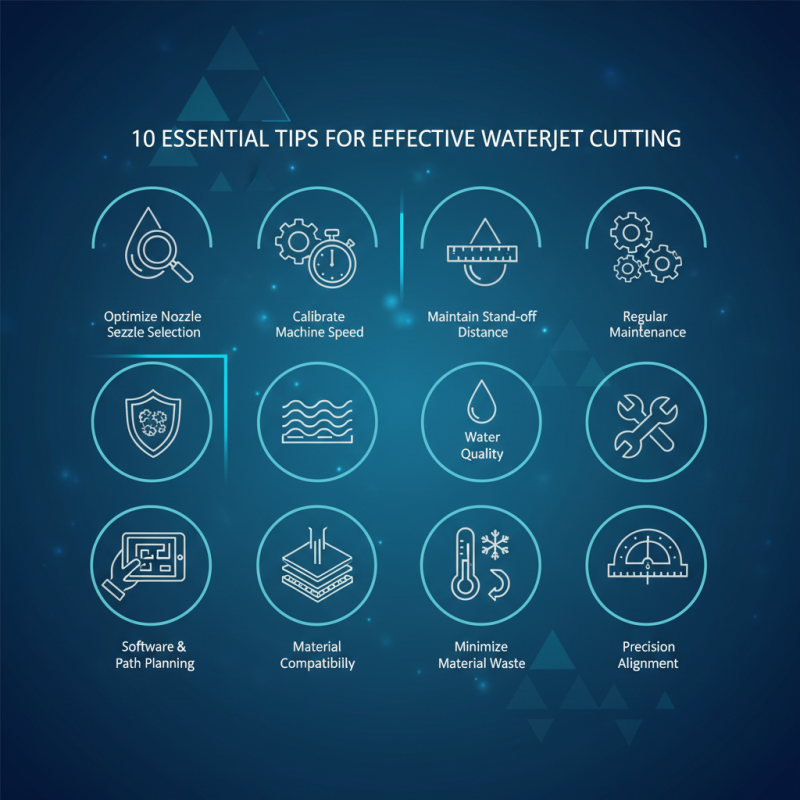

10 Essential Tips for Effective Waterjet Cutting: Maximize Precision and Efficiency

Waterjet cutting has emerged as a crucial technology in various manufacturing sectors, delivering unparalleled precision and efficiency in material processing. According to a report from industry analysts, the global waterjet cutting market is projected to reach USD 1.15 billion by 2026, reflecting a compound annual growth rate (CAGR) of 7.5% from 2021. This growth is driven by the increasing demand for advanced machining solutions that can handle a wide range of materials, including metals, ceramics, and composites, without altering their intrinsic properties. The versatility of waterjet cutting not only reduces the margin of error but also minimizes waste, contributing to more sustainable manufacturing practices.

As industries strive to enhance productivity while maintaining quality, optimizing waterjet cutting operations becomes imperative. Technical advancements and innovations have significantly improved the capabilities of waterjet systems, allowing for intricate designs and tighter tolerances. Reports indicate that when properly calibrated, waterjet cutting can achieve tolerances as tight as ±0.005 inches, reinforcing its value in precision-critical applications such as aerospace, automotive, and medical manufacturing. By focusing on essential practices in waterjet cutting, businesses can maximize their operational efficiency and maintain a competitive edge in an increasingly demanding marketplace.

