What is a Jet Cutting Machine and How Does it Work?

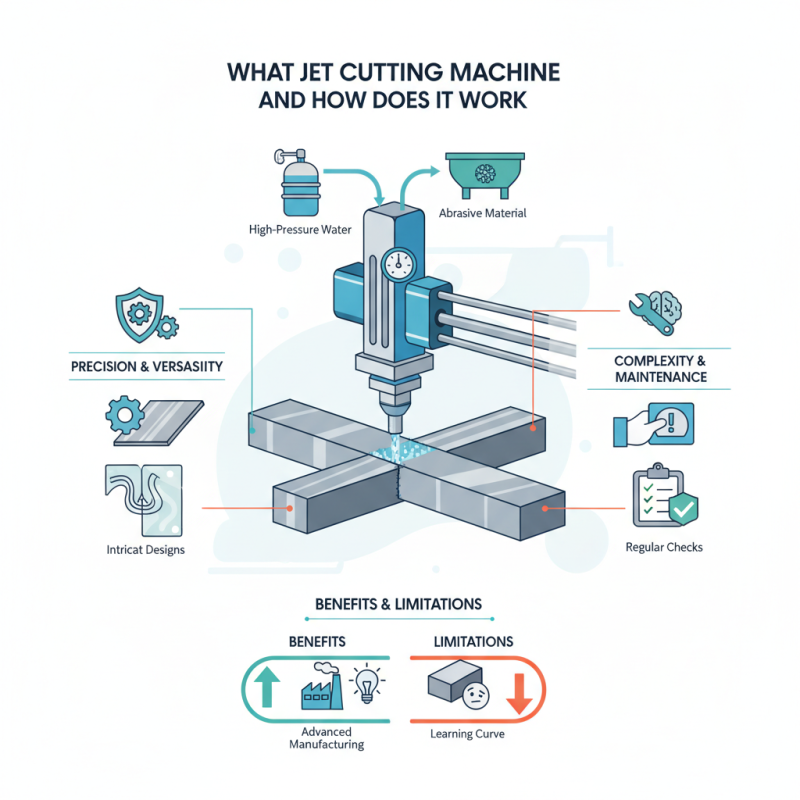

In the world of advanced manufacturing, the jet cutting machine stands out as a transformative technology. John Smith, a well-known expert in industrial fabrication, notes, "Jet cutting machines redefine precision in cutting processes." This innovative equipment utilizes high-pressure water jets or abrasive materials to slice through various materials, from metals to glass. The versatility of these machines allows for intricate designs that are challenging to achieve with traditional methods.

While the benefits are clear, the operation of a jet cutting machine is complex. Engineers must carefully calibrate pressure settings and material feed rates. Mistakes in these areas can lead to wasted resources and subpar cuts. Moreover, maintenance is critical for optimal performance. Regular checks help prevent costly downtimes and failures.

It's worth mentioning that despite their effectiveness, jet cutting machines have limitations. They may not be suitable for very thick materials or specific alloys. Users often face a learning curve, making initial phases frustrating. Yet, as users adapt, the potential for creative applications grows, making this technology indispensable in various industries.

What is a Jet Cutting Machine?

A jet cutting machine is a powerful tool used for cutting materials. It employs high-pressure water, often mixed with abrasive materials, to achieve precise cuts. The process involves directing a concentrated water jet through a nozzle. This creates an incredibly fast and focused stream. The result is a clean and accurate cut, whether in metals, ceramics, or soft materials.

These machines are versatile. They can handle various thicknesses and types of materials. However, operating a jet cutting machine requires skill. Misalignment can lead to uneven cuts. Moreover, the maintenance of the machine can be a challenge. The nozzle wears out over time, affecting performance. Regular checks are necessary to ensure optimal functioning.

The applications are diverse, ranging from aerospace to arts. However, not every job may be suited for this technology. Sometimes, other cutting methods may be more efficient. It's essential to weigh options based on project requirements. Jet cutting offers precision, but also has its limits. Consider all factors before choosing this method for your project.

