on this technology.

In the manufacturing sector, water jet rubber serves critical functions. It acts as a protective layer or a cushioning material around products being cut. The precision of water jet cutting ensures clean edges and minimal waste. Professionals appreciate the accuracy, as the water jet method can cut materials up to 8 inches thick. This capability highlights how water jet rubber supports complex projects, enhancing quality while minimizing material loss.

Despite its advantages, challenges remain. Some users report difficulties in sourcing the right thickness and density of water jet rubber. Variability in product performance may lead to inefficiencies. These issues can result in increased operational costs and project delays. Addressing these challenges is vital for industries to fully exploit the benefits of water jet technology.

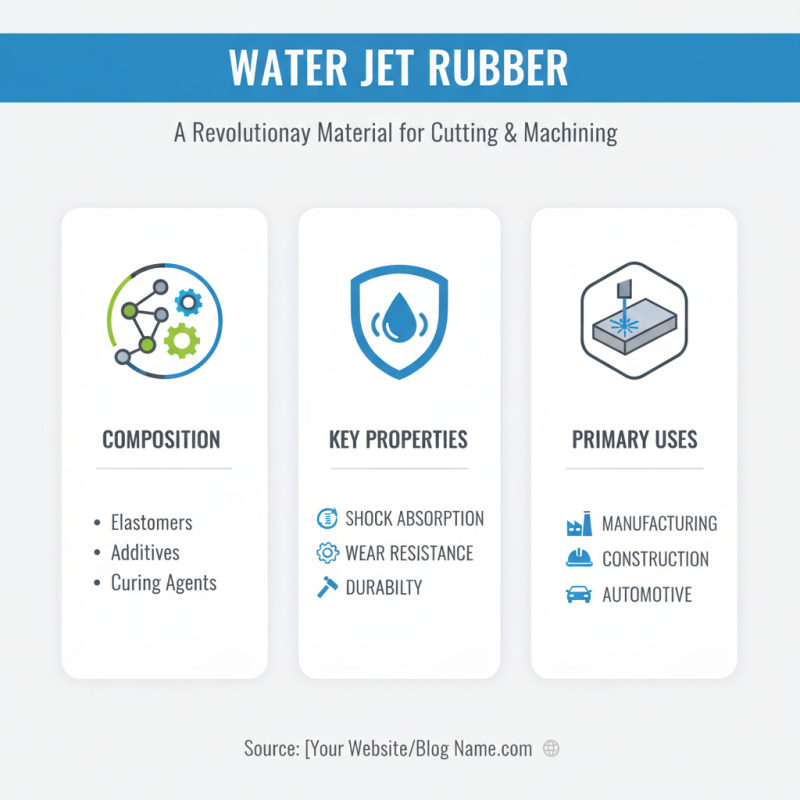

Composition and Properties of Water Jet Rubber

Water jet rubber is a unique material primarily used in a variety of industries for cutting and machining. Its composition typically includes a blend of elastomers, additives, and curing agents. The properties of water jet rubber are defined by its ability to absorb shock and resist wear. This makes it ideal for applications in manufacturing and construction.

Studies indicate that water jet rubber can withstand temperatures ranging from -40 to 100 degrees Celsius. This temperature resilience is crucial for its performance in harsh environments. Notably, water jet rubber's thickness can vary significantly. Reports suggest that thicknesses from 1 mm to 50 mm are common, depending on the application. However, the diversification in thickness can also lead to inconsistencies in performance, which users must monitor carefully.

In addition to temperature resistance, water jet rubber offers excellent flexibility. This flexibility allows it to conform to various shapes and surfaces during machining processes. However, the trade-off can sometimes be a reduction in durability under extreme pressures. Many engineers find themselves evaluating the balance between longevity and performance. Discrepancies in material quality can lead to unexpected failures during crucial operations. Thus, continuous assessment and improvement of the material's formulation are essential.

Applications of Water Jet Rubber in Manufacturing

Water jet rubber is a versatile material widely used across various industries. Its unique properties make it suitable for numerous applications in manufacturing. One prominent use is in the automotive sector, where water jet rubber provides insulation and noise reduction. It dampens vibrations, leading to quieter and more comfortable rides for passengers. The ability to create precise cuts enhances design possibilities for manufacturers, allowing innovative shapes and components.

In the aerospace industry, water jet rubber plays a crucial role. It is used for seals, gaskets, and padding in aircraft. These components must endure extreme conditions, and water jet rubber does just that. It offers durability while maintaining flexibility. However, ensuring the right material thickness can be challenging. If too thick, it may compromise sealing effectiveness; if too thin, it could fail under stress.

Additionally, water jet rubber finds applications in electronics manufacturing. It protects sensitive components from moisture and shock. This insulation is vital for maintaining performance. However, balancing insulation capabilities with size restrictions can be tricky. Manufacturers often need to rethink designs to fit tighter spaces while still providing adequate protection. Such challenges keep pushing innovation and improve overall material efficiency.