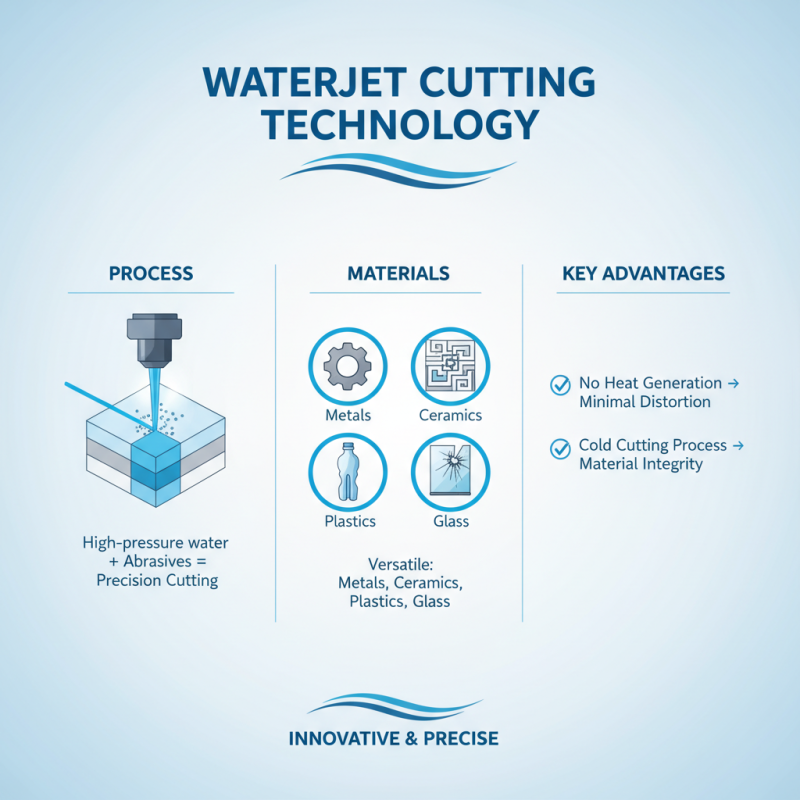

Understanding the Basics of Waterjet Cutting Technology

Waterjet cutting technology is an innovative machining process that utilizes a high-pressure stream of water, often mixed with abrasives, to cut through various materials with remarkable precision. This technique is versatile, capable of handling materials ranging from metals and ceramics to plastics and glass. The fundamental principle behind waterjet cutting lies in the sheer force of water, which can slice through materials without generating heat, thus minimizing distortion and maintaining the integrity of the cut components.

Understanding the components of this cutting process is essential for maximizing its effectiveness. Key elements include the water source, intensifier pumps, and nozzle designs, which all play pivotal roles in determining the cutting speed and quality. The waterjet cutting process allows for intricate designs and can achieve tolerances that exceed those of traditional cutting methods. By mastering the setups and configurations, operators can enhance both productivity and efficiency, proving that knowledge of waterjet cutting fundamentals is crucial for any operation aiming to achieve superior results in material processing.

Choosing the Right Waterjet Cutting Equipment for Your Needs

When selecting the right waterjet cutting equipment for your needs, it's essential to consider several key factors that can significantly impact your project outcomes. Waterjet cutting technology utilizes high-pressure water streams, often mixed with abrasive materials, to achieve precise cuts in various materials, including metal, glass, and composites. According to a report by TechSci Research, the global waterjet cutting market is projected to reach USD 3 billion by 2025, highlighting the growing demand for these versatile machines across industries like aerospace, automotive, and manufacturing.

Choosing the right equipment starts with understanding the type of materials you'll be working with and the thicknesses involved. For instance, lighter materials can be efficiently cut with pure waterjet systems, while thicker and more challenging materials may require an abrasive waterjet system for optimal performance. Furthermore, considering factors such as pump power, cutting head configuration, and control software can enhance precision. A study by Market Research Future indicates that advancements in CNC technology for waterjet cutting enhances operational efficiency and reduces production time, making it crucial to invest in up-to-date equipment that meets modern industrial standards. By aligning your equipment choice with your specific cutting requirements, you can maximize both precision and efficiency in your waterjet cutting projects.

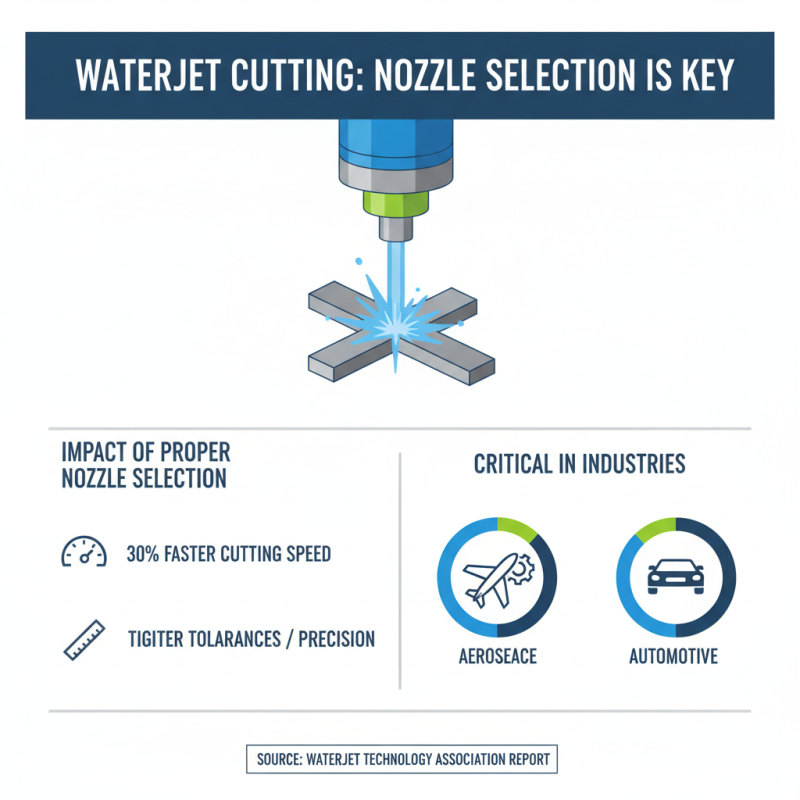

Maintaining Precision: Importance of Proper Nozzle Selection

The choice of nozzle is paramount in waterjet cutting, as it directly impacts both the precision of the cut and the overall efficiency of the operation. According to a report by the Waterjet Technology Association, proper nozzle selection can improve cutting speed by up to 30%, while ensuring that tolerances remain within tight specifications. This is critical in industries such as aerospace and automotive, where even minute deviations can lead to substantial operational issues and increased costs.