Water Jet Cutting Machine Performance Comparison

Principles of Operation for Jet Cutting Machines

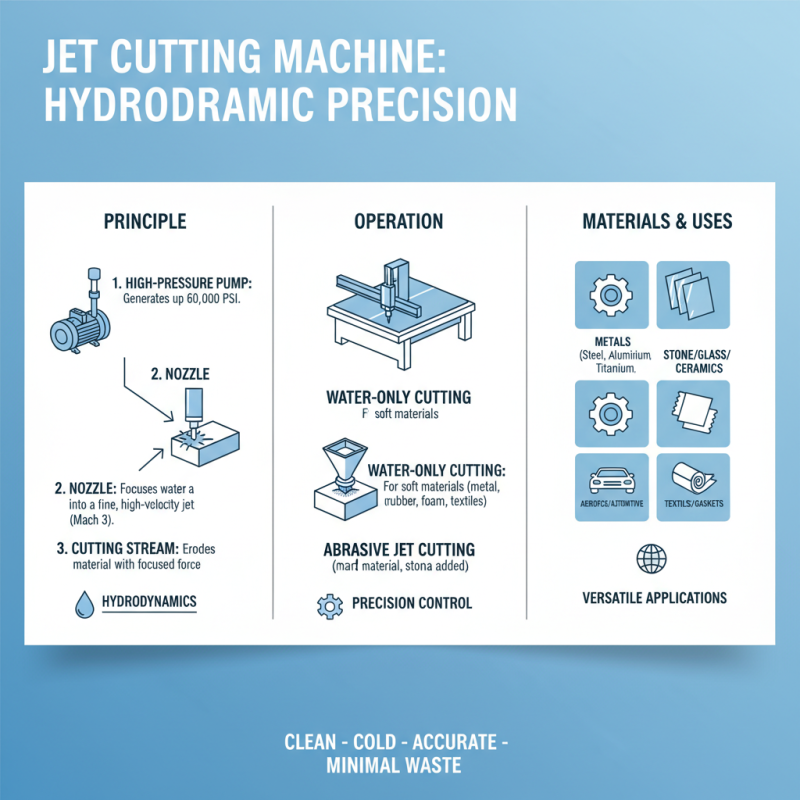

Jet cutting machines are innovative tools that use highly pressurized water or abrasive mixtures to cut through various materials. The core principle of operation is based on hydrodynamics. A pump generates extreme pressure, sending water through a small nozzle at high velocity. This creates a narrow, focused jet that can pierce hard materials.

The cutting process is fascinating. When the water jet strikes the surface, it erodes the material away. The effectiveness of the cut depends on the pressure and the type of abrasive added. Sometimes, however, the choice of materials can lead to unsatisfactory results. For example, softer materials can deform instead of cutting cleanly. Additionally, if the pressure isn't optimal, the cut may be uneven.

Operators must pay attention to key factors. The nozzle's diameter affects the cutting precision. A wider nozzle can be faster but less accurate. Conversely, a narrow jet requires more time but yields finer results. This balancing act often requires experimentation. Challenges may arise, and reflections on past cuts can lead to better outcomes in future projects.

Types of Jet Cutting Technologies Available

Jet cutting technologies are revolutionizing the manufacturing industry. They use high-pressure water jets to cut various materials. Among the most common jet cutting technologies are water jet cutting, abrasive water jet cutting, and pure water jet cutting. Each type serves different purposes depending on the materials involved.

Water jet cutting relies on high-pressure water to make precise cuts. It is ideal for soft materials like rubber or foam. An industry report suggests that water jet cutting accounts for around 35% of the global cutting technology market. Abrasive water jet cutting adds a mixture of abrasive materials to the water, enabling it to slice through hard materials like metal and stone. This method has gained traction, as the demand for intricate designs in tough materials has surged.

Pure water jet cutting uses just water. It is suitable for soft materials but less versatile. Limitations arise when attempting to cut thicker materials. As technology progresses, the efficiencies of jet cutting remain a growing area of interest. Industrial players must adapt to advances. Continuous improvement in jet cutting technology can enhance accuracy and minimize waste. However, balancing cost-effectiveness and quality is a challenge. The future of jet cutting lies in innovation and sustainability.

Applications of Jet Cutting Machines in Various Industries

Jet cutting machines are versatile tools widely used in various industries. They utilize high-pressure water jets or abrasive mixtures to cut through materials. This technology allows for precision and minimizes material wastage. It's fascinating how a simple water jet can slice through thick steel or delicate fabrics.

In the automotive sector, jet cutting machines play a critical role. They help shape parts without causing thermal distortion. This is vital for maintaining tight tolerances. Similarly, in aerospace, they are used to create complex components from tough materials. However, the process isn’t flawless. Sometimes, operators face challenges with machine calibration and inconsistent cutting speeds.

The construction industry also benefits from this technology. Jet cutting is used for creating intricate designs in stone and concrete. It provides aesthetic value while ensuring structural integrity. Yet, the initial setup can be time-consuming. Operators must be skilled to avoid costly mistakes. This shows that while jet cutting machines have great potential, there’s always room for improvement.

Advantages and Limitations of Using Jet Cutting Machines

Jet cutting machines have gained popularity in various industries. They offer advantages such as

precision and versatility. The ability to cut a wide range of materials, including metals and ceramics, is a significant

benefit. According to recent industry reports, water jet cutting can achieve tolerances of

±0.005 inches. This precision minimizes waste and optimizes material usage.

However, using jet cutting machines also comes with limitations. The initial setup cost can be high.

Maintenance requires skilled technicians, which adds to operational expenses. Additionally, while water jet cutting is effective for many materials,

it struggles with hard materials like tempered glass. The reliance on high-pressure water streams can also lead to overspray, creating mess and requiring further cleanup.

As industries adopt this technology, more may need to weigh the costs against the benefits. Innovation is ongoing, yet challenges remain.

The industry must address efficiency concerns and refine processes. This balance is crucial for further growth in the use of jet cutting machines.

Related Posts

-

Unlocking Precision: How Water Jet Cutting Systems Revolutionize Metal Fabrication with 0.005-Inch Accuracy

-

What is a Jet Cutting Machine and How Does It Work in Manufacturing

-

The Ultimate Guide to Understanding How a Water Jet Head Transforms Industrial Cutting

-

2025 Top 5 Water Jet Cutting Accuracy Innovations for Precision Manufacturing

-

How to Use Water Jet Cutting for Steel: A Complete Guide

-

2026 Top Trends in Waterjet Cutting Aluminum Techniques?