How to Select the Right Waterjet Cutting Parts for Your Project?

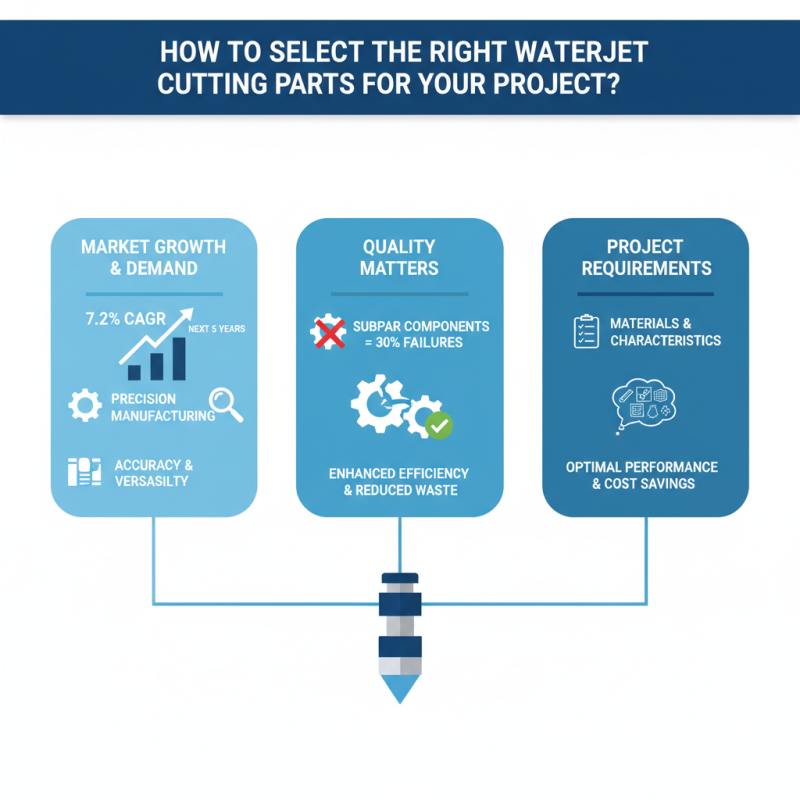

In the world of precision manufacturing, selecting the right waterjet cutting parts is crucial. Market research indicates that waterjet cutting is projected to grow at a CAGR of 7.2% over the next five years. This growth reflects the increasing demand for accuracy and versatility in various industries. Waterjet cutting parts must match the specific needs of your project for optimal performance.

The importance of quality in waterjet cutting parts cannot be overstated. Subpar components can lead to inefficiencies and costly downtime. A report from XYZ Engineering suggests that up to 30% of operational failures stem from inadequate parts. This statistic underscores the need for careful selection. Matching the right parts with the application can enhance efficiency and reduce waste.

It's essential to reflect on project requirements before making a decision. Not every component will suit every task. Understanding the materials involved and their characteristics can influence the choice of waterjet cutting parts. Ignoring these factors can lead to unsatisfactory results and increased costs. Taking the time to evaluate your specific needs will pay off in the long run.

Understanding Waterjet Cutting Technology and Its Applications

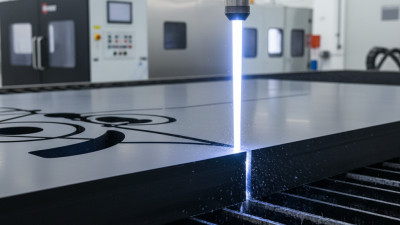

Waterjet cutting technology utilizes high-pressure water to cut through various materials. This method is known for its precision and versatility. It is commonly used in industries like aerospace, automotive, and construction. A waterjet can cut metals, glass, ceramic, and even food. Understanding how this technology works is vital for selecting appropriate cutting parts.

The heart of waterjet cutting is the nozzle, which focuses water into a fine stream. The quality of the nozzle affects the accuracy of the cut. If the nozzle becomes worn, it might lead to uneven cuts. Operators should regularly inspect and replace nozzles for optimal performance. The abrasive material used in some applications is equally important. Selecting the right abrasive can significantly impact the efficiency and quality of the final product. Not every project requires the same type of abrasive, so it’s essential to assess specific needs.

