How to Choose the Right Dock Hoist for Your Industrial Needs

Choosing the right dock hoist for your industrial operations is crucial to ensure efficiency and safety in material handling. With various options available in the market, making an informed decision can be overwhelming. As Jack Thompson, a leading expert in the dock hoist industry, aptly puts it, "A well-selected dock hoist not only boosts productivity but also enhances workplace safety." Understanding the specific requirements of your operations and the capabilities of different dock hoists is essential for maximizing their benefits.

Dock hoists play a vital role in logistics, warehousing, and manufacturing, providing a reliable solution for lifting and transporting heavy loads. When businesses consider investing in a dock hoist, they must evaluate factors such as load capacity, lifting height, and the working environment. Different industries may have unique challenges that require tailored solutions, making it imperative to choose a dock hoist that meets those specific needs. By doing so, companies can significantly improve their operational efficiency and reduce the risk of workplace accidents.

Understanding Dock Hoists: Definitions and Applications in Industry

Dock hoists are essential equipment in various industrial applications, primarily used for lifting and lowering heavy loads efficiently and safely. Defined as mechanical devices that utilize a pulley system or hydraulic mechanisms, dock hoists are prevalent in warehouses, shipping facilities, and manufacturing plants. According to a market research report by Grand View Research, the dock and freight hoist market is expected to reach USD 6.4 billion by 2025, indicating a growing demand that underscores their importance in modern industrial operations.

The applications of dock hoists extend beyond simple loading and unloading tasks. They play a crucial role in enhancing operational efficiency and safety in environments where heavy materials are frequently handled. For instance, in the construction industry, dock hoists facilitate the movement of building materials to elevated surfaces, reducing the risk of manual handling injuries. Furthermore, in sectors such as food and beverage, dock hoists are vital for maintaining hygiene standards by preventing unnecessary manual contact with products. The Occupational Safety and Health Administration (OSHA) reports a significant reduction in workplace injuries linked to the use of mechanized lifting devices like dock hoists, reinforcing their value in industrial safety protocols.

Dock Hoists Load Capacity Comparison

Key Considerations in Selecting the Right Dock Hoist for Various Loads

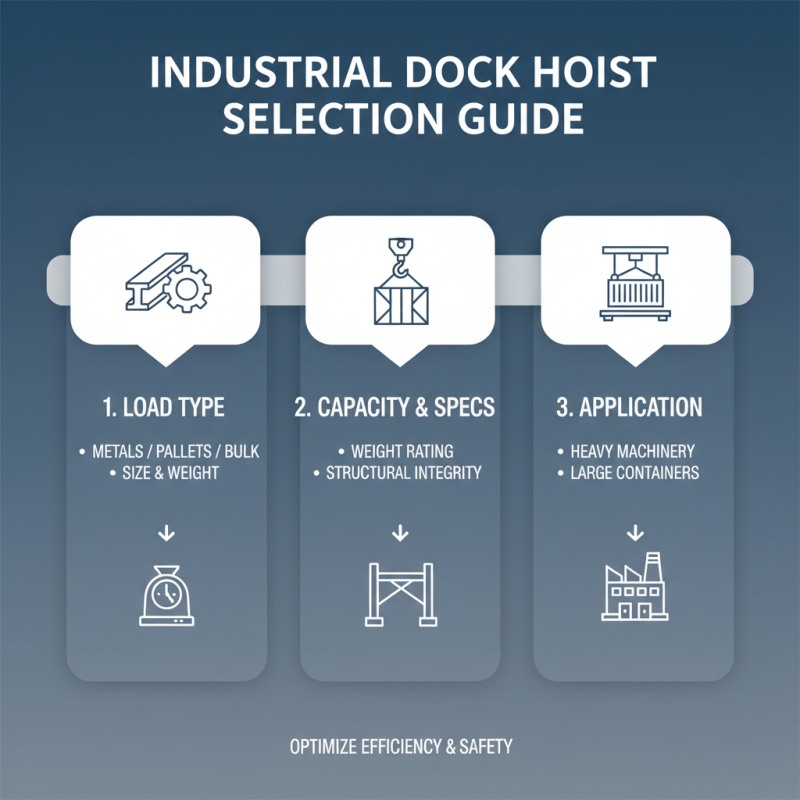

When selecting a dock hoist for industrial needs, it's crucial to consider the specific types of loads you will be handling. Different materials—such as metals, pallets, or bulk items—can vary significantly in weight and size. Understanding these characteristics will help determine the load capacity and specifications necessary for the hoist. For example, if your operations involve heavy machinery or large containers, you'll need a hoist with a higher weight rating and robust structural integrity.

**Tips:** Before purchasing, assess your daily load types and their weights to ensure the dock hoist can accommodate as needed. Additionally, think about the typical dimensions of the loads, as this may dictate the design of the hoist and its features, such as lifting height and reach.

Another vital consideration is the frequency of use. If your dock hoist will undergo continuous daily operation, investing in a commercial-grade unit may be necessary. Conversely, a lighter-duty hoist may suffice for occasional use. It's also important to factor in environmental conditions—will the hoist be used indoors or outdoors? Exposure to the elements can influence the materials and protective features required for longevity.

**Tips:** Evaluate maintenance needs as well; some models require more upkeep than others, and this can impact your operational costs over time. Always consult with a professional when determining the right specifications for your dock hoist to ensure efficiency and safety in your industrial processes.

