The Ultimate Guide to Choosing the Best Waterjet Machine in 2025

In the rapidly evolving landscape of manufacturing technology, choosing the right waterjet machine has become increasingly critical for businesses aiming to enhance their production capabilities. As we step into 2025, the advancements in waterjet cutting technology present a myriad of options that cater to diverse industrial needs. With applications ranging from precision cutting in metal and glass to intricate designs in stone and textiles, understanding the various features and specifications of waterjet machines is essential for making an informed decision.

When selecting a waterjet machine, factors such as cutting speed, accuracy, and material compatibility must be taken into consideration. Additionally, the integration of automation and software solutions can vastly improve efficiency and productivity. This guide will delve into these considerations, providing insights into the key attributes that should influence your choice of a waterjet machine. By equipping yourself with the right knowledge, you can ensure that your investment not only meets current operational demands but also positions you favorably for future growth in a competitive market.

Understanding Waterjet Technology: Key Concepts and Applications

Waterjet technology is at the forefront of advanced manufacturing processes, leveraging the power of high-pressure water mixed with abrasives to cut through a variety of materials. This non-thermal cutting method is particularly valued for its ability to maintain the integrity of materials, minimizing heat-affected zones that can lead to warping or structural damage. According to a report by the Market Research Future, the global waterjet cutting machine market is projected to reach USD 1.5 billion by 2025, underscoring the technology's growing adoption across industries such as aerospace, automotive, and metal fabrication.

Understanding key concepts of waterjet technology is essential for selecting the right machine for specific applications. The core components include the high-pressure pump that generates pressures typically between 30,000 to 90,000 psi, and the cutting nozzle where the waterjet is formed. Applications range from cutting delicate materials like glass and textiles to robust materials such as steel and granite, highlighting the versatility of the technology. Additionally, advancements in five-axis waterjet systems allow for complex geometries and intricate designs, further expanding the capabilities and applications in sectors that require precision, such as medical device manufacturing and custom-engineered parts.

Important Factors to Consider When Selecting a Waterjet Machine

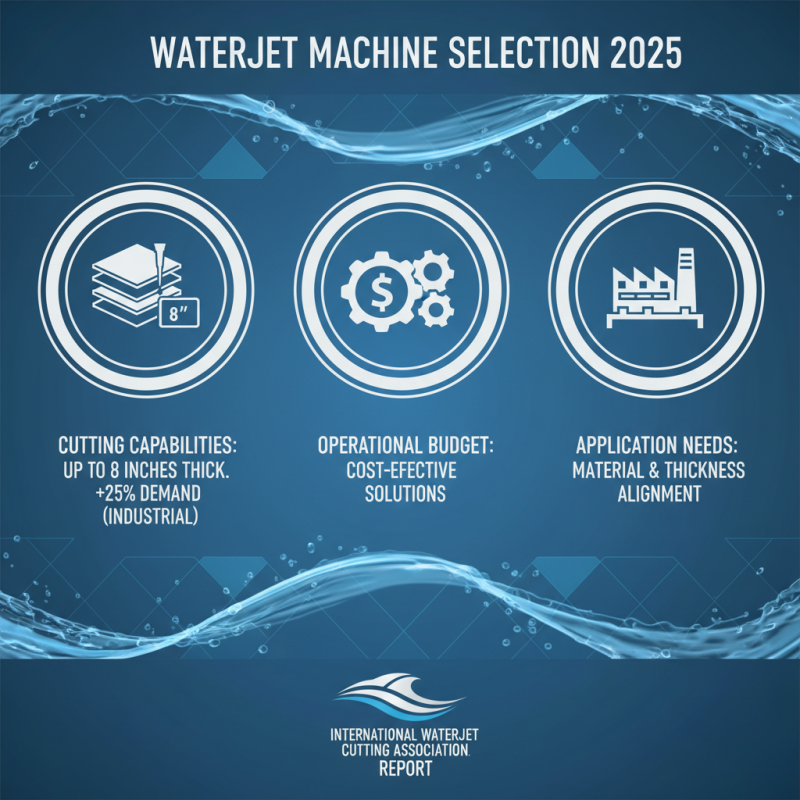

When selecting a waterjet machine in 2025, there are several important factors to consider to ensure that it meets your operational needs and budget constraints. First and foremost, the cutting capabilities of the machine should align with the materials and thicknesses you intend to work with. A report from the International Waterjet Cutting Association indicates that machines capable of cutting materials up to 8 inches thick have seen a 25% increase in demand due to the growing complexity of industrial applications.

Another critical aspect is the accuracy and precision of the waterjet machine. Factors such as the type of pump and the nozzle design significantly influence the cutting quality. According to a study by the Institute for Advanced Manufacturing, waterjet machines that operate at pressures above 60,000 psi can achieve tolerances within +/- 0.005 inches, making them ideal for high-precision industries such as aerospace and automotive.

Tips: Before making a purchase, consider running a cost-benefit analysis involving downtime, maintenance costs, and the expected lifespan of the machine. Additionally, assess the availability of customer support and service to ensure you can keep your waterjet machine operating smoothly.

Lastly, energy consumption is an essential factor that often goes overlooked. Efficient waterjet machines can lead to significant savings in operational costs, as reports suggest that energy-efficient models can reduce energy costs by as much as 30%. Choose a machine with energy-saving features to maximize long-term benefits for your production environment.

