What is Plastic Water Jet Cutting and How Does It Work?

In the world of manufacturing, precision matters. Plastic water jet cutting has emerged as a crucial technique. According to Dr. Emily Chen, an expert in cutting technologies, “Plastic water jet cutting allows for intricate designs with minimal waste.” This highlights the efficiency of this method.

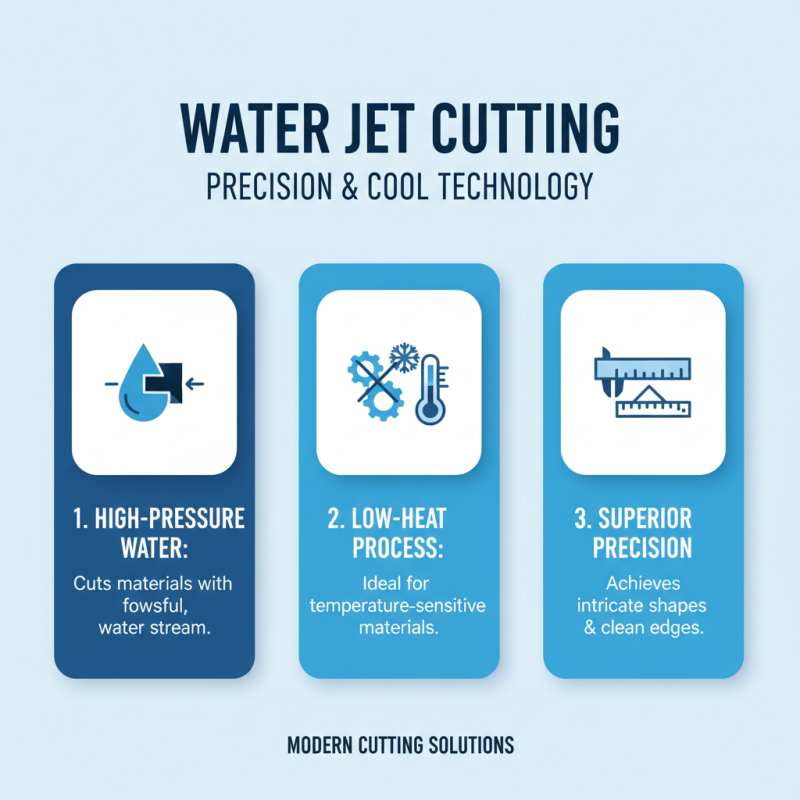

The process uses high-pressure water jets to slice through various plastic materials. This technology is favored for its ability to maintain precise edges without introducing heat. Heat can warp or damage certain plastics, making traditional cutting methods less efficient. The versatility of plastic water jet cutting is noteworthy, supporting complex shapes and patterns.

However, the challenge lies in the equipment's initial cost and maintenance. Many industries hesitate to adopt this technology due to the investment required. Not every establishment has access to skilled operators who can handle these machines expertly. Despite these issues, the benefits of precision and reduced waste make it worthy of exploration.

What is Plastic Water Jet Cutting?

Plastic water jet cutting is a precise manufacturing technique. It utilizes high-pressure water mixed with abrasive particles to cut through various materials. This method is particularly useful for plastics, which can be challenging to cut using conventional tools. The jet of water can reach pressures of up to 60,000 psi, making it effective for intricate designs.

The benefits of plastic water jet cutting are significant. It produces smooth edges and reduces the risk of thermal damage. A report from the WaterJet Cutting Association highlights that this method can increase productivity by up to 30% compared to traditional cutting methods. However, there are challenges. The initial setup costs can be high, and operators need training to maximize efficiency. Some might find the maintenance of the equipment complicated as well.

Despite its advantages, not all plastic types are suitable for this method. For instance, softer plastics may deform under high pressure. Additionally, the environmental impact of abrasive materials must be considered. Therefore, while plastic water jet cutting is innovative, it requires careful evaluation to ensure optimal application.