Mistakes can happen. Using the wrong parts may lead to delays or increased costs. Monitoring the cutting process helps in identifying issues early. Operators should maintain open communication with their team. Understanding the intricacies of waterjet cutting can improve overall project outcomes. Every choice counts, and reflecting on past experiences aids better decision-making for future projects.

Waterjet Cutting Parts Selection: A Comparative Analysis

Key Factors to Consider When Choosing Waterjet Cutting Parts

When choosing waterjet cutting parts, it's crucial to consider material compatibility. Different materials, like metals and plastics, require specific parts to achieve optimal results. Researching which parts work best for your chosen material will save time and enhance efficiency.

Another key factor is the intended application's precision requirements. Some projects demand high accuracy, while others may allow for more flexibility. Understanding the level of precision needed will guide you in selecting the right components.

Tips: Always discuss your project with experts. They can provide insights on part durability and performance. Additionally, consider the pressure ratings of the parts. Parts rated for higher pressure often last longer.

Finally, never overlook maintenance capabilities. Parts that are hard to maintain can lead to downtime and increased costs. Reflect on the long-term implications of your choices. Balancing performance and ease of maintenance is critical for project success.

Material Compatibility: Selecting the Right Nozzle and Abrasives

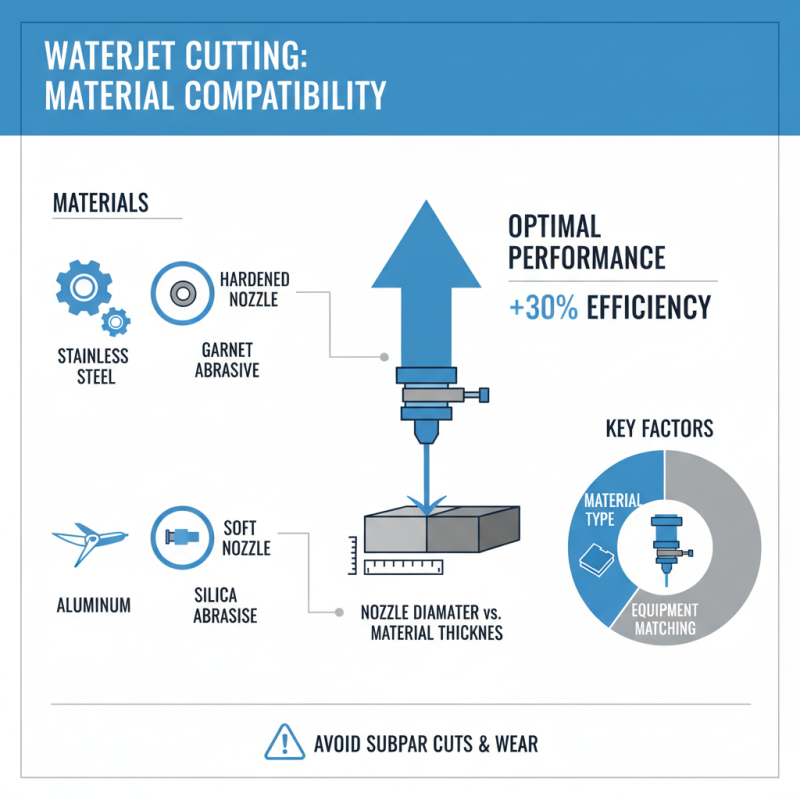

When selecting waterjet cutting parts, material compatibility is crucial. Different materials require specific nozzles and abrasives to achieve optimal performance. For instance, stainless steel and aluminum need different approaches. Industry reports suggest that using the correct nozzle can increase cutting efficiency by up to 30%. It’s essential to match the nozzle diameter with the material thickness to prevent subpar cuts or excessive wear on the equipment.

Abrasives are equally important. Garnet is often favored for its effectiveness with a variety of materials. However, not all garnets are created equal. Some may have impurities that affect performance. A study indicated that using high-quality garnet can boost cutting speed by 20% compared to lower-grade alternatives. Employing the proper abrasive can also reduce the frequency of nozzle clogs, which are a common source of frustration in waterjet cutting.

Choosing the wrong parts can lead to complications, such as inconsistent cuts and increased operational costs. Many operators overlook the significance of compatibility. A mismatched abrasive can damage the nozzle and compromise the entire cutting process. Taking the time to assess material properties and consult reliable data can make a significant difference in project outcomes.

