The Ultimate Guide to Understanding Lift Docks and Their Importance in Modern Logistics

In today's fast-paced logistics landscape, the efficiency of material handling systems is paramount to the success of supply chain operations. One crucial component that plays a significant role in this process is the lift dock, which serves as a vital interface between transport vehicles and warehouse facilities. According to a report by ARC Advisory Group, implementing advanced docking systems can reduce loading and unloading times by as much as 30%, significantly enhancing overall productivity. Furthermore, as e-commerce continues to expand, the demand for optimized logistics solutions has surged, with the global market for lift docks projected to reach $3 billion by 2025. Understanding the various types of lift docks and their functionalities is essential for logistics professionals aiming to improve operational efficiencies and accommodate the increasing volume of goods in transit. This guide aims to illuminate the importance of lift docks in modern logistics and their impact on supply chain effectiveness.

How to Choose the Right Lift Dock for Your Warehouse Efficiency

When selecting the right lift dock for your warehouse, it's crucial to consider the specific operational needs of your facility. According to a report by the Material Handling Industry of America (MHIA), warehouses can increase efficiency by up to 30% with the proper dock equipment. Factors such as load capacity, dock height, and lift type should align with your logistics goals. For instance, hydraulic lifts are known for their ability to handle heavier loads, making them suitable for warehouses dealing with bulk materials.

Additionally, the design of the lift dock can significantly impact safety and workflow. A study from the Occupational Safety and Health Administration (OSHA) noted that properly designed lift docks could reduce workplace accidents by approximately 25%. Features like adjustable height, safety barriers, and non-slip surfaces not only enhance worker safety but also streamline the loading and unloading process. Investing in the right lift dock not only optimizes operational flow but also protects your workforce, ultimately contributing to the success of your logistics operations.

How to Maximize Safety Protocols with Lift Dock Installations

In modern logistics, lift docks play a crucial role in facilitating the efficient movement of goods. However, safety protocols must be at the forefront during their installation and operation. According to the Occupational Safety and Health Administration (OSHA), around 25% of all warehouse injuries are attributed to loading dock incidents, emphasizing the need for rigorous safety measures. Companies can enhance safety by employing features such as dock levelers, bumpers, and adequate lighting to reduce the risk of accidents during loading and unloading operations.

Tips for Maximizing Safety Protocols:

1. Regular training sessions for employees on proper loading dock procedures can significantly lower risks. According to the National Safety Council, organizations that implement regular safety training see a 25% reduction in workplace incidents.

2. Installing advanced monitoring systems that alert staff to potential hazards, like weight limits or improper dock alignment, can help mitigate accidents. A report from the Logistics Management 2022 Safety Survey indicates that facilities with real-time monitoring systems reported a 30% decrease in dock-related injuries.

Continually assessing and improving lift dock safety protocols not only protects employees but also minimizes operational downtime. By prioritizing these measures, companies can ensure safer and more efficient logistics operations.

How to Optimize Your Supply Chain Using Advanced Lift Dock Solutions

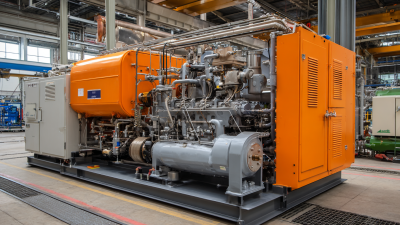

Lift docks play a crucial role in modern logistics by facilitating the efficient loading and unloading of goods. Advanced lift dock solutions enhance supply chain optimization by allowing for seamless movement of products between transport vehicles and warehouse floors. The increasing demand for efficient logistics operations has led to innovations in lift dock technology, including belt-driven elevating tables that cater to various load capacities and table sizes.

The market for belt-driven lift dock tables is projected to grow significantly, driven by diverse user industries such as manufacturing and warehousing. With options available for light to medium loads and various table dimensions, these solutions can be tailored to specific operational needs. Implementing upgraded mechanical equipment not only streamlines processes but also improves safety and productivity, making it an essential component of a modern supply chain strategy.

The Importance of Lift Docks in Modern Logistics

This chart illustrates the average loading efficiency (in seconds per pallet) of various types of lift docks over a period of five years. The data reflects the increasing importance of advanced lift dock solutions in optimizing supply chains.

How to Maintain and Service Your Lift Docks for Longevity

Maintaining lift docks is crucial for ensuring their longevity and operational efficiency in modern logistics. According to a report by the Material Handling Industry of America (MHIA), improperly maintained lift docks can lead to a decrease in productivity by up to 20%. Regular inspections and timely servicing can mitigate these risks. An effective maintenance schedule should involve checking the hydraulic systems, inspecting for wear and tear on docking seals, and ensuring that safety mechanisms are functioning properly. According to a study published by the National Safety Council, facilities that adhere to a strict maintenance routine see a significant reduction in accidents related to lift operations.

Additionally, the importance of keeping lift docks in optimal condition cannot be overstated. The Forklift Truck Association suggests that proactive maintenance can extend the lifespan of lift docks by an impressive 30%. This involves not only mechanical inspections but also maintenance of the surrounding environment to prevent contamination from moisture or debris. Operators should also train their staff on correct docking procedures, as improper use can lead to early wear and costly repairs. With the increasing demands of e-commerce and logistics, investing in the upkeep of lift docks is not just beneficial; it’s essential for maintaining a competitive edge in the industry.

How to Train Staff on Best Practices for Using Lift Docks Effectively

Training staff on best practices for using lift docks effectively is crucial for ensuring safety and optimizing logistics operations. First, staff should receive comprehensive training that covers the basic functions and safety protocols associated with lift docks. This includes understanding weight limits, proper loading techniques, and the importance of wearing appropriate personal protective equipment. Demonstrating how to use various types of lift dock equipment can help team members become proficient and confident in their roles.

Moreover, regular refresher courses and hands-on practice sessions can reinforce the skills learned. These sessions should include simulated scenarios where employees encounter common issues, such as balancing loads or responding to potential hazards. Encouraging open communication among team members allows them to share experiences and tips, cultivating a culture of safety and efficiency. By prioritizing ongoing education and practical training, organizations can significantly reduce the risk of accidents and enhance the overall effectiveness of their logistics operations.

Related Posts

-

Understanding the Benefits of Water Jet Cutting Machines in Modern Manufacturing

-

The Future of Precision Manufacturing with Waterjet Cutting Technology in Utah

-

Exploring the Benefits of Water Jet Cutting for Precision Stainless Steel Fabrication

-

Maximize Precision and Efficiency with Local Water Jet Cutting: The Future of Material Processing

-

The Future of Cutting Technologies Exploring the Benefits of Water Jet Abrasive Systems

-

The Ultimate Guide to Choosing the Right Disk Mower for Your Lawn Care Needs