2026 How to Choose the Right Water Jet Cutting Solutions for Your Needs?

Choosing the right water jet cutting solutions can be daunting. As industries evolve, the demand for precision and efficiency grows. Water jet cutting is versatile and effective, but not all systems are created equal. The right choice depends on specific needs and applications.

Factors such as material type, thickness, and desired finish matter. You might need a high-pressure system for harder materials. Alternatively, softer materials may require a more delicate approach. Understanding your projects is crucial. It is also important to consider the budget and maintenance aspects of these solutions.

Often, businesses overlook factors like the size of equipment. A large machine may seem appealing, but space constraints can complicate usage. Regular assessments ensure that the water jet cutting solutions you choose remain effective over time. Reflecting on past purchases can offer insights into future decisions. Ultimately, the goal is to find a balance between performance and practicality.

Understanding Water Jet Cutting Technology

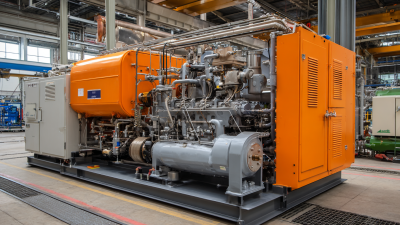

Water jet cutting technology has advanced significantly, revolutionizing various industries. This method uses high-pressure water mixed with abrasive materials to cut through various materials. Reports suggest that the global water jet cutting market is expected to reach $2.5 billion by 2026. This growth indicates a preference for precise, clean cuts without altering material properties.

Understanding the core principles of water jet cutting is crucial for making informed decisions. The process generates less heat, minimizing thermal distortion in materials. For example, cutting metal sheets often maintains their structural integrity. Additionally, water jet cutting is environmentally friendly, producing minimal waste. Studies reveal that over 80% of companies prioritize sustainable practices, making water jet solutions increasingly attractive.

However, selecting the right technology can be challenging. Various factors influence the choice, such as material type and thickness. Not all projects benefit equally from water jet cutting. It's essential to evaluate specific needs carefully. Mistakes can lead to inefficient operations or excessive costs. Balancing technical specifications with practical applications demands attention and foresight.

Identifying Your Specific Cutting Needs

Choosing the right water jet cutting solutions starts with understanding your specific cutting needs. Identifying the material type is crucial. Metals, plastics, and ceramics each require different pressure levels and abrasives. For instance, cutting steel might need 60,000 psi, while softer materials require less power. This precision ensures efficiency and reduces waste during the cutting process.

Consider the thickness of the material as well. According to a recent industry report, 40% of users misjudge the thickness they work with. This can lead to poor cut quality or excessive wear on the machine. If your project involves variable thickness, you need a versatile water jet cutter. Many solutions can adapt to different ranges, but not all have the same capabilities.

Also, look at the overall production volume. Data shows that 30% of manufacturers underestimate their needs, leading to equipment bottlenecks. A machine that meets a project's current demand may struggle with future projects. Analyze your production trends carefully to avoid buying underperforming solutions. Balancing immediate needs with future growth can streamline your operations.

2026 How to Choose the Right Water Jet Cutting Solutions for Your Needs? - Identifying Your Specific Cutting Needs

| Cutting Material | Thickness Range (inches) | Cutting Accuracy (inches) | Recommended Pressure (psi) | Typical Applications |

|---|---|---|---|---|

| Metal | 0.01 - 6 | 0.003 | 50,000 | Aerospace, Automotive |

| Glass | 0.01 - 1 | 0.002 | 40,000 | Art, Architecture |

| Ceramics | 0.01 - 2 | 0.005 | 60,000 | Consumer Goods, Tiles |

| Plastic | 0.01 - 4 | 0.004 | 30,000 | Packaging, Components |

| Stone | 0.01 - 8 | 0.005 | 70,000 | Construction, Memorials |

Evaluating Different Water Jet Cutting Machines

When evaluating different water jet cutting machines, consider the material types you'll be working with. Various materials, from thin metals to thick ceramics, require different pressures and nozzle designs. The right water jet machine should match the thickness of your materials. This ensures clean cuts and reduces waste. If the machine isn't suited for your specific application, results may be subpar.

Another factor to think about is the versatility of the machine. Some models are designed for specific tasks, while others can handle various projects. If you only focus on one type of cutting, a specialized machine might suit you better. However, if you foresee diverse projects, a more flexible solution will save time and money in the long run.

It’s also essential to examine the machine’s precision and speed. While high-speed cutting is appealing, accuracy is paramount. A machine that cuts fast but requires constant recalibration can lead to frustration. Reflect on your workflow: will speed or precision impact your production more? Balancing these aspects is a critical part of choosing the right water jet cutting solution for your precise needs.

Comparing Costs and Efficiency of Water Jet Solutions

When choosing water jet cutting solutions, cost and efficiency play crucial roles. Different applications demand varying levels of precision and material types. Understanding your project can help narrow down the options. For example, cutting metals requires powerful jets, while softer materials like foam need less force. Costs vary widely based on the equipment and operational complexity.

Efficiency is also key. High-speed cutting can save time but may lead to higher costs. Users often overlook maintenance costs, which can add up. Some machines may seem cheaper initially but will incur more over time. A clear cost-benefit analysis can help you better understand the true investment required.

Balancing cost and efficiency sometimes feels tricky. Finding the sweet spot requires careful consideration. You might find yourself questioning whether to invest more for better performance. Adapting your choice to your needs is critical. Trial and error can lead to significant revelations about what works best for your specific requirements.

Selecting the Right Supplier and Support Services

Choosing the right supplier for water jet cutting solutions can be challenging. You'll want to partner with someone knowledgeable and reliable. Look for suppliers who have a solid reputation in your industry. They should be open to communication and willing to listen to your needs. Relationships matter in this field. A good supplier will offer support services that help you through the installation and maintenance processes.

Tips: Ask for references from previous clients. This can provide insight into their reliability. Check online reviews too; they often reveal important details about customer experiences.

Evaluate the support services offered. Does the supplier provide training for your team? Are there service packages for ongoing support? These elements are key to ensuring your investment is successful. Remember, poor support can lead to costly downtime, so choose wisely.

Consider the technologies they use. Advanced technology often translates to better performance. Keep yourself updated on the latest trends. This way, you can ask informed questions and make the best choice for your needs. Your selections will impact your operations directly. Taking the time to evaluate your options is crucial.

Related Posts

-

Maximize Precision and Efficiency with Local Water Jet Cutting: The Future of Material Processing

-

Unlocking Precision: How Water Jet Cutting Systems Revolutionize Metal Fabrication with 0.005-Inch Accuracy

-

Best Water Jet Cutting Machines for Precision Cutting?

-

Exploring the Benefits of Water Jet Cutting for Precision Stainless Steel Fabrication

-

Understanding the Benefits of Water Jet Cutting Machines in Modern Manufacturing

-

2025 Top 5 Water Jet Cutting Accuracy Innovations for Precision Manufacturing