The Future of Precision Manufacturing with Waterjet Cutting Technology in Utah

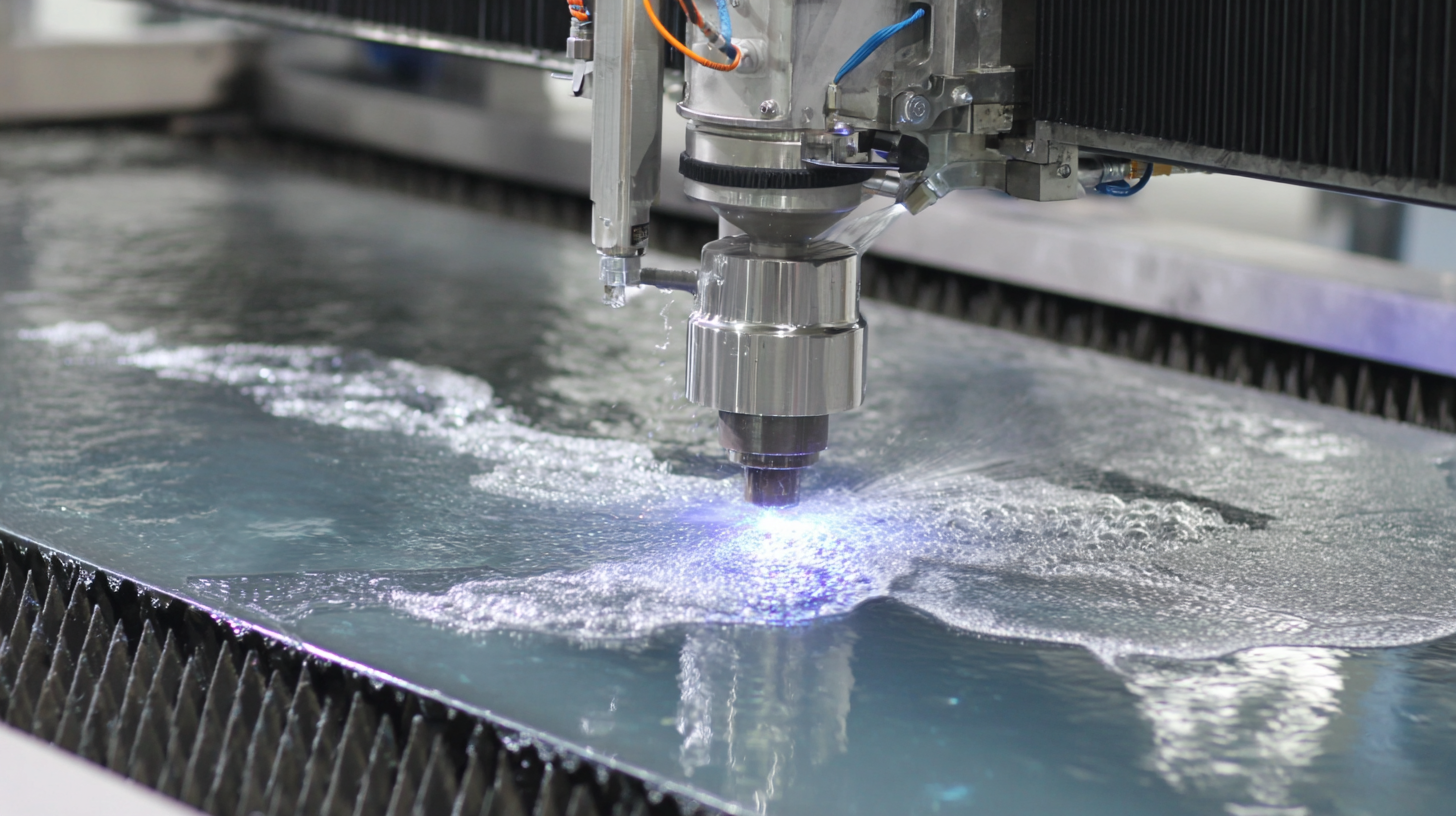

In the realm of modern manufacturing, precision and efficiency have become paramount, and no technology embodies these principles better than waterjet cutting. Waterjet cutting technology in Utah has emerged as a game changer, revolutionizing how industries approach material processing and fabrication. Utilizing high-pressure water streams mixed with abrasives, this method allows for intricate cuts on a wide range of materials, from metals to composites, without the heat-affected zones typical of traditional cutting methods. As we explore the future of precision manufacturing in Utah, understanding the capabilities and advantages of waterjet cutting will be crucial for businesses aiming to maintain competitiveness in an ever-evolving market. This guide aims to provide insights into the practical applications, benefits, and advancements in waterjet cutting technology, empowering manufacturers to harness its full potential.

Exploring the Basics of Waterjet Cutting Technology in Precision Manufacturing

Waterjet cutting technology has emerged as a game-changer in the realm of precision manufacturing, particularly in Utah, where industries are rapidly adopting this innovative method. Utilizing high-pressure water mixed with abrasive materials, this technique allows for the cutting of a wide variety of materials, including metals, ceramics, and plastics, with extraordinary accuracy. The ability to produce intricate designs without the heat-affected zones that conventional cutting methods may cause makes waterjet cutting ideal for maintaining the integrity of sensitive components.

Waterjet cutting technology has emerged as a game-changer in the realm of precision manufacturing, particularly in Utah, where industries are rapidly adopting this innovative method. Utilizing high-pressure water mixed with abrasive materials, this technique allows for the cutting of a wide variety of materials, including metals, ceramics, and plastics, with extraordinary accuracy. The ability to produce intricate designs without the heat-affected zones that conventional cutting methods may cause makes waterjet cutting ideal for maintaining the integrity of sensitive components.

