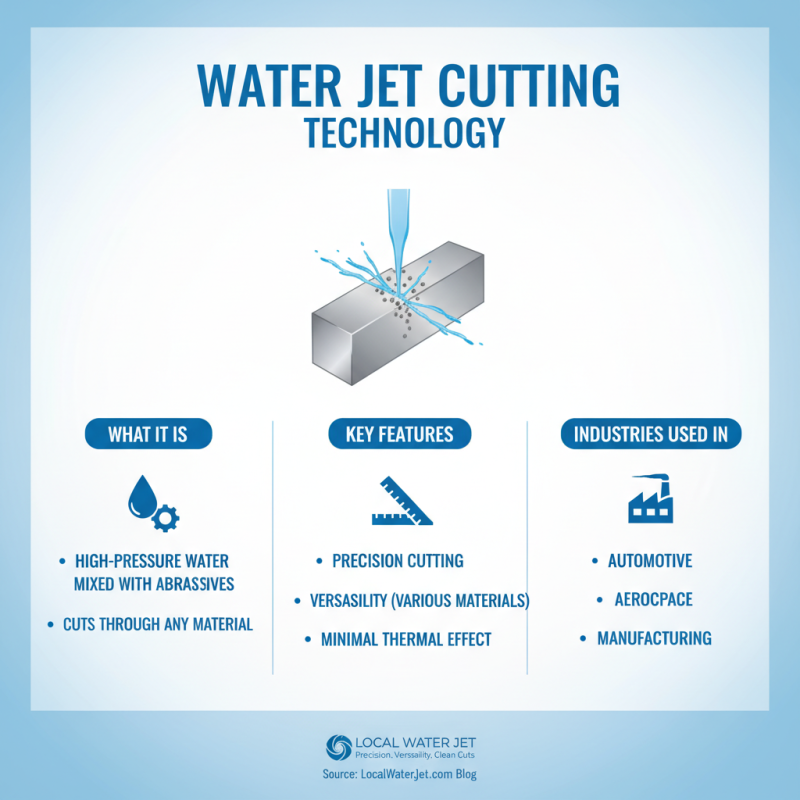

What is Local Water Jet Cutting and How Does It Work?

Local water jet cutting has emerged as a revolutionary technology in various industries, offering precision and versatility. According to a report by MarketsandMarkets, the global water jet cutting market is expected to reach $1.3 billion by 2027, driven by increased demand in manufacturing and automotive sectors. This innovative method utilizes high-pressure water to cut materials, minimizing thermal distortion often caused by traditional cutting techniques.

Expert Mark Foster, a leading figure in the local water jet cutting industry, stated, "The ability to cut different materials without altering their properties makes water jet cutting indispensable." This technology allows for intricate designs and cleaner edges, attracting industries from aerospace to construction. However, challenges remain. Maintenance costs and the need for skilled operators can hinder its adoption. Moreover, there is a growing concern about water usage.

As the industry evolves, it's clear that local water jet cutting is not just a trend; it's a necessity. The balance between efficiency and sustainability will define its future. This technology illustrates how innovation can meet the demands of modern manufacturing while prompting critical discussions about environmental impact.

What is Local Water Jet Cutting?

Local water jet cutting is a fascinating technology. It's widely used in various industries for its precision and versatility. This method cuts through materials using a high-pressure jet of water mixed with abrasive particles. The result is a clean cut with minimal thermal effect on the material.

What sets local water jet cutting apart is its adaptability. It can handle materials like metal, glass, and stone. This versatility makes it a go-to option in manufacturing and construction. However, not all water jet systems are created equal. Some may have limitations in cutting thickness or material types.

Operators must pay close attention to machine settings. An improper setup can lead to rough edges or incomplete cuts. This requires constant learning and adjustment. The process can be complex, but it is rewarding when executed correctly. Understanding the nuances of local water jet cutting can lead to better outcomes. There’s always room for improvement in mastering this cutting-edge technology.

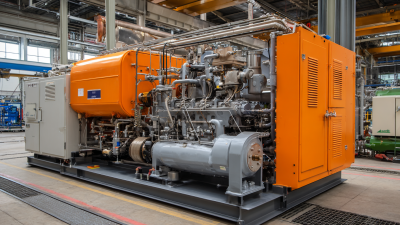

The Mechanism Behind Water Jet Cutting Technology

Water jet cutting is a fascinating technology. It uses a high-pressure jet of water to slice through various materials. This method is popular because it is precise and flexible. The machine operates by forcing water through a small orifice, creating an intense stream. Adding an abrasive material enhances its cutting ability. This allows it to work on tougher materials like metal or stone.

