How to Choose the Best Abrasive Water Jet Cutting for Your Project

Abrasive water jet cutting has emerged as a transformative technology in various industries, providing unparalleled precision and versatility in material processing. According to the latest industry report by IBISWorld, the global market for water jet cutting technology is projected to grow by 7.7% annually, reaching a valuation of $1.45 billion by 2025. This growth is driven by the increasing demand for high-quality cutting solutions across sectors such as aerospace, automotive, and manufacturing, where accuracy and minimal material waste are critical.

Experts in the field emphasize the importance of choosing the right abrasive water jet cutting approach for specific projects. Dr. Emily Carter, a renowned engineering consultant specializing in advanced manufacturing technologies, states, "Selecting the optimal abrasive water jet cutting method can significantly enhance operational efficiency and reduce production costs." Her insights underscore the necessity of understanding the various factors that influence the effectiveness of water jet cutting systems, including abrasive materials, cutting speed, and the type of substrate being processed.

In the rapidly evolving landscape of manufacturing, decision-makers must navigate through the complexities of abrasive water jet cutting to maximize the benefits for their projects. Understanding the key components and innovations within this technology will not only help in achieving superior cutting results but also ensure that businesses remain competitive in an increasingly demanding marketplace.

Factors to Consider When Selecting Abrasive Water Jet Cutting

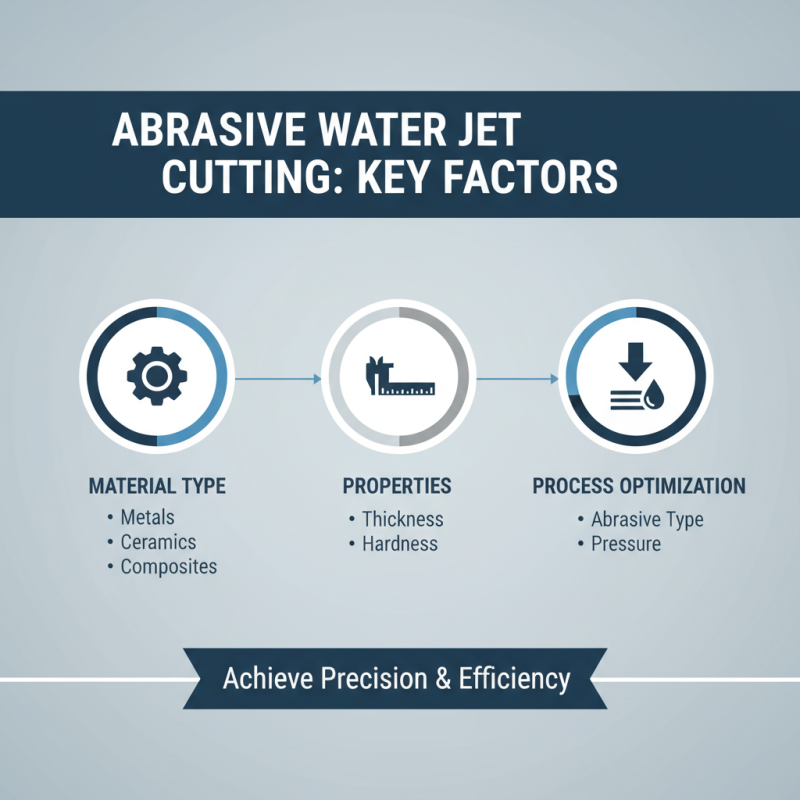

When selecting abrasive water jet cutting for your project, several key factors must be considered to ensure you achieve the desired results. First and foremost is the material you plan to cut. Different materials—such as metals, ceramics, and composites—require specific types of abrasive materials and pressures to optimize the cutting process. Understanding the properties of your material, including thickness and hardness, will directly influence the efficiency and precision of the cut.

Another crucial factor is the desired tolerance and finish quality of the cut. If your project demands high precision and tight tolerances, selecting a water jet system that offers advanced control features is essential. Additionally, consider the cutting speed and productivity required for your project timeline. Different machines offer varying capabilities in terms of speed and efficiency, which can impact project costs and timelines. Finally, evaluate the operational costs associated with water jet cutting, including maintenance needs and the expense of consumables, to align this process with your overall project budget.

Understanding Different Types of Abrasive Water Jet Machines

Abrasive water jet cutting machines come in various types, each tailored to specific applications and materials. The most common types are pure water jet machines, abrasive water jet machines, and dual-function systems. Pure water jet machines use high-pressure water alone to cut softer materials like plastics and foams, while abrasive water jet machines mix a stream of water with abrasives such as garnet to effectively cut through harder materials, including metals and ceramics. This versatility makes abrasive water jet cutting an attractive option for industries requiring precision and adaptability.

