2025 How to Choose the Best Hoist Cover for Your Lifting Equipment

In the realm of lifting equipment, the importance of safeguarding machinery and ensuring longevity cannot be overstated. A crucial component in this ecosystem is the hoist cover, designed to protect lifting gear from environmental factors such as dust, moisture, and UV radiation. According to a recent industry report by MarketsandMarkets, the global hoist market is projected to grow significantly, driven by rising infrastructure developments and increased demand for efficient lifting solutions. This growth underscores the necessity of not only investing in high-quality lifting equipment but also in proper protection, which hoist covers provide.

Selecting the best hoist cover is pivotal for maintaining the performance and durability of lifting equipment. With varying materials and designs available, understanding the specific needs of your equipment is essential. The right hoist cover not only extends the life of the hoisting apparatus but also minimizes maintenance costs—a critical consideration in today’s competitive industrial landscape. Furthermore, a report by Technavio indicates that a significant percentage of equipment failures can be attributed to inadequate protection from environmental wear and tear. Thus, choosing the appropriate hoist cover should be a strategic decision that enhances operational efficiency and maximizes return on investment.

How Hoist Covers Enhance the Longevity of Lifting Equipment

When it comes to protecting lifting equipment, hoist covers play a crucial role in enhancing longevity and ultimately reducing operational costs. According to a recent report by the Industrial Lift and Hoist Association (ILHA), well-maintained lifting equipment can see its lifespan extended by up to 30% when protective measures like hoist covers are employed. These covers shield equipment from harsh environmental elements, including rain, dust, and UV rays, which can cause significant wear and tear over time. This protective barrier not only safeguards the physical integrity of the machinery but also prevents costly repairs and equipment downtime.

Moreover, the investment in high-quality hoist covers is justified by their ability to minimize maintenance needs. A study conducted by the Machinery Maintenance Association found that companies that utilized covers reported a 25% decrease in maintenance-related expenses. By preventing the accumulation of dust and moisture, hoist covers reduce the risk of rust and corrosion, which are significant factors in the degradation of lifting equipment. In industries where safety and reliability are paramount, the use of hoist covers is an effective strategy for ensuring that equipment remains in optimal working condition, thereby enhancing overall productivity and safety on job sites.

Factors to Consider When Selecting Hoist Covers for Your Equipment

When selecting hoist covers for lifting equipment, several key factors must be considered to ensure optimal protection and functionality. One primary consideration is the material of the cover. Durable fabrics such as heavy-duty polyester or vinyl are often recommended due to their resistance to UV rays, moisture, and abrasions. According to a report from the Industrial Fabrics Association International (IFAI), covers made from high-quality UV-resistant materials can extend the life of lifting equipment by as much as 30%, highlighting the importance of selecting appropriate fabrics for longevity and durability.

Another important factor is the fit and design of the hoist cover. Covers should be tailored to the specific dimensions and shape of the lifting equipment to provide maximum protection against environmental factors such as dust, rain, and snow. A study conducted by the Lifting Equipment Engineers Association (LEEA) found that improperly fitted covers can lead to accelerated wear and tear on hoists, resulting in increased maintenance costs. Additionally, features such as reinforced seams, ventilation panels, and adjustable straps can enhance the utility of hoist covers, ensuring they stay secure during adverse weather conditions while also allowing for necessary air circulation to prevent moisture buildup.

Lastly, the weight and ease of installation should also be taken into account. A cover that is too heavy can complicate storage and handling, while one that is lightweight might not provide adequate protection. According to data from the Occupational Safety and Health Administration (OSHA), proper installation of protective gear is critical for maintaining safety standards, which can be affected by cumbersome or complex cover designs. Optimal selection hinges on balancing these factors, ensuring that the hoist cover serves both protective and practical purposes in safeguarding equipment.