The mechanism behind water jet cutting involves several components. A high-pressure pump generates thousands of pounds of force. This pressure propels water at incredible speeds. The water then exits through a focused nozzle, which narrows the jet. This design creates a sharp, concentrated stream. When the jet hits a surface, it erodes the material with precision. However, achieving optimal results can require adjustments and experimentation. The angle, speed, and pressure must be fine-tuned for different materials.

Even though this technology is advanced, it is not free from challenges. Operators must understand the characteristics of the material being cut. Not all materials respond the same way. For instance, softer materials may require different techniques than harder ones. There is a learning curve involved. Miscalculations can lead to rough edges or incomplete cuts. This highlights the importance of experience and technique in water jet cutting. Achieving perfection is a continuous journey.

Water Jet Cutting Technology Performance Analysis

Applications of Local Water Jet Cutting in Various Industries

Local water jet cutting is gaining popularity across various industries. This technology employs a high-pressure water stream to cut through materials. Its applications are diverse and impactful.

In the manufacturing sector, local water jet cutting is used for precision cutting of metals and plastics. This method allows for intricate shapes without altering the material's properties. Additionally, the food industry utilizes water jet cutting to slice through delicate items like cakes and vegetables. This method ensures cleanliness and retains flavors, making it ideal for food preparation.

Moreover, the construction industry benefits from this technology as well. Water jet cutting can effortlessly shape stone and tiles, reducing waste. However, the process can be slow and requires skilled operators for optimal results. There are challenges to consider, such as maintenance costs and water usage. These factors require careful planning and reflection when integrating this cutting method into production lines.

Advantages of Using Local Water Jet Cutting Over Traditional Methods

Local water jet cutting is gaining traction in various industries. This method employs high-pressure water streams mixed with abrasive materials to slice through different materials. Compared to traditional cutting methods like laser or plasma cutting, water jet cutting offers a few clear advantages.

One notable advantage is its versatility. Water jet cutting can handle materials ranging from metal to glass and even rubber. Industry reports indicate that water jet cutting can reduce waste by up to 30%. This improvement is significant because it maintains material integrity, unlike traditional methods that may compromise surface quality.

When considering water jet cutting for a project, it's essential to evaluate the specific requirements. For delicate materials, water jet cutting minimizes thermal stresses. However, be aware that it might not be the fastest option available. The speed of cutting can vary based on material thickness.

Tips: Always assess your project's needs. Test different abrasive materials to optimize results. Additionally, ensure proper maintenance of your water jet machine. Regular checks can prevent unforeseen breakdowns and enhance precision. Balancing quality and efficiency is crucial. Not every project suits water jet cutting perfectly, so careful consideration is necessary.

Maintenance and Safety Considerations for Water Jet Cutting Systems

Water jet cutting systems require careful maintenance to ensure optimal performance. Regular inspections are critical. According to industry reports, about 30% of water jet system failures are due to lack of maintenance. Components such as nozzles and pumps must be checked frequently. A worn-out nozzle can lead to a decrease in cutting quality. It may even result in costly downtime.

Safety is another key consideration in water jet cutting operations. High-pressure water jets can be hazardous. Operators should always wear proper protective gear. This includes goggles and gloves. In some studies, 15% of injuries in fabrication can be attributed to improper safety measures in water jet cutting. Therefore, training for operators is essential. Understanding the machine’s features and limitations is vital. Well-trained staff can significantly reduce accident risks.

Moreover, the work environment plays a role in safety. Ensuring a clean workspace can prevent accidents. Cluttered areas increase the chance of slips and falls. It's worth noting that 20% of safety incidents stem from workplace issues. Regular safety audits can help identify risks. If safety protocols are ignored, the consequences can be severe. Balancing maintenance and safety is crucial for effective operation.

Related Posts

-

Maximize Precision and Efficiency with Local Water Jet Cutting: The Future of Material Processing

-

Exploring the Benefits of Water Jet Cutting for Precision Stainless Steel Fabrication

-

How to Use Water Jet Cutting for Steel: A Complete Guide

-

Top Benefits of Local Water Jet Cutting for Precision Manufacturing?

-

Best Water Jet Cutting Machines for Precision Cutting?

-

Understanding the Benefits of Water Jet Cutting Machines in Modern Manufacturing