When choosing an abrasive water jet machine, it’s essential to consider factors like cutting speed, thickness capabilities, and the type of abrasive material used. For instance, some machines are designed for high-speed cutting, making them suitable for projects with stringent time constraints. Others may excel in cutting thicker materials but at a slower speed. Additionally, the choice of abrasive can impact the quality of the cut and wear on the machine's components. Understanding these different types and their specifications allows you to select the right machine for your project's demands, ensuring efficiency and precision in your cutting tasks.

How to Choose the Best Abrasive Water Jet Cutting for Your Project

| Type of Machine | Cutting Pressure (PSI) | Abrasive Material | Material Thickness Capability (inches) | Typical Applications |

|---|---|---|---|---|

| Standard Abrasive Water Jet | 60,000 | Garnet | 4 | Metal, Stone Cutting |

| Micro Abrasive Water Jet | 50,000 | Alumina | 0.25 | Precision Cutting, Small Parts |

| High-Pressure Water Jet | 90,000 | Garnet | 6 | Thick Metal Sections, Composites |

| Robotic Water Jet Cutting | 80,000 | Garnet | 5 | Complex Shapes, High Volume Production |

Evaluating Material Compatibility with Water Jet Cutting

When selecting the best abrasive water jet cutting method for your project, material compatibility is a crucial factor to consider. Water jet cutting is versatile and can effectively cut various materials, ranging from metals and plastics to composites and ceramics. Understanding how these materials interact with water jet technology is essential for achieving optimal results. For instance, softer materials like plastics may cut effectively without the need for abrasive compounds, while harder materials such as steel or granite require abrasives to enhance cutting efficiency and precision.

Additionally, the thickness of the material plays an important role in determining the appropriate water jet cutting technique. Thicker materials often necessitate higher pressure and a specific abrasive type to ensure clean edges and minimal kerf width. Moreover, some materials may react differently under high-pressure water jet streams, leading to issues such as warping or undesirable surface finishes. Therefore, conducting material tests or consulting with cutting experts can provide valuable insights into the best approaches for various material types, ensuring that the selected method aligns with project requirements while maintaining quality and accuracy.

Cost Analysis: Budgeting for Abrasive Water Jet Cutting Services

When budgeting for abrasive water jet cutting services, it's essential to consider various cost factors that can significantly impact your project's financial plan. According to a recent industry report, the average cost of abrasive water jet cutting ranges from $100 to $200 per hour, depending on materials and complexity. Additionally, it's important to account for material costs, which can vary widely; for example, aluminum might cost less than hardened steel, thus influencing the overall budget.

Tips for effective budgeting include obtaining multiple quotes to gain a clearer understanding of market rates and ensuring the quote includes all potential costs—such as setup fees, material procurement, and post-cutting processes. Furthermore, consider the thickness of the materials; thicker materials typically require more time and abrasive, thereby increasing costs.

Another important factor is the level of precision required for your project. Higher precision often correlates with technology selection and setup complexity, which can raise expenses significantly. A detailed project scope can help manage expectations and prevent unexpected costs, leading to more efficient budget allocation. Always remember that investing in quality services can lead to better outcomes and reduce rework costs in the long run.

Cost Analysis of Abrasive Water Jet Cutting Services

Assessing the Precision and Quality of Cutting Results

When selecting the best abrasive water jet cutting method for your project, it's crucial to closely examine the precision and quality of the cutting results. High precision is vital, especially in applications where tight tolerances are necessary. The unique ability of abrasive water jet cutting to produce intricate designs with minimal kerf ensures clean cut edges, making it an ideal choice for complex materials. Assessing the machinery’s capabilities, including the nozzle size and the type of abrasives used, can significantly influence the quality of the final output.

Tips: Always ask for sample cuts before making a commitment. This will give you insight into the precision levels and surface finish you can expect from your chosen cutting service. Additionally, consider the thickness and type of material when evaluating cutting quality; different materials can react differently under the cutting process.

Finally, it’s important to evaluate the experience and expertise of the service provider. A knowledgeable operator can optimize the cutting parameters, resulting in enhanced final product quality. Engaging with professionals who have a track record of delivering high-quality results will help safeguard your project’s standards.

Related Posts

-

How to Use Water Jet Cutting for Steel: A Complete Guide

-

Maximize Precision and Efficiency with Local Water Jet Cutting: The Future of Material Processing

-

Why Choose Waterjet Cutting Services in Seattle for Your Precision Needs?

-

Top 10 Benefits of Using a Dock Hoist for Your Waterfront Operations

-

The Ultimate Guide to Choosing the Right Disk Mower for Your Lawn Care Needs

-

What is Waterjet Cutting Titanium? Benefits, Process, and Applications Explained