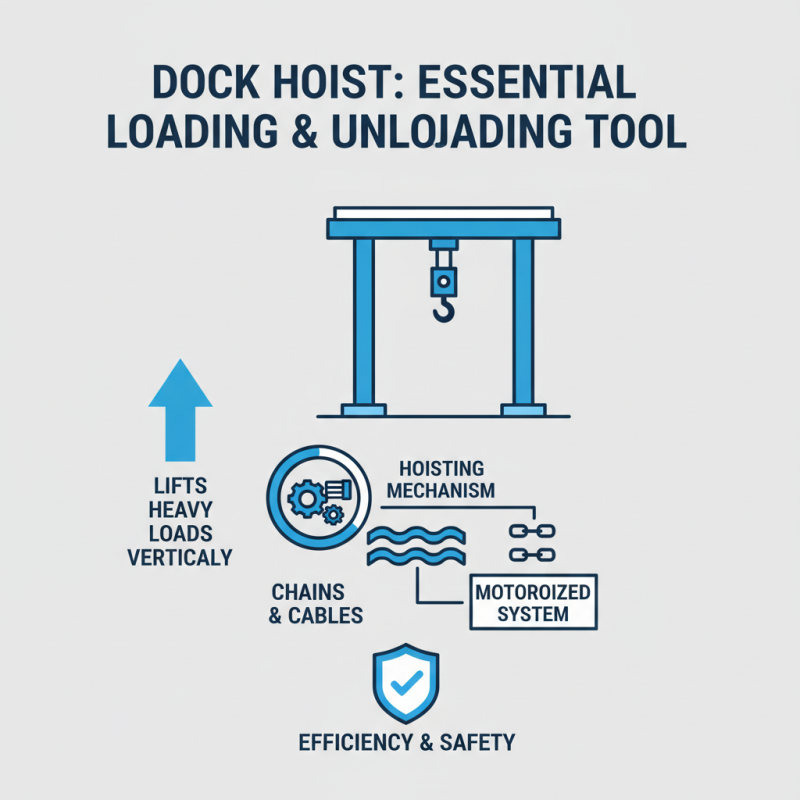

What is a Dock Hoist and How Does it Work?

A dock hoist is an essential piece of equipment in shipping and logistics. It helps lift heavy loads from trucks to storage areas. According to industry expert John Smith, "A dock hoist transforms workflow, ensuring efficiency and safety." This statement highlights its importance in the operational flow.

In a busy port, a dock hoist can significantly reduce handling time. Operators rely on this machine for loading and unloading goods. Its hydraulic system lifts cargo effortlessly, easing the burden on workers. However, not all dock hoists are created equal. Maintenance is crucial to avoid accidents and equipment failure. A poorly maintained dock hoist can lead to serious injuries.

While many companies invest in high-quality dock hoists, some overlook the significance of proper training. Workers must know the operational nuances to maximize safety. A dock hoist is more than just machinery; it represents a critical link in supply chains. Reflecting on this, occasional lapses in training and maintenance reveal areas in need of improvement.

What is a Dock Hoist?

A dock hoist is a crucial piece of equipment used in loading and unloading goods at docks. It serves to lift heavy items safely and efficiently. This machinery is designed to operate with a strong frame that can withstand substantial weight. The hoist usually connects to a lifting mechanism, often powered by electric motors or hydraulic systems.

Dock hoists are typically found on cargo ships, warehouses, or shipping docks. Their design includes a platform that elevates loads to the required height. Operators must follow strict safety guidelines. Neglecting these can lead to accidents. Regular maintenance is key to ensuring that the hoist functions correctly. Skipping inspections might result in costly repairs or injuries.

Although dock hoists are beneficial, they come with limitations. They require enough space for operation. Also, operators need training to manage them effectively. Misuse can lead to dangerous situations. It's important to recognize potential flaws in operation. Each instance can provide valuable lessons for improvement.

Dock Hoist Performance Metrics

This bar chart represents the performance metrics of a dock hoist. The three dimensions measured are Load Capacity, Operating Speed, and Hydraulic Pressure, which reflect the efficiency and capability of the dock hoist system.

