How to Use Water Jet Cutting for Steel: A Complete Guide

Water jet cutting steel has emerged as a revolutionary technique in the manufacturing industry, combining precision and versatility. This cutting method utilizes high-pressure water, often mixed with abrasive materials, to slice through steel with remarkable accuracy and minimal thermal distortion. According to a report by the International Waterjet Technology Association, the demand for water jet cutting technology in the steel sector has grown by over 20% annually in recent years, driven by its ability to produce intricate designs and reduce material waste efficiently.

Expert in the field, Dr. Emily Carter, a leading researcher at the Advanced Manufacturing Institute, emphasizes the significance of this cutting method: "Water jet cutting steel is not just about precision; it's about creating sustainable manufacturing practices that adapt to the needs of modern industry." This technique offers benefits such as the capability to cut a wide range of materials and thicknesses without compromising quality, positioning it as a cornerstone in contemporary manufacturing processes. As businesses seek more efficient and environmentally-friendly methods, understanding how to effectively use water jet cutting for steel becomes increasingly essential.

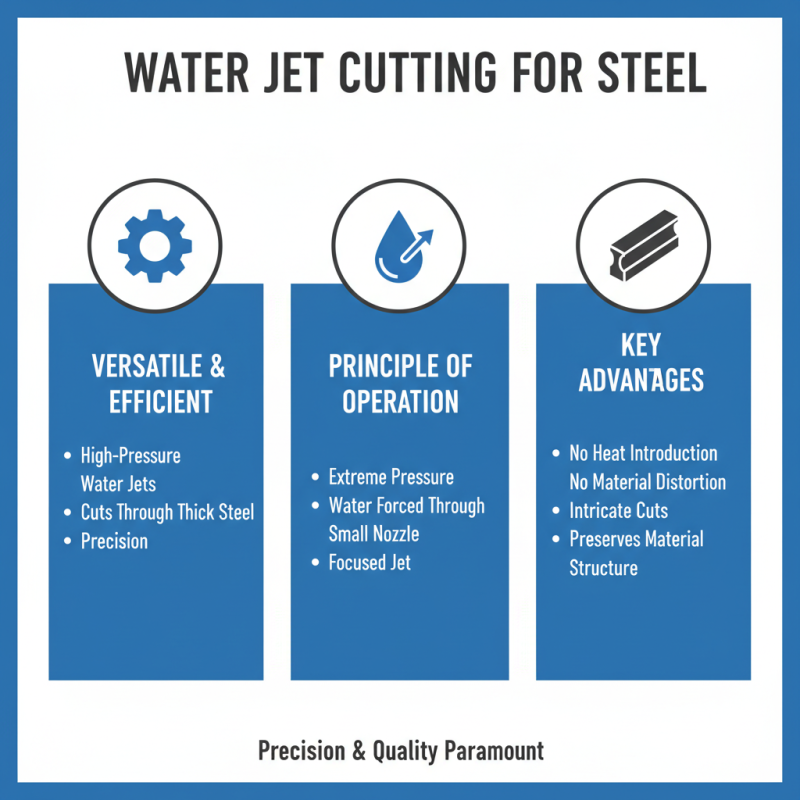

Understanding Water Jet Cutting: Principles and Advantages for Steel

Water jet cutting is a versatile and efficient method for processing steel, utilizing high-pressure water jets to cut through material with precision. This technology operates on the principle of extreme pressure, where water is forced through a small nozzle, resulting in an incredibly focused jet that can easily penetrate even the thickest steel. The key advantage of using water jet cutting for steel is its ability to create intricate cuts without introducing heat, which means there’s no distortion or alteration to the material’s structure. This makes it a perfect choice for applications where precision and quality are paramount.

When utilizing water jet cutting for steel, there are several tips to consider for optimal results. First, ensure the material is properly secured to prevent any movement that could compromise cut accuracy. Additionally, selecting the right nozzle size and water pressure is crucial to achieving the desired cut speed and quality. Higher pressures often yield faster cuts, but it’s important to balance speed with the material's integrity and finish.

Another advantage of water jet cutting is its versatility; it can handle various thicknesses of steel and create complex shapes without the need for extensive tooling. By taking advantage of this method, industries can minimize material waste and reduce production times while maintaining a high standard of quality in their steel components. Understanding these principles and advantages allows manufacturers to choose water jet cutting confidently for their steel processing needs.

Key Components of Water Jet Cutting Systems and Their Functions

Water jet cutting is a versatile and precise method for machining various materials, particularly steel. The effectiveness of this cutting technique relies heavily on several key components that work together to deliver high-quality results.

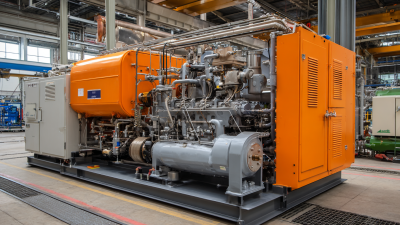

One of the fundamental components of a water jet cutting system is the pump. This device pressurizes water to extremely high levels, usually between 30,000 to 90,000 psi, enabling it to effectively penetrate tough materials. The pressurized water is then directed through a cutting head, which includes an orifice and a mixing chamber. The orifice, a small opening, controls the flow of water, while the mixing chamber introduces an abrasive material, typically garnet, which enhances the cutting ability of the water jet. Together, these elements create a powerful cutting stream capable of producing intricate shapes and fine details.