Moreover, the material being processed plays a significant role in nozzle selection. Different materials require different types of nozzles to achieve optimal results. A recent study indicated that using the correct nozzle size and shape can enhance kerf quality and reduce the incidence of edge tapering, ultimately leading to a smoother finish. Additionally, effective nozzle maintenance is crucial; clogged or worn nozzles can result in inconsistent cuts and unnecessary waste. Hence, understanding the interplay between nozzle selection and maintenance is essential for maximizing cut quality and operational efficiency in waterjet cutting applications.

Optimizing Cutting Speed and Pressure Settings for Efficiency

When optimizing cutting speed and pressure settings in waterjet cutting, it is crucial to find a balance that maximizes efficiency while maintaining precision. Higher cutting speeds generally lead to faster processing times; however, pushing the speed too high can compromise the quality of the cut. By incrementally adjusting the speed and monitoring the resulting cut quality, operators can identify the optimal settings for specific materials. Moreover, factors such as material thickness and type significantly influence the ideal speed, making it essential to tailor settings for each new job.

Pressure settings also play a vital role in the efficiency of waterjet cutting. Higher pressure can enhance cutting performance by allowing the jet to penetrate tougher materials more effectively. However, excessive pressure can lead to increased wear on the cutting nozzle and can produce more abrasive sludge, which may interfere with the cutting process. A careful examination of the material hardness and desired cut edge quality can guide the selection of optimal pressure levels. Regularly maintaining the waterjet system and running tests with different combinations of speed and pressure will help achieve consistent results and streamline the cutting process, ultimately leading to reduced operational costs and improved output.

10 Essential Tips for Effective Waterjet Cutting: Maximize Precision and Efficiency

| Tip | Description | Optimal Cutting Speed (IPM) | Recommended Pressure (psi) |

|---|---|---|---|

| 1. Material Selection | Choose the right material for the application to enhance efficiency. | 30 | 60000 |

| 2. Proper Nozzle Diameter | Select an appropriate nozzle size for the thickness of the material. | 20 | 55000 |

| 3. Adjusting Cutting Speed | Fine-tune the cutting speed based on the material's properties. | 40 | 65000 |

| 4. Maintain Water Quality | Ensure clean water to prevent damage to the cutting system. | 35 | 58000 |

| 5. Optimize Abrasive Material | Select the best abrasive for the material being cut. | 50 | 60000 |

| 6. Regular Maintenance | Schedule regular maintenance to keep the system in top condition. | -- | -- |

| 7. Use of Automation | Implement automation to reduce human error and increase productivity. | -- | -- |

| 8. Analyze Cutting Data | Collect and analyze data to fine-tune operations for optimal results. | -- | -- |

| 9. Software Optimization | Utilize advanced software to enhance cutting programs. | -- | -- |

| 10. Safety First | Ensure safety procedures are followed to protect personnel and equipment. | -- | -- |

Streamlining Workflow: Tips for Material Handling and Setup

When it comes to waterjet cutting, optimizing material handling and setup is crucial for ensuring precision and efficiency. A streamlined workflow begins with meticulous preparation of materials. Ensuring that the workpieces are clean, free from contaminants, and properly secured can significantly enhance cutting quality. Utilize appropriate fixtures or clamps to hold materials firmly in place, as this prevents any movement during the cutting process, leading to greater accuracy in the final product.

Additionally, effective layout planning can contribute to an efficient workflow. Consider the order of operations and the type of cuts required before positioning materials on the cutting table. Organizing the materials in a way that minimizes the travel distance for the cutting head not only saves time but also reduces wear on the machine. Implementing systematic labeling can further simplify the setup process, allowing operators to quickly identify materials and their corresponding setups.

By prioritizing thorough material handling and strategic setup, manufacturers can maximize the capabilities of waterjet cutting technology and achieve superior results.

Related Posts

-

Top Benefits of Waterjet Cutting for Your Manufacturing Needs

-

Understanding the Benefits of Jet Cut Technology in Modern Manufacturing

-

Top 10 Advantages of Using Waterjet Garnet for Precision Cutting in Industries

-

Why Choose Waterjet Cutting Services in Seattle for Your Precision Needs?

-

Why You Should Consider a Lift Dock for Your Waterfront Property

-

The Future of Precision Manufacturing with Waterjet Cutting Technology in Utah