Evaluating Load Capacity: Industry Standards and Safety Regulations

When selecting the right dock hoist for your industrial operations, understanding load capacity is crucial. Different industries have varying standards for load capacity and safety regulations, which are designed to protect both workers and equipment. It’s essential to evaluate the maximum weight a dock hoist can handle before making a purchase. This includes considering the weight of the materials you'll be lifting, and ensuring that the hoist can accommodate any potential overload situations. Checking compliance with industry standards such as ASME or OSHA can provide valuable insights into the appropriate load limits for your specific application.

Tips for assessing load capacity include conducting a detailed inventory of the goods you intend to lift, including their weight and dimensions. This will help you determine the necessary specifications for your dock hoist. Additionally, consult with safety regulations from your local authority to ensure that the chosen equipment meets all necessary legal requirements. Regular testing and maintenance are also recommended to verify that the hoist continues to operate safely under its intended load. Being proactive about these considerations not only enhances operational efficiency but also ensures the safety of your workforce.

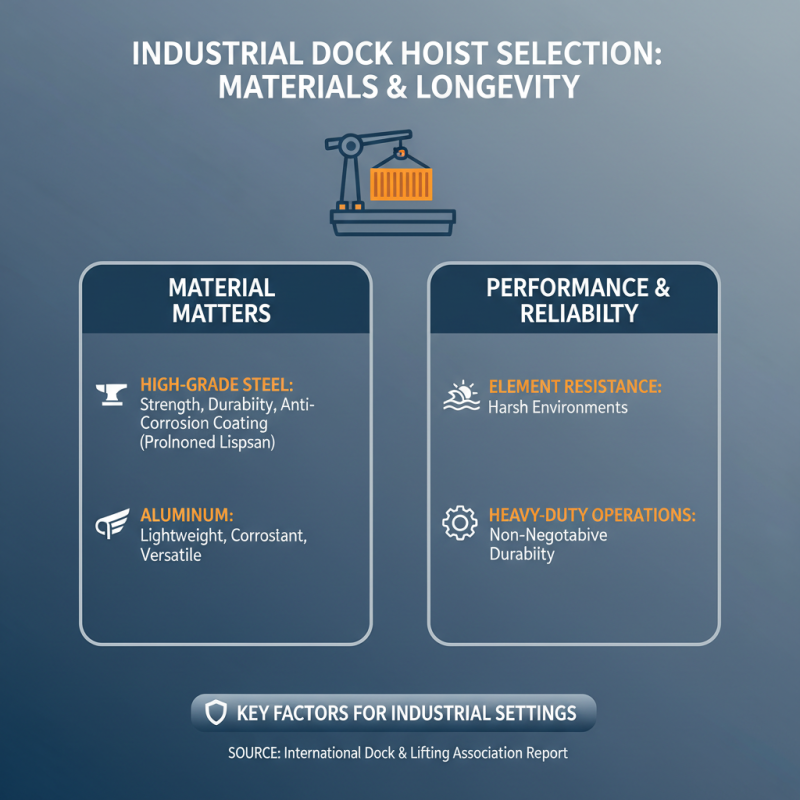

Material and Construction: Choosing Durable Dock Hoist Designs

When selecting a dock hoist, the material and construction quality are paramount to ensure longevity and reliability in industrial settings. According to a report by the International Dock and Lifting Association, the choice of materials can significantly affect not only the performance of the dock hoist but also its resistance to the elements. For example, materials like high-grade steel and aluminum are favored for their strength and corrosion resistance. Steel, when treated with anti-corrosion coatings, can provide a lifespan extension, making it suitable for heavy-duty operations where durability is non-negotiable.

Additionally, construction techniques play a crucial role in the dock hoist’s effectiveness. A well-designed hoist incorporates features such as reinforced joints and pulleys that can withstand high loads and repetitive use. A study conducted by the Industrial Equipment Research Group highlighted that dock hoists with integrated safety mechanisms and robust structural designs can reduce maintenance costs by up to 30%, showcasing the importance of investing in durable construction. Therefore, industries must consider these aspects carefully, ensuring that their chosen dock hoist meets the rigorous demands of their operational environment.

Maintenance and Operational Efficiency for Long-term Dock Hoist Use

When selecting a dock hoist for industrial applications, maintenance and operational efficiency are crucial aspects that often determine long-term performance. Regular maintenance practices not only extend the lifespan of the hoist but also ensure that it operates at peak efficiency. This includes routine inspections of the structural integrity, mechanical components, and safety mechanisms. Developing a maintenance schedule based on the manufacturer's guidelines and adhering to it can prevent unexpected breakdowns and costly repairs.

Operational efficiency is significantly influenced by the correct usage of the dock hoist. Training operators on best practices, including load limits and proper rigging techniques, can minimize wear and tear on the equipment. Additionally, assessing the working environment for potential hazards, such as slipping or obstruction, can further optimize performance. Incorporating technology, such as load monitoring systems, can also enhance operational oversight, ensuring that the hoist is used within its intended parameters for greater safety and efficiency.

Related Posts

-

Unlocking Efficiency: How Dock Hoists Revolutionize Maritime Operations and Improve Safety

-

The Ultimate Guide to Understanding How a Water Jet Head Transforms Industrial Cutting

-

The Future of Cutting Technologies Exploring the Benefits of Water Jet Abrasive Systems

-

Exploring the Benefits of Water Jet Cutting for Precision Stainless Steel Fabrication

-

Unlocking Precision: How Water Jet Cutting Systems Revolutionize Metal Fabrication with 0.005-Inch Accuracy

-

Why You Should Consider a Jet Water Machine for Your Cleaning Needs