Components of a Dock Hoist

A dock hoist is an essential tool in loading and unloading operations. Its main components work together to ensure efficiency and safety. The primary part is the hoisting mechanism. It lifts heavy loads vertically. Chains or cables connect to a motorized system that manages the height.

Next is the platform. This part provides a stable surface for items. It varies in size, depending on the application. The platform usually has safety edges to prevent loads from slipping off. Then, there are safety barriers. They protect users from falling during the operation. Regular inspection of these components is vital.

Another crucial component is the control system. This part allows operators to manage the hoist. Simple buttons or more complex controls can be used. However, faulty controls can lead to accidents. Operators must be trained. They often overlook their training, which can be concerning. It’s important to prioritize both safety and efficiency.

How a Dock Hoist Operates

A dock hoist is a mechanical device used for lifting heavy loads. It operates by utilizing a series of pulleys and hydraulic systems. When activated, the hoist engages powerful cables to raise or lower materials. This ensures safe and efficient transfer between a dock and a vessel.

Understanding how a dock hoist operates involves a closer look at its components. The platform is crucial; it provides a stable surface for the load. Operators usually control it using a simple joystick panel. That allows precise movements, even in crowded conditions. However, the setup can sometimes lead to accidents if not handled properly. Regular maintenance is needed to keep it running smoothly.

Despite its efficiency, there are some drawbacks. Training is required for operators to ensure safety. They must understand load limits and emergency procedures. Poor communication can lead to mistakes. It's essential to conduct regular drills to prepare for potential issues. Even with technology, human error remains a challenge. A conscious effort toward reflection and improvement is necessary.

Applications of Dock Hoists in Various Industries

Dock hoists play a vital role in several industries. They are often found in shipping, manufacturing, and construction. In the shipping industry, dock hoists facilitate the loading and unloading of cargo. According to a recent report, over 70% of freight shipping relies on efficient material handling systems. Dock hoists increase productivity by reducing the time it takes to transfer goods.

In construction, dock hoists are used to move heavy materials. They are crucial for transporting steel beams, concrete blocks, and tools. Safety is a concern, with nearly 10% of construction injuries occurring during material handling. Proper training and equipment maintenance are essential to minimize risks.

The manufacturing sector also benefits from dock hoists. They help streamline assembly lines and optimize factory workflows. A study indicated that companies using advanced dock hoists saw a 15% increase in efficiency. However, many facilities still struggle to implement best practices consistently. This inconsistency can lead to wasted resources and higher operational costs. Improving the training of operators and ensuring regular equipment checks are necessary for better performance.

Safety Considerations When Using a Dock Hoist

When operating a dock hoist, safety should be the top priority. A dock hoist is designed to lift heavy loads efficiently. However, improper use can lead to accidents. It's crucial to wear appropriate protective gear, such as gloves and safety shoes. Always be aware of your surroundings while using the hoist. Ensure the area is clear of obstacles.

Before using the dock hoist, conduct a thorough inspection. Check for wear or damage on the hoist cables and pulleys. Pay attention to any unusual sounds during operation. If something feels off, stop immediately.

Training is key. Everyone operating the hoist should understand how it works. Not knowing can create danger. Communication among team members is essential.

Establish clear signals or use walkie-talkies for coordination. Don't overload the hoist. Respect its weight limits.

Finally, remember to keep a safe distance from the load while lifting. Safety is not just a guideline—it’s a responsibility. Reflecting on these practices can enhance workplace safety significantly.

Related Posts

-

Unlocking Efficiency: How Dock Hoists Revolutionize Maritime Operations and Improve Safety

-

How to Choose the Right Dock Hoist for Your Industrial Needs

-

Top 10 Benefits of Using a Dock Hoist for Your Waterfront Operations

-

Top Benefits of Local Water Jet Cutting for Precision Manufacturing?

-

Understanding the Benefits of Water Jet Cutting Machines in Modern Manufacturing

-

What is Local Water Jet Cutting and How Does It Work?