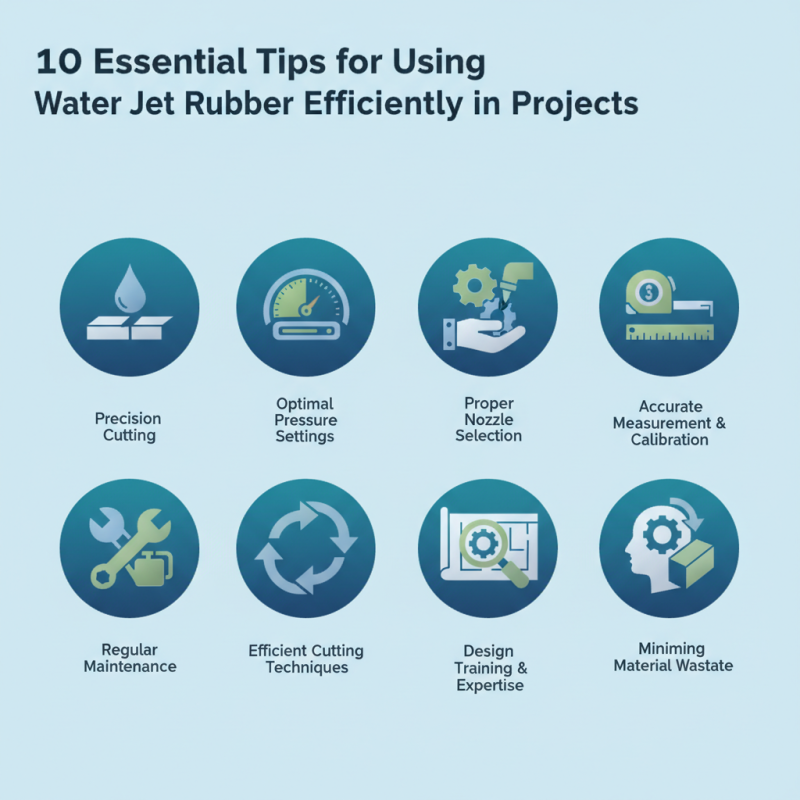

10 Essential Tips for Using Water Jet Rubber Efficiently in Projects

Water jet rubber is becoming increasingly crucial in various industries. According to a recent report by Research and Markets, the global water jet cutting market is expected to reach $4.68 billion by 2025, growing at a CAGR of 7.7%. This growth reflects the importance of efficient materials like water jet rubber in enhancing productivity and precision.

When properly utilized, water jet rubber can significantly improve project outcomes. Its unique properties allow for clean cuts and minimal material wastage. Yet, many professionals still struggle with its effective application. Misuse or inadequate understanding can lead to inefficiencies and costly errors. For instance, using improper pressure settings can compromise both the material and the final product quality.

Investing time to learn the nuances of water jet rubber is essential. Understanding how to adjust settings, techniques, and maintenance can elevate work quality. Many overlook these considerations, resulting in lost time and resources. Emphasizing training and mastery can transform standard practices into cutting-edge solutions.

Understanding Water Jet Rubber and Its Applications

Water jet rubber technology provides unique solutions in various industries. This material is commonly used in cutting applications due to its flexibility and resistance to wear. According to a recent report by the International Journal of Advanced Manufacturing Technology, water jet rubber can enhance precision cutting by up to 30%. This significant improvement allows manufacturers to reduce material waste.

When using water jet rubber, it’s crucial to understand its properties. The thickness and density of the rubber can affect the cutting quality. Using the right level of water pressure is also essential. Too high pressure can damage the rubber, while too low may produce subpar results. Always conduct test cuts to determine the optimal settings for your specific project.

Tip: Keep your workspace clean. Dust and debris can affect the cutting process and lead to inaccuracies. A tidy environment helps achieve better results.

Water jet rubber is versatile but requires a careful approach. Mistakes, such as using incorrect materials, can lead to project delays. Data from industry reports indicates that improper use can increase costs by 15%. Evaluate your methods regularly to improve efficiency and outcomes. The more you learn, the better your results will be.