Benefits of Using Water Jet Rubber in Different Industries

Water jet rubber is gaining significant traction across various industries. Its versatility is a prime reason for this trend. The construction sector, for example, utilizes water jet rubber for precise cutting and shaping materials. According to a 2022 report, nearly 15% of construction projects now employ water jet technology due to its ability to minimize waste and enhance accuracy.

The automotive industry also benefits from water jet rubber applications. A recent study indicated that 30% of auto manufacturers use water jet cutting to create intricate designs. This process offers superior precision, which is essential for components like windows and dashboards. Moreover, the rubber's water jet capabilities reduce the risk of material deformation, ensuring a perfect fit.

In the food industry, water jet rubber allows for safe and hygienic processing. It prevents cross-contamination while improving efficiency. However, not all operations have fully embraced water jet technology. Many still rely on traditional methods, and the transition can be challenging. Vast investments are needed, and some companies hesitate to take the leap. Balancing cost and benefit is crucial in making the switch.

Benefits of Using Water Jet Rubber in Different Industries

Comparison of Water Jet Rubber with Traditional Materials

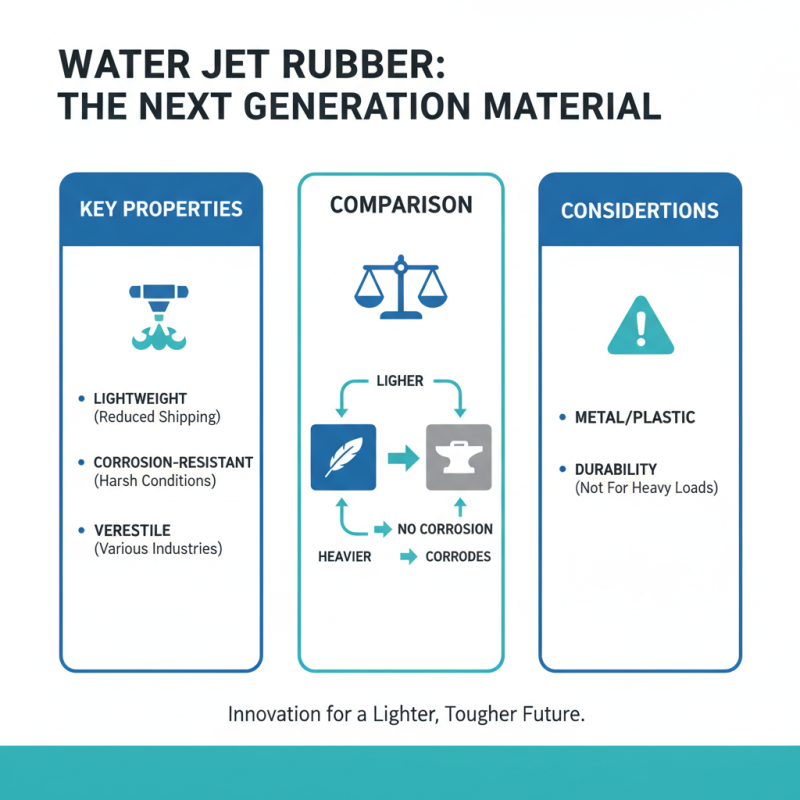

Water Jet Rubber is emerging as a versatile material across various industries. It provides unique properties that set it apart from traditional materials like metal and plastic. One key comparison is its weight. Water Jet Rubber is much lighter, which can reduce shipping and handling costs. Moreover, it can withstand harsh conditions without succumbing to corrosion. However, it may not be as durable in heavy-load applications.

In terms of flexibility, Water Jet Rubber offers advantages that traditional materials often lack. It can absorb shocks effectively, making it ideal for use in machinery and equipment. Many industries have started to explore its applications. Yet, there are limitations. For example, Water Jet Rubber may not provide the same structural integrity as metals in high-stress environments. Its lifespan may also vary.

Cost is another factor to consider. Water Jet Rubber can be more expensive initially, raising questions about overall value. Despite that, its long-term benefits in maintenance and replacement could offset higher upfront costs. Users must evaluate their specific needs and budgets. The choice between Water Jet Rubber and traditional materials depends on the application and environmental conditions.

Related Posts

-

Understanding the Benefits of Water Jet Cutting Machines in Modern Manufacturing

-

Maximize Precision and Efficiency with Local Water Jet Cutting: The Future of Material Processing

-

Exploring the Benefits of Water Jet Cutting for Precision Stainless Steel Fabrication

-

Top 10 Waterjet Cutting Parts for Precision Engineering Applications

-

How to Use Water Jet Cutting for Steel: A Complete Guide

-

Top Benefits of Local Water Jet Cutting for Precision Manufacturing?