Top 10 Benefits of Waterjet Cutting Titanium for Your Projects?

Waterjet cutting titanium has become increasingly popular for various projects. This innovative technique provides numerous advantages that can enhance your work. One significant benefit is precision. Waterjet cutting titanium offers intricate designs without compromising material integrity. The process uses high-pressure water mixed with abrasive materials, allowing for clean cuts even in thick titanium sheets.

Another vital aspect is versatility. Waterjet cutting can handle different thicknesses and shapes, making it suitable for diverse applications. This adaptability allows businesses to tackle unique projects with ease. Additionally, the cold cutting nature of waterjet technology prevents thermal distortion, maintaining the strength of titanium.

However, like any method, waterjet cutting titanium has its challenges. For instance, initial setup costs may be higher than alternatives. While the long-term benefits often outweigh these concerns, it's essential to evaluate your specific needs. With careful consideration, waterjet cutting titanium can deliver undeniable advantages for your projects.

Advantages of Waterjet Cutting Titanium in Precision Engineering

Waterjet cutting has gained traction in precision engineering, especially for titanium. This method uses high-pressure water streams combined with abrasive materials to achieve intricate cuts. Research indicates that this technique reduces material waste by up to 30%. Less waste translates to more cost-effective projects.

One significant advantage of waterjet cutting is its ability to maintain material integrity. Unlike traditional cutting methods that involve heat, waterjet cutting remains cool. This minimizes thermal distortion and maintains the properties of titanium, which can be sensitive to temperature changes. According to industry data, over 90% of engineers experienced fewer structural failures when using waterjet technology for titanium.

Precision is key in engineering. Waterjet cutting offers tolerances as tight as ±0.005 inches. This level of accuracy ensures that even the most complex designs are realized without compromising functionality. However, achieving such precision requires skilled operators. The lack of experienced technicians in some regions remains a challenge. Continuous training and adaptation are crucial for maximizing the benefits of waterjet cutting in the industrial sector.

Top 10 Benefits of Waterjet Cutting Titanium for Your Projects

| Benefit | Description |

|---|---|

| Precision Cutting | Waterjet cutting provides exceptional precision, allowing intricate designs with tight tolerances. |

| No Heat Affected Zone | The cold cutting process prevents thermal distortion, preserving the material's integrity. |

| Versatility | Suitable for various materials, including titanium, composites, and glass. |

| Minimal Waste | Efficient cutting reduces material waste, leading to cost savings. |

| Environmentally Friendly | Uses only water and garnet, with no harmful emissions or pollutants. |

| Ease of Automation | Compatible with CNC machinery, facilitating automated production processes. |

| Thickness Capability | Can cut through thick titanium sheets, accommodating various project needs. |

| Cost-Effective | Saves on labor and additional machining time due to its precision. |

| Improved Safety | Reduces hazards associated with traditional cutting methods like flames and sparks. |

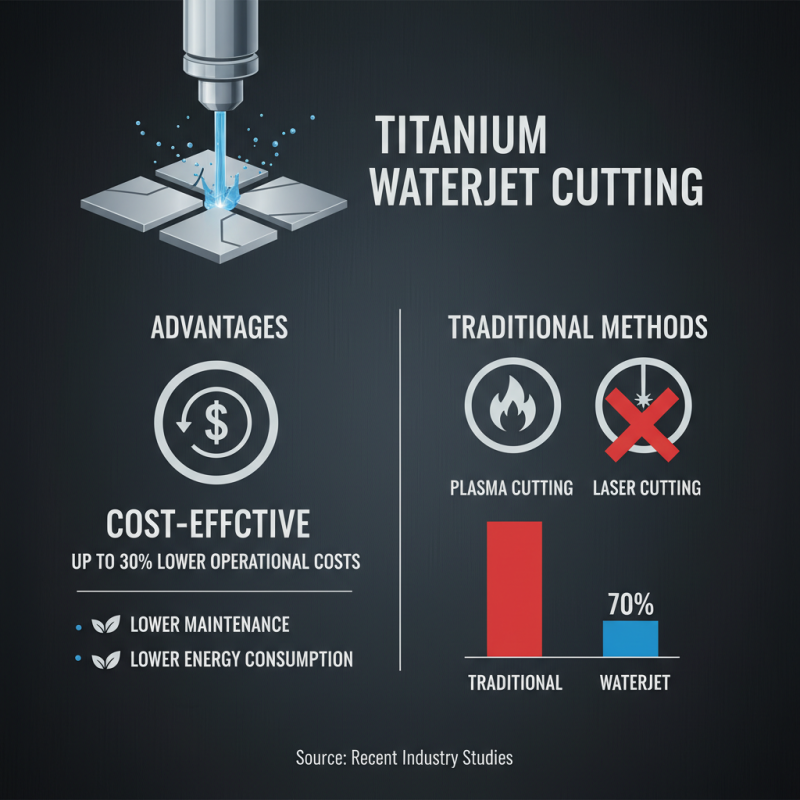

Cost-Effectiveness of Waterjet Cutting Compared to Other Methods

Waterjet cutting titanium is gaining traction in various industries. One significant advantage is its cost-effectiveness compared to traditional methods. According to recent studies, the operational costs of waterjet cutting can be up to 30% lower than plasma or laser cutting. This reduction is mainly due to lower maintenance needs and lower energy consumption.

Moreover, waterjet cutting requires no tooling changes for different thicknesses. This flexibility can lead to time savings during production. An analysis by industry experts indicates that fabricators using waterjet technology can achieve up to 20% faster turnaround times. This speed can significantly improve project deadlines and cost management.

