How to Use Water Jet Cutting for Stainless Steel Projects?

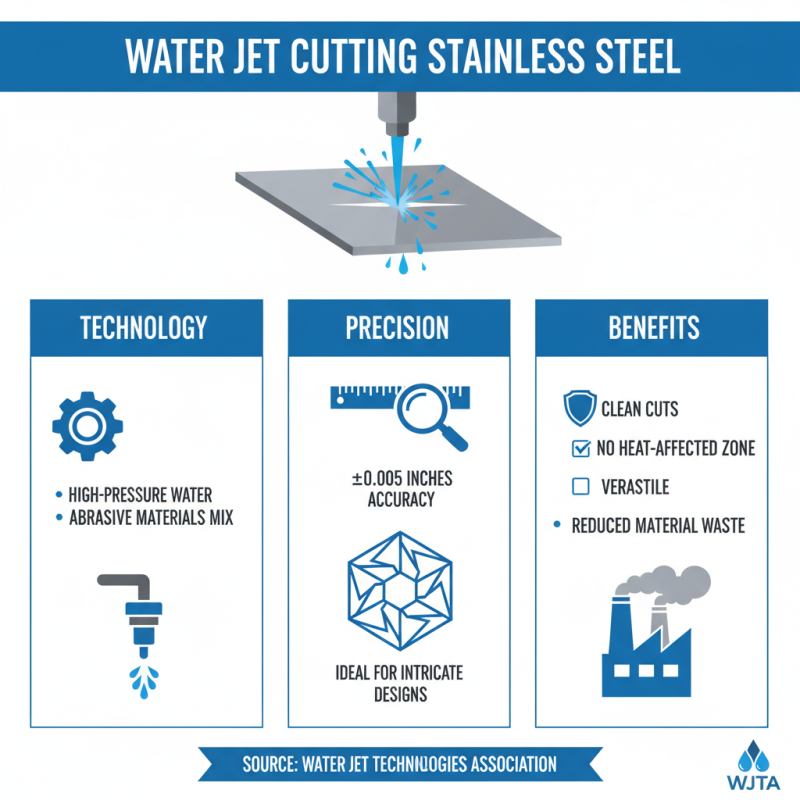

Water jet cutting stainless steel is a fascinating technique. It uses high-pressure water mixed with abrasive materials. This method creates intricate designs with precision. Many industries benefit from this approach.

In stainless steel projects, water jet cutting is often preferred. It offers clean edges without excessive heat. This reduces any risk of altering the metal's properties. However, not all designs translate well. Some complex patterns may pose challenges.

Choosing the right pressure and abrasive materials is crucial. A common mistake is rushing the settings. Experimentation may lead to imperfections. Understanding these nuances can elevate your project’s outcome. Always reflect on what worked and what didn’t. This will ultimately enhance your water jet cutting skills.

Understanding Water Jet Cutting Technology for Stainless Steel

Water jet cutting has revolutionized the way stainless steel is processed. This technology uses high-pressure water mixed with abrasive materials to cut through tough materials with precision. According to a report by the Water Jet Technologies Association, the accuracy of water jet cutting can be as precise as ±0.005 inches, making it ideal for intricate designs.

This method is favored in industries like aerospace and automotive. It effectively reduces thermal stress, so there are fewer material deformations. Studies indicate that water jet cutting can achieve clean edges without any secondary finishing. It can also handle various thicknesses of stainless steel, ranging from thin sheets to thick plates.

**Tip:** Proper equipment maintenance is vital. Regularly check pressure levels and replace worn nozzles. This ensures optimal performance and prolongs the life of your cutting machine.

While water jet cutting offers many advantages, there are limitations. The setup can be costly, and using the right abrasives is crucial. If not selected carefully, they can lead to increased operational costs. Some users might find it difficult to master the controls initially. Continuous training is essential to harness its full potential.

**Tip:** Pay attention to the alignment. Incorrect setups can lead to uneven cuts. Double-check measurements before starting your projects.

Benefits of Using Water Jet Cutting for Stainless Steel Projects

Water jet cutting is a game changer for stainless steel projects. This technique uses high-pressure water mixed with abrasives to create clean cuts. One of the main benefits is precision. The cutting process minimizes material waste, maximizing efficiency. Designers love these well-defined edges. There’s no heat-affected zone, so the metal retains its structural integrity.

Tips: Always measure twice before cutting. Double-check your design files to avoid costly mistakes. Maintaining your equipment is crucial. Regular maintenance enhances cutting efficiency.

Another significant advantage is versatility. Water jet cutting can tackle various shapes and sizes. The method works well with complex designs that traditional cutting can't manage. Not all projects suit this technique, but for intricate work, it shines.