Material Types: Analyzing Durability and Weather Resistance in Hoist Covers

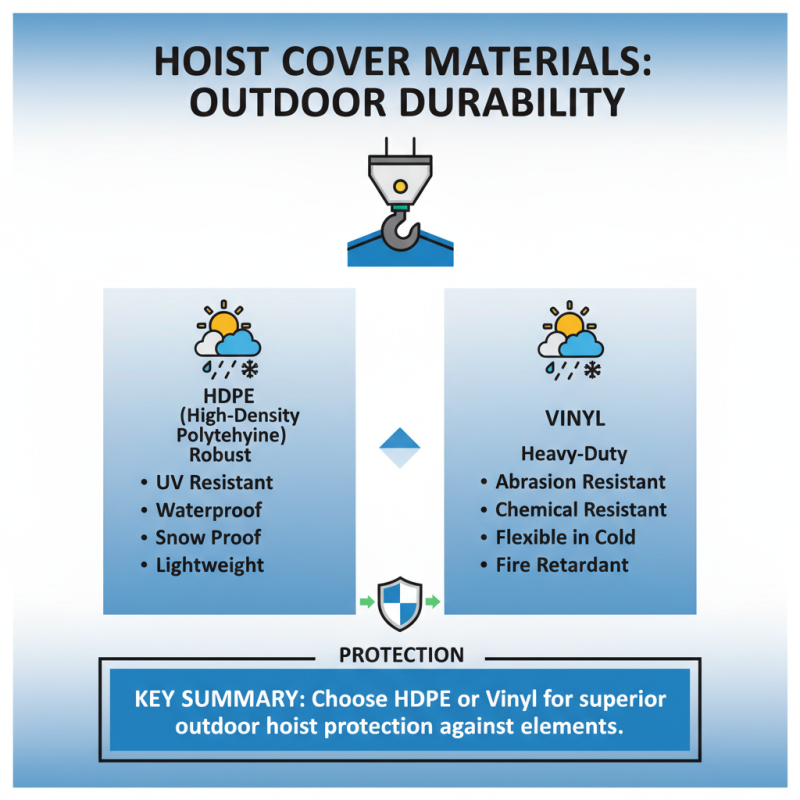

When selecting a hoist cover for lifting equipment, one of the most critical aspects to consider is the material type, particularly its durability and weather resistance. For outdoor use, covers made from high-density polyethylene (HDPE) or vinyl are often preferred due to their robustness and ability to withstand harsh weather conditions. These materials provide a strong barrier against UV rays, rain, and snow, ensuring that your equipment remains protected from potential damage that can be caused by prolonged exposure to the elements.

Another important factor is the thickness of the material, which plays a significant role in the cover's overall durability. Thicker materials not only offer better protection but also enhance resistance to tearing and abrasion, which can occur during day-to-day use or storage. Furthermore, some materials are treated with special coatings to enhance their water repellency and mildew resistance, making them a wise investment for those who need long-lasting protection for their lifting equipment, regardless of environmental challenges. By carefully assessing the material properties, users can ensure they select a hoist cover that meets their specific needs and extends the lifespan of their valuable equipment.

Industry Standards and Certifications for Hoist Cover Selection

When selecting a hoist cover for lifting equipment, understanding industry standards and certifications is crucial for ensuring safety and performance. Various organizations set guidelines that specify the materials, design, and performance criteria for hoist covers. These standards help in determining durability, resistance to environmental factors, and overall suitability for intended applications. Familiarity with these standards enables users to make informed decisions and select products that meet regulatory requirements while providing optimal protection for their lifting equipment.

In addition to compliance with industry standards, certifications play a pivotal role in the selection process. Products that carry recognized certifications have undergone rigorous testing to demonstrate their effectiveness and reliability. This can include assessments for UV resistance, water resistance, and tear strength, among others. When choosing a hoist cover, it is important to verify that the product has the appropriate certifications relevant to its intended use, as this can be an indicator of quality and longevity. By prioritizing standards and certifications, users can maximize safety and performance in their operations.

Cost-Benefit Analysis: Investing in Quality Hoist Covers for Safety

When considering the investment in hoist covers for lifting equipment, a comprehensive cost-benefit analysis reveals their significance in enhancing safety and prolonging equipment lifespan. Quality hoist covers act as a protective barrier against environmental factors such as dust, moisture, and UV rays, all of which can lead to corrosion and degradation of lifting mechanisms. By preventing such damage, these covers reduce the frequency and cost of repairs, thereby offering substantial long-term savings to businesses.

Moreover, investing in quality hoist covers also contributes to safety in the workplace. They help ensure that lifting equipment remains in optimal working condition, reducing the risk of accidents stemming from equipment failure. A well-maintained hoisting system not only protects employees but also promotes operational efficiency, as safe and reliable equipment can increase productivity. In summary, while the initial purchase of high-quality hoist covers may seem like an additional expense, the potential savings from reduced repairs and enhanced safety measures make it a prudent investment for any organization committed to maintaining their lifting equipment effectively.

2025 How to Choose the Best Hoist Cover for Your Lifting Equipment - Cost-Benefit Analysis: Investing in Quality Hoist Covers for Safety

| Feature | Budget Option | Mid-range Option | Premium Option |

|---|---|---|---|

| Material Quality | Basic Polyester | High-Density Nylon | Heavy-Duty Vinyl |

| Water Resistance | Low | Moderate | High |

| UV Resistance | No | Yes | Yes, Enhanced |

| Warranty | 1 Year | 2 Years | 3 Years |

| Price Range | $30 - $50 | $50 - $100 | $100 - $200 |

| Recommended Usage | Indoor | Indoor/Outdoor | Heavy Outdoor Use |

Related Posts

-

Why Choose Waterjet Cutting Services in Seattle for Your Precision Needs?

-

Unlocking Efficiency: How Dock Hoists Revolutionize Maritime Operations and Improve Safety

-

Top 10 Benefits of Using a Dock Hoist for Your Waterfront Operations

-

2025 Top 5 Water Jet Cutting Accuracy Innovations for Precision Manufacturing

-

Understanding the Benefits of Jet Cut Technology in Modern Manufacturing

-

Why You Should Consider a Lift Dock for Your Waterfront Property