2026 Top Trends in Waterjet Cutting Aluminum Techniques?

In the world of manufacturing, waterjet cutting aluminum is transforming how industries approach design. This versatile technique has gained popularity due to its precision and efficiency. It allows for intricate cuts, making it ideal for complex projects.

As we look ahead to 2026, several trends are emerging in waterjet cutting aluminum practices. Innovations in technology are enhancing speed and accuracy. New materials are being integrated, expanding the applications of this cutting method.

However, the industry faces challenges. Operators must continually upgrade their skills to keep up with advancements. Additionally, businesses must consider the environmental impact of their operations. Reflecting on these aspects will be vital for success in the coming years.

Emerging Waterjet Cutting Technologies for Aluminum in 2026

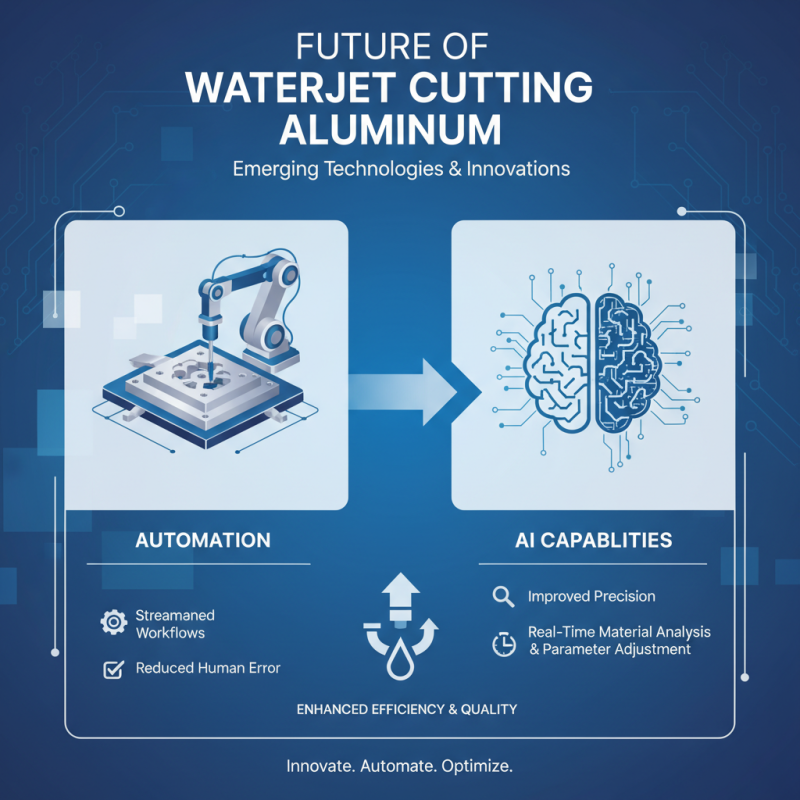

As we look into the future of waterjet cutting aluminum techniques, several emerging technologies stand out. Innovations in automation are one area to watch. Automated systems can streamline workflow and reduce human error. Machines equipped with AI capabilities improve precision. These systems can analyze materials and adjust parameters in real time.

Another trend involves hybrid technologies. Combining waterjet cutting with laser technology offers enhanced versatility. This method allows for sharper cuts and can handle varied thicknesses. It improves efficiency and enhances overall output. Such advancements could revolutionize how aluminum is processed, providing greater possibilities for designers and engineers.

Tips: Regular maintenance is crucial for waterjet systems. Regular checks can prevent costly downtimes. Additionally, training staff on new technologies can maximize their potential.

The landscape is changing rapidly, and staying ahead may require continuous learning. Experimenting with new techniques can lead to unexpected improvements. Embrace the evolving nature of technology, but be prepared for challenges, as not every change will yield immediate results. Adaptation might be necessary.

Advancements in Precision and Efficiency for Waterjet Cutting Techniques

Waterjet cutting is revolutionizing the aluminum manufacturing industry. The advancements in precision are impressive. Newer machines offer tighter tolerances, enabling intricate designs. This precision reduces waste significantly, which is economically beneficial. Fine details, like complex shapes and narrow cuts, are now achievable.

Efficiency is another key focus area. Waterjet systems have become faster. Increased pump pressures are helping to cut through aluminum more quickly. However, the energy consumption of high-speed operations raises concerns. Balancing speed with sustainability is a challenge.

As technology evolves, continuous improvement is needed. Not all innovations deliver as promised. The learning curve for operators can be steep. Emphasizing user training is crucial. It’s vital to adapt to new techniques for optimal performance. Embracing change will enhance productivity and quality in waterjet cutting.

