Why Choose Waterjet Cutting Rubber for Your Manufacturing Needs?

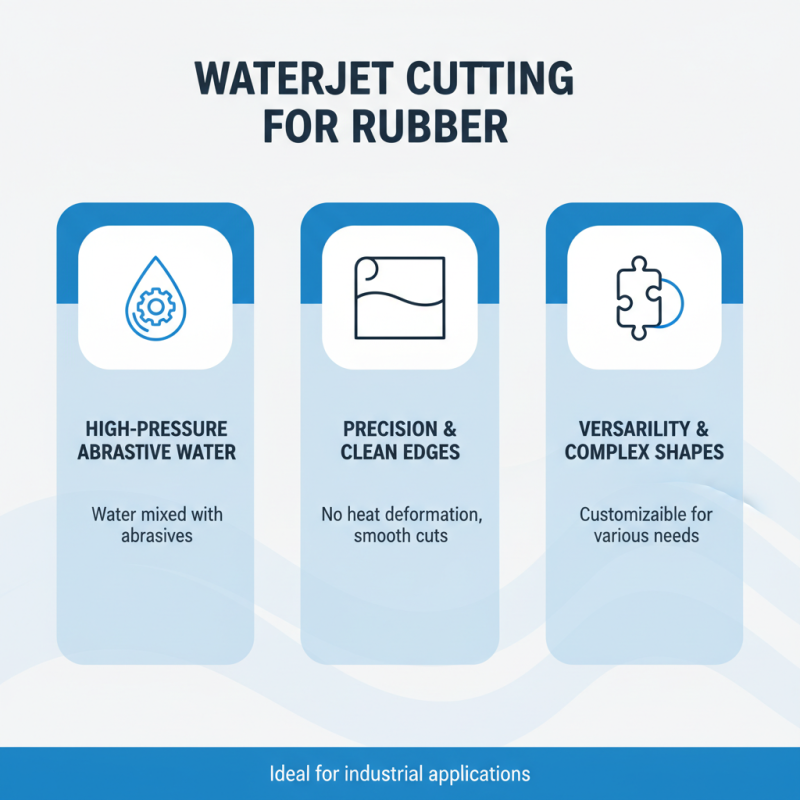

In the manufacturing world, the choice of cutting methods can significantly impact product quality and efficiency. Waterjet cutting rubber has gained attention as an innovative solution. Industry expert John Smith states, “Waterjet cutting rubber provides unmatched precision and flexibility for various applications.” This technique uses high-pressure water jets to slice through rubber materials, creating clean and intricate designs.

One notable advantage of waterjet cutting rubber is its capability to produce precise shapes without altering the material properties. Unlike traditional cutting methods, it doesn't generate heat, preserving the integrity of rubber. However, many manufacturers overlook this technology, often sticking to conventional methods that can lead to waste and inefficiency.