Water Jet Rubber Efficiency in Various Projects

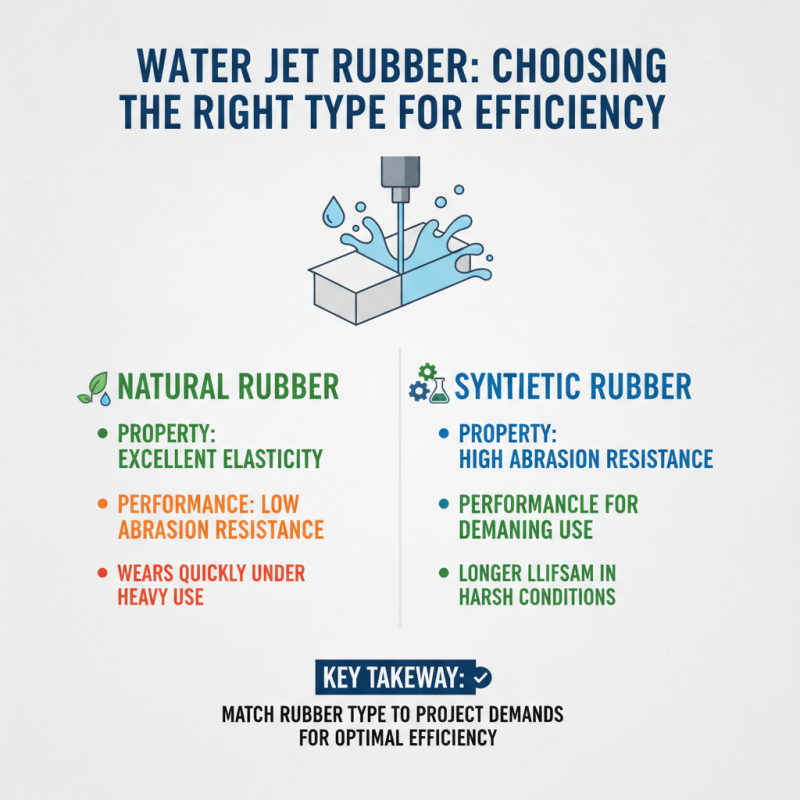

Choosing the Right Type of Water Jet Rubber for Your Project

Choosing the right type of water jet rubber is crucial for project efficiency. Different rubber types exhibit varied performance based on their properties. For instance, natural rubber typically offers excellent elasticity but wears out quickly under heavy use. Synthetic options often provide higher abrasion resistance, making them suitable for more demanding applications.

In a study published by the American Society of Mechanical Engineers, it was shown that projects utilizing high-performance rubber can reduce waste by up to 30%. This is significant. However, some firms still opt for lower-cost alternatives, leading to premature failures. Their choice may seem economical initially, but in the long term, it often proves costly.

Also, it’s vital to consider the thickness of the rubber sheets. Thicker sheets can withstand higher pressures, but they may also be more cumbersome to handle. Striking a balance between durability and ease of use is necessary yet often overlooked by new users. Proper evaluation of your project's specific needs will aid in selecting the most suitable water jet rubber. This decision directly impacts overall project performance and cost efficiency.

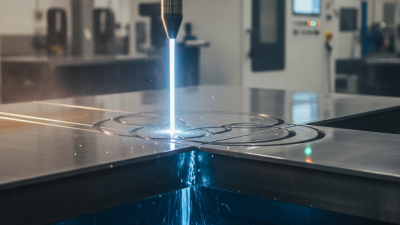

Techniques for Efficiently Cutting Materials with Water Jet Rubber

Water jet rubber cutting offers remarkable precision and efficiency. This technique uses high-pressure water mixed with abrasive materials to cut through various materials. According to a recent industry report, this method reduces material wastage by around 30%. The precision of water jet cutting minimizes the need for additional finishing processes, saving both time and cost.

To maximize efficiency, consider nozzle selection carefully. Different nozzles can significantly affect cutting speed and accuracy. A poorly chosen nozzle might decrease performance. Manufacturers estimate that proper nozzle choice can enhance cutting speed by up to 25%. Regular maintenance of the equipment cannot be overlooked, either. Neglect can lead to reduced performance and increased downtime.

Additionally, aligning the material correctly is crucial. Misalignment may lead to uneven cuts. This could result in higher costs due to wasted materials. An optimal cutting speed is essential, too. If too fast, quality suffers. If too slow, production efficiency drops. Reflection on these factors can vastly improve outcomes in any project involving water jet rubber cutting.

Maintaining Water Jet Rubber for Optimal Performance

Maintaining water jet rubber is crucial for efficient performance. According to industry reports, regular maintenance can increase the lifespan of rubber by up to 30%. Water jet rubber can wear out quickly if not properly cared for.

One essential tip is regular inspection. Check for wear and tear before every project. Look for cracks and other damage. These can affect water flow and project accuracy. Small damages can lead to bigger issues if neglected.

Another important aspect is cleaning. After each use, rinse the rubber with clean water. This helps remove abrasive particles that can cause deterioration. Keeping the rubber clean preserves its integrity.

Monitor operating pressures as well. High pressures can lead to excessive wear. Industry standards suggest keeping pressures within recommended limits. Following these tips can help you optimize your water jet rubber's performance.

Safety Precautions When Using Water Jet Rubber in Projects

When using water jet rubber in projects, safety precautions are paramount. Always wear protective gear, including goggles and gloves. This will shield you from splashes and debris. Rubber can create unexpected reactions under pressure. A sudden burst might cause injuries. Therefore, inspect your setup before starting.

Ensure your workspace is clean. Clutter can lead to slip hazards. Keep everything organized. This might seem minor, but a tidy area is crucial. Don’t rush through setup. Take your time to secure materials properly. In a hurry, you might forget something important. Remember, safety should never be compromised.

Educate yourself about possible risks. Every project is different. Understanding the specific dangers of water jetting rubber can save you from accidents. Always have a first aid kit nearby. Accidents can happen, and it’s better to be prepared. Regularly review safety procedures with your team. This reinforces a culture of safety. Your well-being is the top priority.

Related Posts

-

Water Jet Fabrication Tips for Efficient and Precise Cutting?

-

Maximize Precision and Efficiency with Local Water Jet Cutting: The Future of Material Processing

-

The Future of Cutting Technologies Exploring the Benefits of Water Jet Abrasive Systems

-

Exploring the Benefits of Water Jet Cutting for Precision Stainless Steel Fabrication

-

Understanding the Benefits of Water Jet Cutting Machines in Modern Manufacturing

-

The Ultimate Guide to Understanding How a Water Jet Head Transforms Industrial Cutting