The Working Principle of Water Jet Cutting Technology

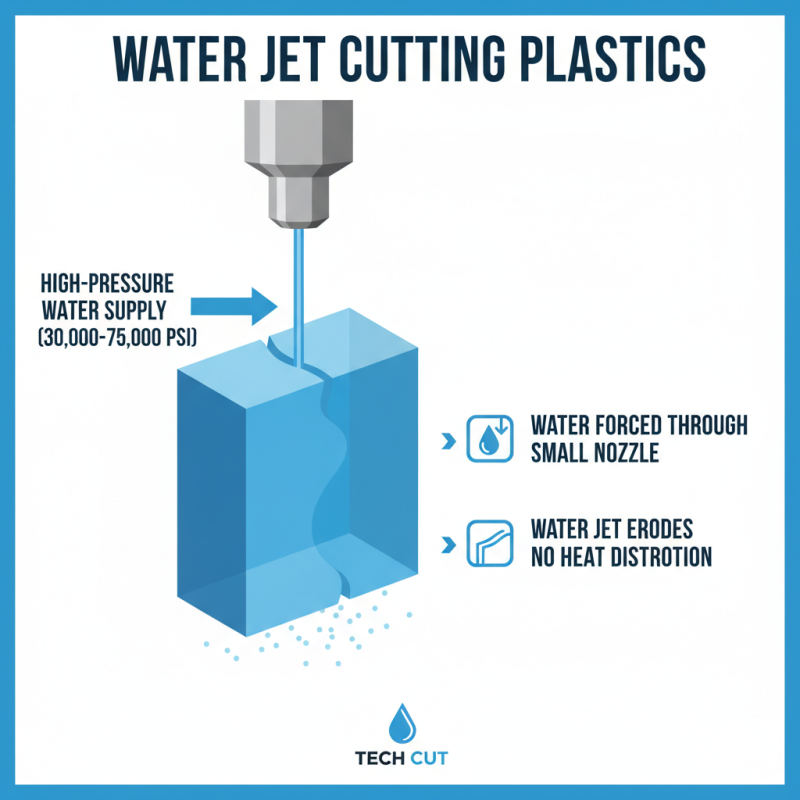

Water jet cutting technology utilizes a high-pressure stream of water to cut through various materials, including plastics. This method operates by forcing water through a small nozzle at extremely high pressures, typically between 30,000 and 75,000 psi. When the water exits the nozzle, it accelerates, creating a jet that can erode materials like plastic effectively. The effectiveness of the cutting process relies on the water's speed and pressure, allowing it to produce clean edges without heat distortion.

One notable aspect is that water jet cutting can incorporate abrasives. Adding materials like garnet enhances its cutting capabilities, especially for thicker plastics. According to industry reports, this method can achieve tolerances as tight as ±0.005 inches, depending on the material and thickness. The precision provided by water jet cutting is crucial in industries like automotive and aerospace, where accuracy is paramount. It also minimizes waste, making it an attractive option for environmentally conscious companies.

Despite its advantages, the technology has limitations. For instance, water jet cutting may not be suitable for all types of plastic. Some materials can swell or warp when exposed to water. Additionally, while the process is energy-efficient, the initial setup cost can be high. Yet, businesses often find the long-term benefits outweigh these drawbacks, reinforcing the value of water jet cutting in modern manufacturing.

Benefits of Using Water Jet Cutting for Plastics

Water jet cutting has revolutionized the way we work with plastics. This method uses high-pressure water mixed with abrasive particles to cut through materials. The precision of water jet cutting makes it ideal for delicate plastic components. It maintains edge integrity and prevents warping caused by heat. Many industries benefit from this process, especially when intricate designs are required.

Choosing water jet cutting for plastics comes with numerous benefits. One advantage is its versatility. It can handle various types of plastics, including acrylics and PVC. This flexibility allows manufacturers to create complex shapes with ease. Additionally, the process is environmentally friendly. It does not produce harmful fumes or waste, making it a sustainable option.

Tips for improving your water jet cutting process include regularly maintaining equipment. A well-kept machine ensures optimal performance. Also, consider the type of abrasive used. Different materials can affect the cutting quality. Lastly, always test new designs on scrap materials first. This helps avoid mistakes and wasted resources. This process has its challenges, but embracing these tips can lead to a more efficient workflow.

Applications of Plastic Water Jet Cutting in Various Industries

Plastic water jet cutting is a versatile technique used across various industries. It uses high-pressure water to cut plastic materials with precision. This method is particularly popular in manufacturing, automotive, and aerospace sectors. The ability to create complex shapes without melting the material is a significant advantage. For example, intricate parts in vehicles and aircraft often rely on this cutting method.

In the medical industry, plastic water jet cutting plays a critical role. Surgical instruments, medical devices, and components require exact specifications. The process ensures uniformity and reduces waste. Moreover, the absence of heat during cutting helps maintain the integrity of sensitive materials. This is crucial in applications where contamination has to be avoided.

Tips: Always consider material thickness before cutting. Thicker plastics may require adjustments in pressure settings. Also, regularly maintain your water jet equipment. This will prevent unexpected downtimes or faulty cuts. Lastly, testing cut samples can help in refining processes. Remember, trial and error can lead to better results over time.

Comparison of Water Jet Cutting with Other Cutting Methods

Water jet cutting is a precise method using high-pressure water to cut various materials. It stands out among cutting techniques. Compared to traditional cutting tools, water jet cutting generates less heat. This property makes it ideal for materials sensitive to temperature changes.

When deliberating on water jet cutting and laser cutting, differences emerge. Laser cutting has a narrow kerf, which allows for intricate designs but creates a heat-affected zone. This can distort thin materials. In contrast, water jet cutting uses a wider kerf. This wider cut may not be suitable for extremely intricate patterns. Plus, the requirement for a garnet abrasive can complicate the process.

Plasma cutting represents another method. It employs ionized gas to cut through metal. However, it can produce significant heat and slag. This can lead to unwanted surface imperfections. Water jet cutting avoids these drawbacks while delivering clean edges. Each method has its pros and cons, and it’s essential to choose wisely based on the project needs.

Related Posts

-

How to Use Water Jet Cutting for Steel: A Complete Guide

-

Maximize Precision and Efficiency with Local Water Jet Cutting: The Future of Material Processing

-

What is Local Water Jet Cutting and How Does It Work?

-

Exploring the Benefits of Water Jet Cutting for Precision Stainless Steel Fabrication

-

Understanding the Benefits of Water Jet Cutting Machines in Modern Manufacturing

-

Top Benefits of Local Water Jet Cutting for Precision Manufacturing?