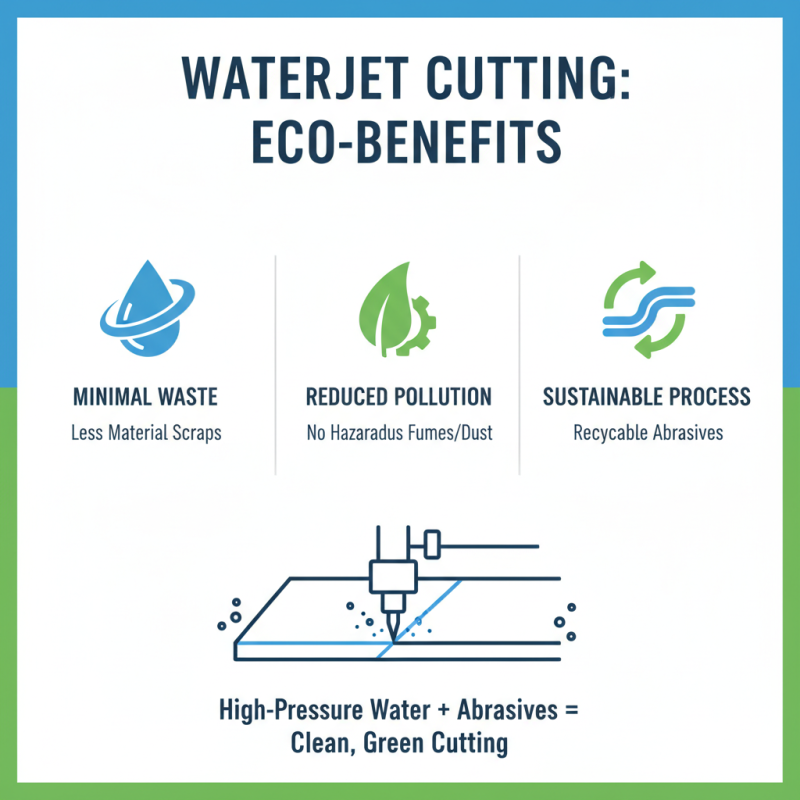

Adopting waterjet cutting rubber can also be beneficial for the environment. It produces minimal waste and does not emit harmful gases. Yet, the initial cost of the machinery may deter some businesses. The industry must reflect on the long-term benefits versus short-term expenses, as waterjet cutting could enhance both productivity and quality.

Advantages of Waterjet Cutting in Rubber Manufacturing

Waterjet cutting is a game-changer in rubber manufacturing. This technique uses high-pressure water to cut materials precisely. It is efficient for intricate designs that traditional methods struggle with. The process generates minimal heat, which keeps the rubber’s structural integrity intact. This is vital for items used in sensitive applications like automotive seals.

Another advantage of waterjet cutting is its versatility. It can handle various thicknesses and types of rubber. This flexibility allows manufacturers to experiment with different designs. However, companies must understand their specific needs before choosing this method. The initial setup can be complex, and operators need training to avoid mistakes. With proper knowledge, the potential of waterjet cutting becomes clear.

Additionally, the eco-friendly aspect of using waterjet technology is appealing. There are no harmful chemicals involved in the cutting process. This can reduce waste and promote sustainability. However, it is important to consider the water usage. Companies should implement recycling measures to optimize resource use. Balancing these factors is crucial for effective manufacturing.

Why Choose Waterjet Cutting Rubber for Your Manufacturing Needs? - Advantages of Waterjet Cutting in Rubber Manufacturing

| Advantage | Description | Applications |

|---|---|---|

| Precision Cutting | Waterjet cutting allows for intricate designs with tight tolerances. | Gaskets, seals, and complex parts. |

| Material Versatility | Can cut a wide range of rubber types and densities without changing tooling. | Industrial applications across various sectors. |

| Environmentally Friendly | Uses water and minimal energy, reducing waste and emissions compared to traditional cutting methods. | Sustainable manufacturing practices. |

| No Heat-Affected Zone | Eliminates heat distortion, preserving the properties of rubber. | Sensitive applications where material integrity is crucial. |

| Reduced Material Waste | Maximizes use of raw materials with precise cuts, minimizing scrap. | Cost-effective production with less waste. |

Comparison of Waterjet Cutting vs Traditional Cutting Methods

Waterjet cutting has gained popularity in various manufacturing sectors. This technique is particularly effective for cutting rubber. It uses high-pressure water mixed with abrasives. Since it does not introduce heat, it preserves the material's properties.

Traditional cutting methods, such as die cutting, can cause deformation in rubber. They often generate heat that alters the rubber’s composition. Waterjet cutting avoids this problem, ensuring accuracy and consistency. The process can create intricate designs without shredding the material.

**Tip:** Always consider the material type when choosing a cutting method. Different materials respond differently to various cutting techniques. Additionally, it's essential to assess the complexity of your desired design. A simpler cut may benefit from traditional methods. For complex designs, waterjet cutting may be the better choice.