Additionally, the control system is vital for the precise operation of the water jet cutter. This system is responsible for directing the cutting head along programmed paths, ensuring accuracy in both position and movement. Advanced software allows operators to easily design parts and adjust settings according to material type and thickness, thus optimizing the cutting process. The combination of these components—pump, cutting head, and control system—forms the backbone of an efficient water jet cutting system, enabling it to tackle a variety of steel cutting applications with finesse and efficiency.

How to Use Water Jet Cutting for Steel: A Complete Guide

| Component | Function | Material | Typical Pressure (psi) |

|---|---|---|---|

| Pump | Generates high-pressure water | Stainless Steel | 60,000 |

| Abrasive Garnet | Cuts through steel | Garnet | N/A |

| Cutting Head | Mixes water and abrasive, directs jet | Ceramic | N/A |

| Control System | Coordinates cutting path | Electronics | N/A |

| Worktable | Supports and holds the material in place | Steel | N/A |

Process Parameters: Pressure, Abrasive Flow Rate, and Cutting Speed in Steel

When using water jet cutting for steel, understanding the key process parameters—pressure, abrasive flow rate, and cutting speed—is crucial for achieving the desired results. The pressure applied during the cutting process is typically measured in pounds per square inch (PSI). Higher pressures lead to increased cutting ability and precision, as they produce a more focused jet. For steel, pressures often range from 30,000 to 90,000 PSI, depending on the thickness of the material being cut. It is essential to find the right balance; too high a pressure can cause unnecessary wear on the nozzle and affect the quality of the cut.

Abrasive flow rate is another vital parameter that can significantly impact cutting efficiency. This refers to the quantity of abrasive material being mixed with the water jet stream. Adjusting the abrasive flow rate enables operators to control the cutting depth and surface finish. Generally, a higher flow rate results in a faster cut but may also lead to a rougher surface finish. Operators should start with a moderate abrasive flow rate and adjust based on the specific requirements of the project.

Tips: When setting up a water jet cutting job, always run a few test cuts with different pressure and flow rate combinations. This allows you to fine-tune your parameters for the best performance. Additionally, maintaining a consistent cutting speed throughout the process is essential; varying speeds can lead to uneven cuts. Opt for a steady pace while keeping an eye on material feedback for optimal results.

Applications of Water Jet Cutting in Steel Fabrication and Manufacturing

Water jet cutting has become a vital method in steel fabrication and manufacturing due to its versatility and precision. It utilizes a high-pressure stream of water, sometimes mixed with abrasives, to slice through various thicknesses of steel with minimal heat-affected zones. This technique is particularly beneficial in industries where intricate designs and high tolerances are necessary. It allows for complex cuts—such as curves, contours, and even detailed engravings—without compromising the integrity of the material.

Applications of water jet cutting in steel manufacturing span across numerous sectors, including automotive, aerospace, and architectural design. In the automotive industry, it is used for cutting intricate components and panels, while in the aerospace sector, it handles the cutting of lightweight yet durable steel parts for improved performance. Additionally, in architectural design, water jet cutting allows for innovative metal pattern designs that enhance aesthetic appeal without sacrificing strength. Its ability to work on a range of steel alloys makes it an indispensable tool for fabricators looking to innovate and elevate their production capabilities.

Applications of Water Jet Cutting in Steel Fabrication

Safety Considerations and Maintenance Best Practices for Water Jet Systems

When working with water jet cutting systems, safety should always be a top priority. Proper personal protective equipment (PPE) such as

safety goggles, gloves, and ear protection is essential, as the cutting process can generate high pressure and noise.

Additionally, ensure that the work area is clear of unnecessary personnel and maintain a safe distance from the cutting head to prevent accidental injuries.

Regular safety training sessions for all operators can further enhance safety awareness and preparedness.

Maintaining water jet systems is crucial for ensuring optimal performance and longevity.

Regular checks of the abrasive water jet nozzle for wear and replacement are essential to maintain cutting efficiency.

It’s also important to flush the system periodically to prevent blockages from residual materials. Properly calibrating the pressures and ensuring alignment can reduce the risk of system malfunctions.

Tips: Always keep a maintenance log to track servicing and inspections. This can help you identify patterns or recurring issues

before they become larger problems. Moreover, clean the water filtration system regularly to prevent contaminants from affecting the cutting quality.

Finally, create a routine checklist that operators can follow before starting the machine to ensure all safety and maintenance measures are adhered to.

Related Posts

-

Maximize Precision and Efficiency with Local Water Jet Cutting: The Future of Material Processing

-

Exploring the Benefits of Water Jet Cutting for Precision Stainless Steel Fabrication

-

Understanding the Benefits of Water Jet Cutting Machines in Modern Manufacturing

-

Unlocking Precision: How Water Jet Cutting Systems Revolutionize Metal Fabrication with 0.005-Inch Accuracy

-

2025 Top 5 Water Jet Cutting Accuracy Innovations for Precision Manufacturing

-

Top 10 Waterjet Cutting Parts for Precision Engineering Applications