What is the Best Geomembrane Welding Machine for Your Needs

Choosing the right geomembrane welding machine is crucial for construction and environmental projects. The global geomembrane market is projected to reach $3.6 billion by 2025, according to industry reports. This growth highlights the demand for effective welding solutions.

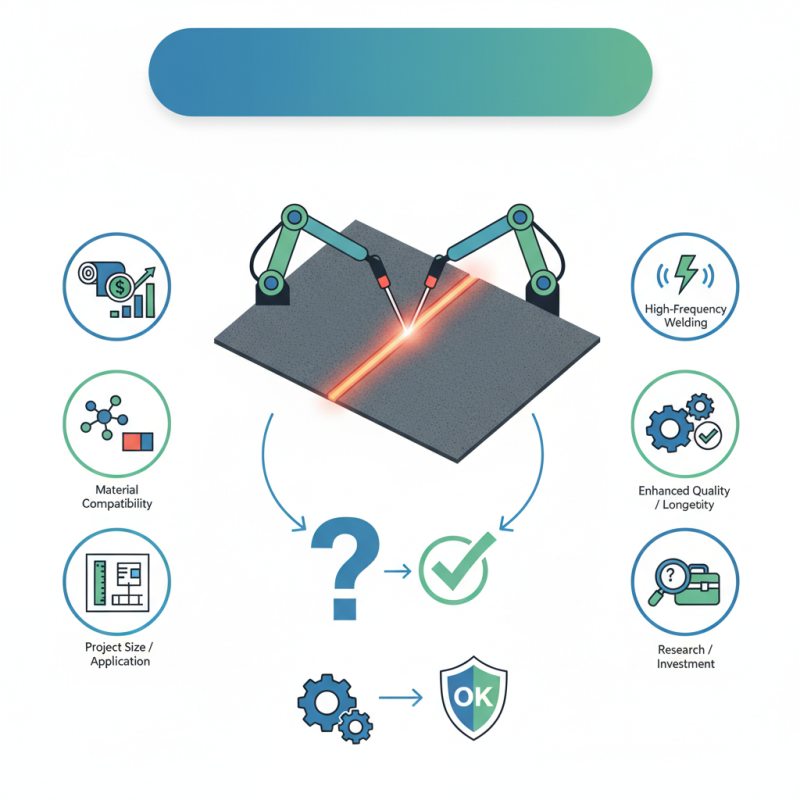

With different types of geomembrane materials available, the selection of welding machinery becomes more complex. Various factors come into play: material compatibility, project size, and specific application requirements. A machine that excels in one area may falter in another. For instance, high-frequency welding is efficient but might not suit all materials.

Understanding your specific needs is vital. The right machine will enhance the quality and longevity of the geomembrane. A mismatch can lead to costly repairs or early failures. Careful consideration of your project requirements and welding machine capabilities is essential. Investing time in research can yield significant long-term benefits.

Types of Geomembrane Welding Machines Available in the Market

When selecting a geomembrane welding machine, understanding the types available is crucial. There are several categories, including hot air welders, wedge welders, and extrusion welders. Each type has its unique application and technique. For example, hot air welders are often used for thinner geomembranes. They provide flexibility but may not be suitable for thicker materials.

Wedge welders, on the other hand, are effective for thicker geomembranes. These machines generate a fusion through heated wedges. Some reports indicate that up to 40% of geomembrane failures can be attributed to poor welding practices. Therefore, choosing the right machine is vital. The precision and efficiency of these devices are essential for strong seams.

Extrusion welders combine welding and material application. They are versatile but require skilled operators. Incorrect settings can lead to weak joints. Research shows that proper temperature settings should stay between 400°F and 500°F for optimal results. Understanding each type's benefits and constraints helps ensure the best choice for specific project needs.

Key Features to Consider When Choosing a Welding Machine

When choosing a geomembrane welding machine, several key features deserve attention. Consider the welding technology. Several methods exist, such as hot wedge and hot air. Each has unique advantages. A hot wedge machine offers precision, while hot air is more versatile. Evaluate which technology meets your needs best.