Tips: Consider project limits. It's not the fastest method for simple cuts. Also, ensure proper water disposal after cutting. Some projects may encounter issues if debris isn't managed properly.

Essential Equipment Needed for Water Jet Cutting Process

Water jet cutting is effective for stainless steel projects. To start, you need some essential equipment. A water jet cutter is the main machine used. It generates a high-pressure stream of water mixed with abrasive material. This mixture can cut through stainless steel smoothly.

Another important piece of equipment is the pump. It boosts water pressure to create that powerful jet. A reliable pump ensures efficient cutting. You will also need a table or a workspace to support the material while cutting. It should be sturdy enough to handle the weight of stainless steel sheets.

Don’t forget safety gear. Protective goggles, gloves, and ear protection are essential. Working with high pressures can be dangerous. Additionally, be mindful of the cleanup process. Water and metal shavings can create a messy environment. Keeping your workspace tidy is crucial for safe operation. Sometimes things don't go as planned. Errors can happen. Reflecting on these mistakes helps improve your technique.

How to Use Water Jet Cutting for Stainless Steel Projects?

| Equipment | Description | Required for Cutting | Typical Usage |

|---|---|---|---|

| Water Jet Machine | Machinery that uses high-pressure water mixed with abrasive materials to cut through stainless steel. | Yes | Used for cutting complex shapes and designs. |

| Abrasive Material | Granular material (like garnet) that is mixed with water to assist cutting. | Yes | Enhances the cutting efficiency on hard materials. |

| Control System | Computer software to design and operate the water jet cutting machine. | Yes | Used for programming cuts and controlling the machine. |

| Protective Gear | Safety equipment including goggles, gloves, and ear protection. | Yes | Essential for operator safety during the cutting process. |

| Material Handling Equipment | Tools like cranes or hoists to manage heavy stainless steel sheets. | Recommended | Facilitates safe loading and unloading of materials. |

Step-by-Step Guide to Water Jet Cutting Stainless Steel

Water jet cutting is an effective method for working with stainless steel. It uses high-pressure water mixed with abrasive materials to cut through various thicknesses of metal. This technique produces clean edges and minimizes heat distortion. It's ideal for intricate designs or sensitive components.

Before starting, it’s important to prepare your stainless steel project. Measure and mark your design clearly. Make sure the surface is clean to avoid contamination. A lay-out can help visualize the cuts. Tips: Always double-check measurements before cutting. Mistakes can lead to wasted material.

During the cutting process, monitor the machine’s parameters closely. Adjust pressure settings if necessary. Keep an eye on the water flow to ensure consistent cuts. Not all machines work the same way. It may also take some practice to get the cut quality you desire. Remember, experimentation can lead to better results.

After cutting, inspect the edges. They might need some finishing work. Sanding could be required to remove jagged edges. With practice, you’ll find ways to improve your technique. Each project teaches you something new about water jet cutting.

Common Applications of Water Jet Cutting in Stainless Steel Fabrication

Water jet cutting is a versatile method used in stainless steel fabrication. It employs a high-pressure jet of water mixed with abrasives to slice through materials. This technique is popular in many industries, especially for intricate designs. Precision is key here. Often, projects require tight tolerances and perfect cuts. Water jet cutting can achieve that, but sometimes adjustments are necessary. Machine calibrations can vary, and skilled operators must monitor the process closely.

Common applications include architectural elements, industrial components, and custom parts. For instance, water jet cutting is ideal for creating intricate patterns in stainless steel sheets. It can produce detailed designs without causing thermal distortion. However, not every project is straightforward. Thickness can be an issue. Thicker materials require more advanced setups. Operators might face challenges, especially if settings are incorrect. Troubleshooting can become a crucial part of the workflow.

Additionally, some projects might reveal imperfections. Uneven edges or surface roughness may appear despite the technology used. This calls for post-processing steps. Polishing or grinding might be needed to achieve the desired finish. Embracing these challenges can lead to even better end results. Understanding the nuances of water jet cutting is essential for success. It’s not always perfect, but that leaves room for learning and improvement.

Water Jet Cutting Applications in Stainless Steel Projects

Related Posts

-

How to Use Water Jet Cutting for Steel: A Complete Guide

-

Exploring the Benefits of Water Jet Cutting for Precision Stainless Steel Fabrication

-

Top Benefits of Local Water Jet Cutting for Precision Manufacturing?

-

What is Local Water Jet Cutting and How Does It Work?

-

What is Plastic Water Jet Cutting and How Does It Work?

-

Maximize Precision and Efficiency with Local Water Jet Cutting: The Future of Material Processing