However, achieving these benefits requires careful planning. The initial investment in waterjet equipment can be high. Some businesses may hesitate to switch, fearing hidden costs. Proper training for operators is essential to realize the efficiency of this method. Data shows that poorly managed waterjet systems can lead to increased wear and tear. Thus, understanding the balance between cost and effective use remains crucial for project success.

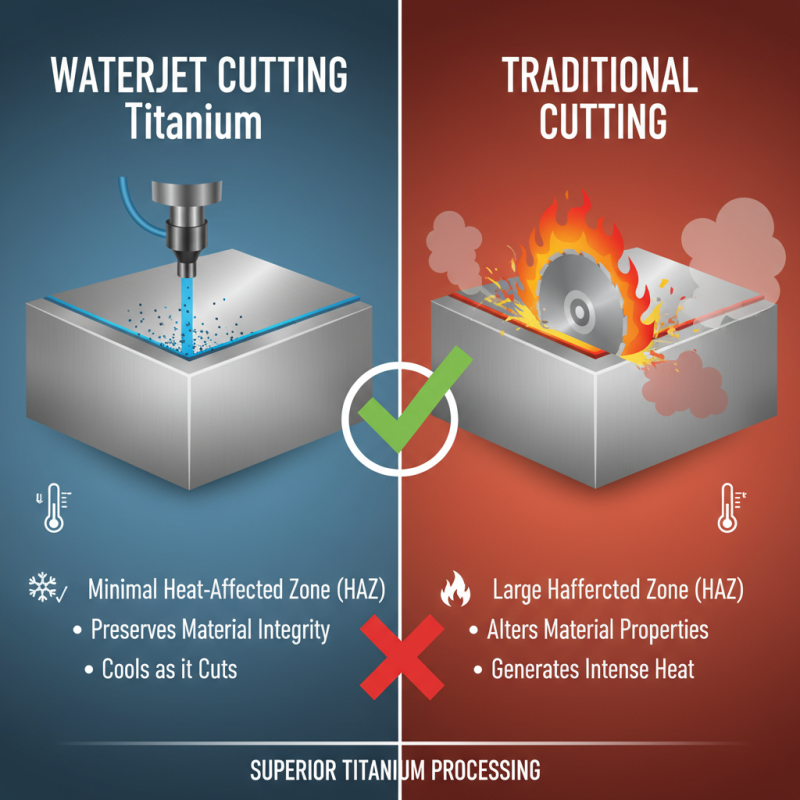

Minimal Heat Affected Zone in Titanium Waterjet Cutting

Waterjet cutting is a remarkable technique for processing titanium. One significant advantage is the minimal heat affected zone (HAZ). In traditional cutting methods, heat can alter the material's properties. This is not the case with waterjet cutting. The process uses high-pressure water mixed with abrasive materials. It cools the titanium as it cuts. This means the integrity of the titanium is preserved.

The minimal HAZ also benefits precision. Waterjet cutting allows for intricate designs without distortion. The precision is crucial for aerospace and medical applications. Even with complex shapes, there's less chance of warping or weakening the material. Therefore, projects can rely on the quality of cut titanium.

However, there are challenges. Equipment can be costly and requires expertise. Proper calibration is essential for optimal results. If misconfigured, the cut edges can become rough. This is an area to reflect on. Ensuring consistency in the process might demand adjustments and testing. Despite these challenges, the benefits of a minimal heat affected zone in titanium cutting are compelling for many applications.

Versatility of Waterjet Cutting for Complex Titanium Shapes

Waterjet cutting is revolutionizing the way we work with titanium. Its versatility allows for the creation of complex shapes with high precision. Projects that involve intricate designs benefit greatly from this technique. The waterjet can cut through thick titanium sheets without losing structural integrity.

Creating complex shapes often presents challenges. Traditional methods may struggle with the nuanced curves and angles of titanium. Waterjet cutting offers a solution, allowing for elaborate cutouts and intricate details. This capability makes it a favored choice in industries like aerospace and automotive.

Despite its advantages, waterjet cutting is not without drawbacks. Setting up the machinery can be time-consuming. The maintenance can also be a factor to consider. There can be a learning curve when operating the equipment. These challenges require careful planning but are often worth the effort for the quality results they yield.

Top 10 Benefits of Waterjet Cutting Titanium

Environmental Benefits of Using Waterjet Technology for Titanium Cutting

Waterjet cutting technology offers significant environmental advantages, particularly when it comes to titanium projects. This method uses high-pressure water to cut materials, minimizing waste. Unlike traditional cutting methods, waterjet doesn't produce harmful fumes or hazardous waste. This makes it a cleaner alternative for manufacturing.

The waterjet process also conserves energy. It requires less power than many traditional machining methods. The efficiency of water usage is another plus. Most of the water can be recycled, leading to a lower environmental footprint. However, it's essential to consider the source of the water and ensure it is sustainably managed.

Yet, there are challenges. The equipment can be costly, and not all processes achieve the same precision. Some projects might still yield greater waste than expected, due to material thickness or operator skill. Reflection on these aspects can lead to a better understanding of waterjet's real impact in titanium cutting.

Related Posts

-

What is Waterjet Cutting Titanium? Benefits, Process, and Applications Explained

-

10 Essential Tips for Effective Waterjet Cutting: Maximize Precision and Efficiency

-

Why Choosing the Right Dock Hoist is Essential for Your Marine Operations

-

Why Choose Waterjet Cutting Services in Seattle for Your Precision Needs?

-

The Ultimate Guide to Understanding Lift Docks and Their Importance in Modern Logistics

-

Water Jet Fabrication Tips for Efficient and Precise Cutting?