Evaluating Manufacturer Specifications for Optimal Performance

When selecting waterjet cutting parts, manufacturer specifications play a crucial role. Check the materials used in construction. High-quality materials often lead to better durability and performance. Look at the tolerances and dimensional accuracy provided by the manufacturer. These factors can significantly affect the end results of your project. Some manufacturers may have vague specifications, leaving you guessing about their true capabilities.

Another vital consideration is the compatibility of parts. Ensure that the parts will seamlessly integrate with your existing setup. Sometimes, manufacturers may fail to provide clear information about compatibility, which can be frustrating. You could end up with components that don’t fit well or perform poorly.

In addition, consider the expected lifespan of the parts. Many manufacturers oversell the longevity of their components. Reading user reviews can provide real-world insights. This helps you avoid potential pitfalls early in your selection process. Finally, also think about the support offered post-purchase. Some may leave you hanging once the sale is done. Detailed specifications are essential, but support can be just as important for your project’s success.

Cost-Effectiveness: Balancing Quality and Budget in Waterjet Parts

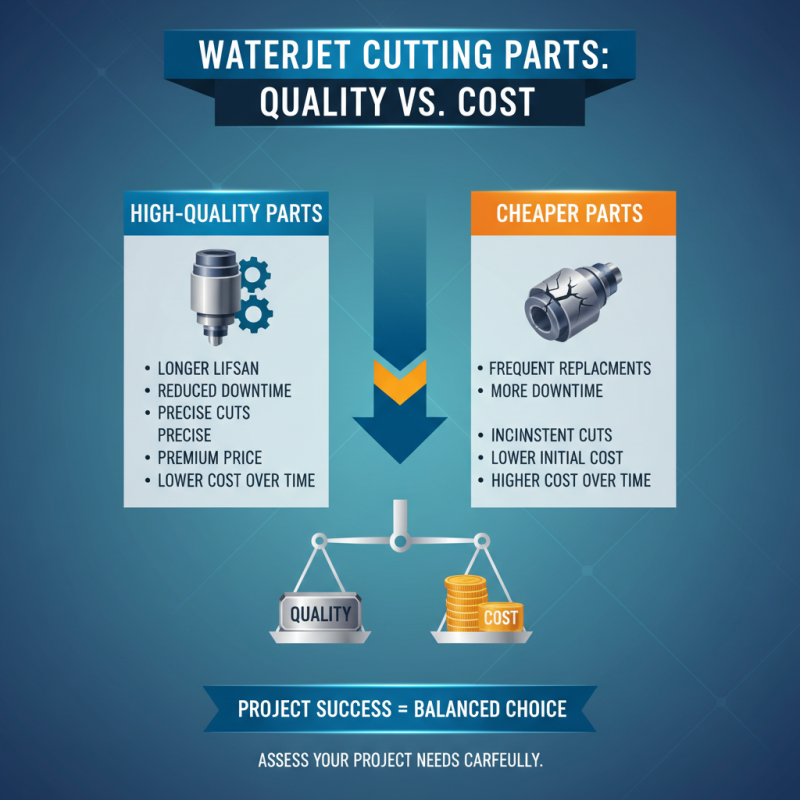

Selecting the right waterjet cutting parts is crucial for project success. Balancing quality and cost can be challenging. Higher-quality parts often last longer, but they may come at a premium. However, cheaper alternatives can lead to frequent replacements, resulting in higher costs over time. It’s essential to assess your specific project needs carefully.

Tips: Always check specifications before making a purchase. This ensures compatibility with your waterjet system. Consider the maintenance costs of each part, not just the initial price. A part that seems affordable might require more frequent repairs, which can add to overall expenses.

Project managers frequently face budget constraints. It's vital to identify which components are critical for optimal performance. Focus on key parts, such as nozzles or abrasives, that directly impact cutting quality. Sometimes, opting for slightly better quality in these areas can enhance overall efficiency. Keep in mind that investing wisely now might save money later. Being analytical here is better than choosing blindly.

Related Posts

-

Why is Waterjet Cutting the Best Choice for Precision Manufacturing

-

The Future of Precision Manufacturing with Waterjet Cutting Technology in Utah

-

Why Choose Waterjet Cutting Services in Seattle for Your Precision Needs?

-

Top Tips for Maintaining Waterjet Cutting Parts for Optimal Performance

-

2026 Best Waterjet Cutting Aluminum Techniques for Precision Manufacturing?

-

How to Use Waterjet Cutting for Rubber Applications?