Tips for Effective Waterjet Cutting:

- Material Selection: Choose the right type of material based on your project requirements. Consider the unique properties and thickness of the material to enhance cutting efficiency.

- Maintenance Matters: Regular maintenance of the waterjet cutting equipment ensures optimal performance and longevity. Check for wear and tear on components to avoid costly downtimes.

As businesses in Utah explore the potential of waterjet cutting, it is crucial to stay informed about the latest advancements and best practices. By integrating this technology into their manufacturing processes, companies can achieve unprecedented levels of precision and efficiency, ultimately driving innovation and growth in the industry.

Key Advantages of Waterjet Cutting in Modern Manufacturing Processes

Waterjet cutting technology is revolutionizing precision manufacturing in Utah, providing distinct advantages that enhance modern manufacturing processes. One of the key benefits is its versatility; waterjet cutting can work with a wide range of materials, including metals, ceramics, and composites. This adaptability allows manufacturers to take on diverse projects without needing to change equipment, reducing downtime and increasing overall efficiency. Additionally, the cold cutting process ensures that materials maintain their structural integrity, preventing thermal distortion often associated with traditional cutting methods.

Tip: When considering integrating waterjet cutting into your production line, assess the compatibility of the technology with your materials. Knowing which materials yield the best results can streamline operations and improve quality.

Another significant advantage of waterjet cutting is its precision. The technology can achieve tolerances as tight as ±0.005 inches, making it ideal for industries that require meticulous detail such as aerospace and automotive. This high degree of accuracy not only minimizes waste but also decreases the need for extensive post-processing, allowing manufacturers to accelerate their production timelines.

Tip: Regular maintenance of waterjet cutting equipment is crucial for sustained accuracy and efficiency. Schedule routine checks to ensure optimal performance and longevity of your machines.

Application of Waterjet Cutting Across Various Industries in Utah

Waterjet cutting technology is making significant advancements across various industries in Utah, highlighting its versatility and efficiency. This innovative method utilizes high-pressure water streams to cut through materials with precision, making it an ideal solution for applications in industries ranging from aerospace to architecture. For instance, the recent expansion of fabrication operations in Ogden illustrates how businesses are harnessing cutting-edge technology to enhance production capabilities and meet growing demand.

Moreover, the emergence of novel applications, such as the transformation of glass from transparent to opaque with a simple switch, showcases the potential of waterjet cutting in creating functional yet aesthetically pleasing products. These advancements not only improve product offerings but also contribute to workplace safety and security. As Utah continues to embrace precision manufacturing, the role of waterjet cutting technology will undoubtedly grow, paving the way for innovative solutions across various sectors and fostering economic development within the region.

Implementing Waterjet Cutting Technology: Steps for Manufacturers

Implementing waterjet cutting technology in Utah's manufacturing sector requires careful planning and execution. According to a report by the International Journal of Advanced Manufacturing Technology, the adoption of waterjet cutting can enhance precision by up to 75% compared to traditional techniques. This level of accuracy is crucial for industries ranging from aerospace to automotive, where even minor deviations can lead to significant production issues. Manufacturers should begin by assessing their current capabilities and identifying how waterjet cutting can meet their specific needs.

One vital tip for manufacturers is to invest in training for their workforce. A skilled operator can maximize the efficiency of waterjet systems, optimizing cutting speeds and tool wear while minimizing material waste. According to the Manufacturing Institute, companies that prioritize employee training see a 25% increase in productivity on average. Furthermore, creating a structured implementation plan that includes sourcing high-quality equipment and maintaining regular maintenance schedules is essential for long-term success.

Additionally, manufacturers should consider forming partnerships with local tech firms that specialize in waterjet technology. Collaborating with experts can provide insights into best practices and innovation trends in the sector. A study by the Boston Consulting Group emphasizes that companies engaging in such partnerships report a 30% improvement in their operational efficiency. By following these steps, Utah manufacturers can effectively integrate waterjet cutting technology into their processes and remain competitive in the evolving market.

The Future of Precision Manufacturing with Waterjet Cutting Technology in Utah

| Dimension | Value |

|---|---|

| Average Waterjet Cutting Speed (in/min) | 30 - 100 |

| Material Types Processed | Metal, Glass, Stone, Composites |

| Typical Thickness Range | 0.01 - 12 inches |

| Waterjet Technology Adoption Rate (Utah) | 25% |

| Cost Savings Per Project | 15 - 30% |

| Lead Time Reduction | 20-50% |

| Employee Training Time for New Technology | 2-4 weeks |

| Environmental Benefits | Less Waste & Energy Efficient |

Future Trends in Precision Manufacturing with Waterjet Innovations

The landscape of precision manufacturing is undergoing significant transformation, with waterjet cutting technology leading this evolution. According to a report by MarketsandMarkets, the global waterjet cutting market is projected to reach USD 1.9 billion by 2025, growing at a CAGR of 6.6% from 2020. This growth is fuelled by the technology's ability to deliver high precision while minimizing material waste, making it an attractive option for industries ranging from aerospace to automotive.

Innovations in waterjet technology are set to enhance the efficacy of precision manufacturing further. Advanced control systems and multi-axis cutting capabilities are revolutionizing the way manufacturers approach complex design challenges. A study by Research and Markets indicates that the demand for waterjet systems equipped with automation technologies is surging, with automation expected to capture over 30% of the market share by 2027. In Utah, local manufacturers are already leveraging these innovations, not only to improve accuracy but also to reduce production costs and lead times, setting a benchmark for the future of precision manufacturing in the region.

The Future of Precision Manufacturing with Waterjet Cutting Technology in Utah

This bar chart illustrates the projected growth rate of precision manufacturing with waterjet cutting technology in Utah over five years, indicating a positive trend in market adoption and innovation.