Comparing Different Types of Waterjet Machines: Pros and Cons

When selecting the best waterjet machine, understanding the different types available is crucial. Waterjet machines typically fall into two categories: abrasive and pure water jet systems. Abrasive waterjets are ideal for cutting harder materials like metals and stone, achieving precision cuts with a trade-off of higher operational costs due to the abrasive materials used. According to industry data from the Waterjet Technology Association, these systems can cut materials up to 100 inches thick, making them indispensable in heavy industries, but the abrasive materials can increase maintenance needs and operating expenses.

On the other hand, pure water jet machines, utilizing just water and pressure, are designed for softer materials such as rubber and foam. The advantage here is lower operational costs and reduced wear on machinery. However, they typically lack the cutting power required for more robust materials, limiting their use in heavyweight applications. A report from Market Research Future indicates that the growth rate of pure waterjet technology stands at approximately 5% annually, emphasizing its niche yet valuable market segment.

**Tips:** When choosing a machine, evaluate the materials you will frequently cut to ensure you select a system that meets those needs effectively. Also, consider the cost of consumables and the potential for future upgrades; a scalable system may serve your business better in the long run. Finally, always assess the machine's maintenance requirements, as this can significantly influence total operational costs over time.

The Ultimate Guide to Choosing the Best Waterjet Machine in 2025 - Comparing Different Types of Waterjet Machines: Pros and Cons

| Type of Waterjet Machine | Pros | Cons | Typical Uses | Price Range |

|---|---|---|---|---|

| Abrasive Waterjet | Versatile, fast cutting, can cut thick materials | Higher operating costs, requires abrasive materials | Metal, stone, glass cutting | $100,000 - $500,000 |

| Pure Waterjet | Lower cost, doesn't require abrasives, ideal for softer materials | Limited to softer materials, slower cutting | Food industry, paper, plastics | $50,000 - $300,000 |

| 5-Axis Waterjet | Complex shapes, high precision, versatile | Very high initial investment, requires skilled operators | Aerospace, automotive, intricate designs | $200,000 - $1,000,000 |

| Robotic Waterjet | Flexible configurations, great for automation | Higher maintenance, programming complexity | Manufacturing, custom parts | $150,000 - $800,000 |

Analyzing the Cost of Ownership for Waterjet Machines in 2025

When considering the acquisition of a waterjet machine in 2025, understanding the cost of ownership is crucial for making an informed decision. The initial purchase price is only the tip of the iceberg; potential buyers must factor in maintenance, operational costs, and the lifespan of the machine. Regular maintenance can help prolong the machine's life and ensure optimal performance, but it does come with its own set of costs. Additionally, consumables like abrasives, water, and power consumption can accumulate over time, influencing the overall expenditure significantly.

Tips: To minimize operational costs, consider implementing a scheduled maintenance plan that aligns with the manufacturer's recommendations. Regular checks can prevent unexpected breakdowns and extend the lifespan of the machine. Moreover, researching energy-efficient models can reduce electricity costs in the long run, which is an often-overlooked aspect of ownership.

Another factor worth examining is the resale value of a waterjet machine. Some machines might depreciate faster than others, reflecting their build quality or technological advancements. When assessing total cost ownership, it’s beneficial to research historical resale values of similar machines and consider how advancements in technology could affect the value over time. This foresight can aid in making a more knowledgeable investment that aligns with long-term operational goals.

The Ultimate Guide to Choosing the Best Waterjet Machine in 2025

This chart illustrates the projected cost of ownership for different types of waterjet machines in 2025. The data shows the average estimated costs in USD over a typical operational lifespan, including initial purchase, maintenance, and operational expenses.

Future Trends in Waterjet Technology: What to Expect in the Coming Years

The future of waterjet technology is poised for significant advancements in the coming years, driven by innovations in automation and materials science. According to a report by MarketsandMarkets, the global waterjet cutting machine market is expected to grow at a CAGR of 7.2% from 2020 to 2025, underscoring the increasing demand for precision cutting solutions across various industries. One of the key trends emerging is the integration of Artificial Intelligence (AI) and machine learning into waterjet systems, enabling more efficient operation and improved cut quality. These smart machines will analyze cutting patterns and optimize parameters in real-time, ultimately reducing waste and enhancing productivity.

Furthermore, advancements in material technology are also set to revolutionize the waterjet cutting process. With the introduction of high-performance abrasives and composites, waterjet machines will be capable of cutting through tougher materials with remarkable accuracy. Research indicates that the efficiency of cutting complex geometries is anticipated to increase by up to 30% due to improvements in the nozzle design and water pressure systems. As companies continue to seek sustainable manufacturing solutions, waterjet technology, known for its minimal waste generation and energy efficiency, will become increasingly attractive, solidifying its position as a critical tool for modern manufacturing.

Related Posts

-

Top Benefits of Waterjet Cutting for Your Manufacturing Needs

-

10 Essential Tips for Effective Waterjet Cutting: Maximize Precision and Efficiency

-

2025 Top 5 Water Jet Cutting Accuracy Innovations for Precision Manufacturing

-

Exploring the Benefits of Water Jet Cutting for Precision Stainless Steel Fabrication

-

The Ultimate Guide to Understanding How a Water Jet Head Transforms Industrial Cutting

-

What is a Jet Cutting Machine and How Does It Work in Manufacturing