2026 Top Trends in Waterjet Cutting Aluminum Techniques

Sustainable Practices in Waterjet Cutting Aluminum Manufacturing

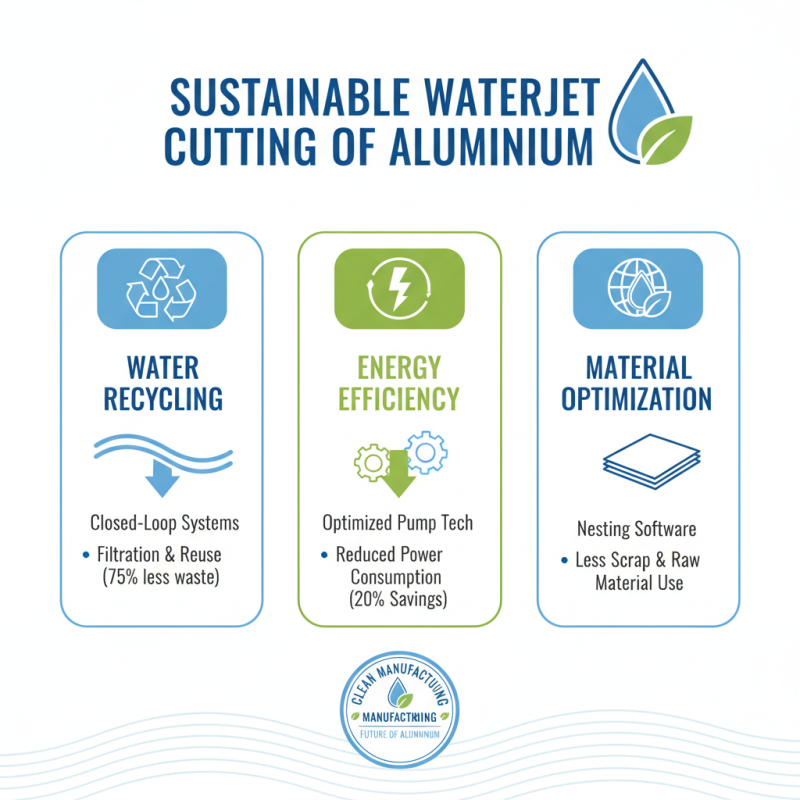

Sustainable practices in waterjet cutting of aluminum are crucial in today's manufacturing landscape. Aluminum cutting uses vast amounts of water and energy. According to the Waterjet Industry Association, nearly 25% of water is wasted in traditional processes. This raises concerns about resource management.

Innovations in water recycling systems can significantly curb this wastage. Using closed-loop systems, manufacturers can reuse up to 90% of the water. However, only a minority of companies have made this transition. Many still rely on outdated techniques, neglecting the potential benefits of sustainable solutions.

Energy efficiency is another pressing issue. Waterjet cutting typically consumes a lot of power. Upgrading to high-efficiency pumps can reduce energy usage by approximately 30%. Yet, resistance to change is common. Some firms hesitate, fearing high initial costs. But the long-term savings and environmental impact are worth reconsidering. The industry needs to reflect on these practices to truly embrace sustainable growth.

Impact of Automation and Robotics on Waterjet Cutting Processes

Automation and robotics are reshaping waterjet cutting processes. Many industries are adopting these technologies to enhance productivity. According to a recent market report, the global market for automated cutting systems is expected to reach $2.3 billion by 2026. This growth highlights the shift toward efficiency and precision in metal fabrication, particularly in aluminum cutting.

The integration of robotics in waterjet cutting improves accuracy. Robotic arms can maneuver with exceptional precision, reducing material waste. A study indicated that automation can decrease operational costs by 20-30%. These machines can operate continuously, often outpacing manual labor. However, the upfront investment for automation technology can be significant. Smaller companies may find it challenging to adopt these systems due to budget constraints.

Moreover, maintaining these automated systems requires training. Skill gaps in the workforce can hinder the full potential of automation. Employees need to adapt to new technologies constantly. Industry reports show that companies investing in workforce education can see a boost in efficiency. There is a pressing need for collaboration between technology providers and training institutions. This way, firms can better harness the benefits of automation while minimizing hurdles.

2026 Top Trends in Waterjet Cutting Aluminum Techniques

| Trend | Description | Impact of Automation | Impact of Robotics | Predicted Growth (2026) |

|---|---|---|---|---|

| Advanced Control Systems | Integration of sophisticated software for precision cutting. | Enhances accuracy and reduces waste. | Increases consistency in operations. | 30% |

| Eco-Friendly Practices | Use of recycled water and sustainable materials in processes. | Reduces operational costs and environmental impact. | Facilitates the integration of cleaner technologies. | 25% |

| AI-Driven Analytics | Utilization of AI to predict maintenance needs and optimize cutting paths. | Increases machine uptime and efficiency. | Automates decision-making processes in cutting. | 40% |

| Integration with CAD/CAM | Seamless integration of design software with cutting machines. | Enhances workflow and reduces project lead times. | Allows for more complex designs to be cut with ease. | 35% |

| Remote Operations | Ability to control waterjet systems remotely via IoT. | Facilitates maintenance and monitoring from anywhere. | Enables autonomous workflows to some extent. | 20% |

Trends in Software Integration for Waterjet Cutting Aluminum Operations

In the evolving landscape of waterjet cutting,

software integration holds pivotal importance. Modern waterjet systems are equipped with

advanced software that enhances efficiency. These programs streamline

design-to-production workflows. They facilitate real-time monitoring

and analysis of the cutting process. This integration allows for quick adjustments,

reducing the risk of errors in aluminum cutting.

One tip for successful software use is to invest time in training.

Understanding the software capabilities can significantly impact outcomes.

Take advantage of tutorials and support resources.

This can minimize learning curves and improve productivity in the workshop.

Additionally, ensure your software is regularly updated.

Updates often introduce new features that can enhance your operations.

While technology offers remarkable benefits, it is not flawless.

Bugs or system failures can disrupt cutting operations unexpectedly.

Regular checks and maintenance are essential.

Adopt a proactive approach to troubleshooting.

Document common issues and resolutions for future reference.

This practice fosters a more resilient operational environment.

Ultimately, seamless software integration can transform aluminum cutting processes when managed effectively.

Related Posts

-

Understanding the Benefits of Jet Cut Technology in Modern Manufacturing

-

Top 10 Advantages of Using Waterjet Garnet for Precision Cutting in Industries

-

Why Choose Waterjet Cutting Services in Seattle for Your Precision Needs?

-

Top Tips for Maintaining Waterjet Cutting Parts for Optimal Performance

-

10 Essential Tips for Effective Waterjet Cutting: Maximize Precision and Efficiency

-

Why is Waterjet Cutting the Best Choice for Precision Manufacturing