Comparison of Waterjet Cutting vs Traditional Cutting Methods

Applications of Waterjet-Cut Rubber in Various Industries

Waterjet cutting is increasingly popular for rubber in various industries. This method uses high-pressure water mixed with abrasive materials to cut through rubber efficiently. It provides clean edges and precise shapes, which are essential in many applications. The versatility of waterjet cutting makes it suitable for different project needs.

In the automotive sector, waterjet-cut rubber parts are used for seals, gaskets, and noise reduction components. The accuracy of waterjet cutting ensures these parts fit perfectly, reducing potential leaks and performance issues. In aerospace, custom rubber components are crucial for safety and performance. Waterjet cutters can create complex designs that meet strict industry standards.

Healthcare is another field where waterjet-cut rubber plays a vital role. From medical device components to surgical pads, the precision cutting technology enhances product quality. However, the process requires careful consideration of materials and thickness. Environmental sustainability is also a concern. Using rubber waste in production can pose challenges for manufacturers. Balancing efficiency and responsibility remains an ongoing challenge in the industry.

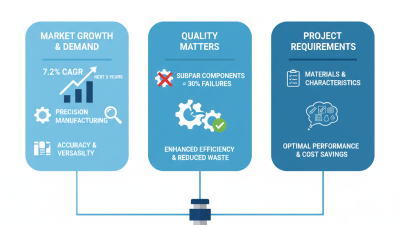

Cost-Effectiveness of Waterjet Cutting for Rubber Products

Waterjet cutting is a popular choice for manufacturing rubber products. It offers impressive precision and versatility. The cost-effectiveness of waterjet cutting is noteworthy. Businesses can save money while achieving high-quality results.

Using waterjet technology reduces waste significantly. Traditional cutting methods often lead to excess material loss. With waterjet, the kerf is minimal. This means more usable rubber remains. Lower waste translates to lower costs, making this method attractive for manufacturers.

Tips: Always evaluate your project requirements carefully. Understand the thickness of rubber you need to cut. Even minor miscalculations can lead to added costs. Also, consider the design complexity. Simple shapes are quicker and cheaper to produce.

Investing in waterjet cutting may seem high initially. However, the long-term savings on materials and labor can be substantial. It's essential to compare different manufacturing methods. Doing so helps ensure you choose the most efficient and cost-effective solution for your needs.

Environmental Benefits of Using Waterjet Cutting Technology

Waterjet cutting technology has gained popularity in various manufacturing sectors. It offers notable environmental benefits that can enhance sustainable practices. For instance, this method uses high-pressure water mixed with abrasives to cut materials like rubber. This process generates minimal waste compared to traditional cutting techniques, which often leave behind scraps to discard. Reducing waste is crucial in today’s eco-conscious world.

Additionally, waterjet cutting eliminates the need for toxic chemicals. Many cutting methods require hazardous substances for cleaning and finishing materials. In contrast, waterjet cutting uses only water, making it a safer choice for the environment. It also reduces air pollution, as it doesn’t release harmful emissions. However, it is worth noting that energy consumption in waterjet systems could be further optimized. While the technology is efficient, improving energy use remains a challenge.

Moreover, waterjet cutting generates less noise during operation. This is beneficial for workers' health and overall workplace safety. Yet, there may still be areas for improvement in terms of overall energy efficiency and water usage. Striving for innovations in these areas can enhance the sustainability of this method. As industries look for greener options, refining waterjet technology will be essential to meet demanding environmental standards.

Related Posts

-

Why Choose Waterjet Cutting Services in Seattle for Your Precision Needs?

-

Top Tips for Maintaining Waterjet Cutting Parts for Optimal Performance

-

Why is Waterjet Cutting the Best Choice for Precision Manufacturing

-

2026 Best Waterjet Cutting Aluminum Techniques for Precision Manufacturing?

-

Top Advantages of 3D Waterjet Cutting for Modern Manufacturing?

-

How to Select the Right Waterjet Cutting Parts for Your Project?