Next, think about the machine's power and temperature control. A powerful machine ensures it can handle thick materials. Temperature control affects the quality of welds. Great welds need consistent heat. Look for machines with adjustable temperature settings. Durability is also vital. Check the materials used in construction. An ideal machine should withstand harsh environments over time.

Don’t forget about portability. Some jobs require moving the equipment frequently. A lightweight machine may work better in such cases. However, heavier machines often offer better stability. This balance can be tricky. Also, consider user-friendliness in design. A complicated interface can slow you down. A simpler interface usually makes operation easier.

Comparative Analysis of Top Brands in Geomembrane Welding

When choosing a geomembrane welding machine, several factors come into play. Efficiency and precision are key. Different machines offer various features that impact the quality of the weld. Some machines allow for adjustable temperatures and speeds, ensuring versatility for multiple projects. Others may focus more on ease of use, which can be beneficial for beginners.

A closer look at popular models reveals a mix of strengths and weaknesses. Some models excel in producing strong seals but are less portable. Others are lightweight but may struggle with thicker materials. It's essential to evaluate the nature of your projects. For instance, if frequent site changes occur, portability might matter more than maximum output.

It's worth noting that not every advanced feature is necessary. Simplicity can lead to fewer malfunctions and easier repairs, an aspect often overlooked. The right balance between user requirements and machine capability is crucial. Users should reflect on their needs and the specific environments where the machines will operate to make a well-informed decision.

Best Practices for Using Geomembrane Welding Machines

When using geomembrane welding machines, adhering to best practices is crucial. Proper training on equipment use is essential. An experienced operator can significantly reduce the risk of errors. Misalignment issues are common and can lead to water leaks. Research shows that improper welding can decrease membrane lifespan by 20% or more. Therefore, ensuring precision during setup and execution is vital for project success.

Additionally, environmental factors must be considered. Wind speed, humidity, and temperature can all affect welding quality. For instance, high winds can cause complications with heat applications. It's recommended to check weather conditions before commencing welding work. Regular maintenance of equipment helps prevent failures too. Neglected machines can lead to inconsistent welds and increased downtime. Companies report that a lack of routine checks can increase repair costs by up to 30%.

Weld testing, including air pressure tests, should not be overlooked. These tests ensure the integrity of the seams. Data indicates that 15% of projects fail due to inadequate quality control measures. Operators must document inspections and results for future reference. Insufficient records can lead to accountability issues down the line. Each of these practices contributes vital aspects to the overall success of geomembrane installation projects.

Maintenance Tips for Prolonging the Life of Your Welding Equipment

Maintaining your welding equipment is crucial for optimal performance. Regular cleaning is essential. After each use, remove any debris or residue from the machine. This helps prevent buildup and ensures smooth operation. A clean machine can significantly reduce the likelihood of malfunctions. Remember, dust can accumulate in hard-to-reach areas.

Check the welding elements often. Inspect the heating elements and tips for wear and tear. These components are vital for effective welding. If you notice damage, replace them promptly. Delaying replacements can lead to poor weld quality. Proper care extends the life of these parts.

Store your equipment properly. Keep it in a dry, cool place to avoid rust and moisture damage. Using a protective cover can also shield it from dust. However, ensure the cover is breathable. Trapped moisture can cause more harm than good. Finally, don't forget to periodically review your maintenance routine. Reflect on what works and what doesn’t. Adapt as needed, and you’ll keep your welding machine in top shape.

What is the Best Geomembrane Welding Machine for Your Needs - Maintenance Tips for Prolonging the Life of Your Welding Equipment

| Machine Type | Welding Technology | Max Welding Speed (m/min) | Weight (kg) | Price Range (USD) | Maintenance Tips |

|---|---|---|---|---|---|

| Automatic Welding Machine | Hot Wedge | 6 | 50 | $3,000 - $5,000 | Regularly clean welding heads and check calibration. |

| Manual Welding Machine | Extrusion | 3 | 25 | $1,500 - $2,500 | Lubricate moving parts and inspect for wear. |

| Robotic Welding System | Machine Control | 8 | 100 | $10,000 - $15,000 | Perform software updates and maintain clear work area. |

| Small-Scale Handheld Welder | Heat Gun | 1.5 | 5 | $300 - $600 | Store in a dry place and check for electrical issues. |