Top Benefits of Waterjet Cutting for Your Manufacturing Needs

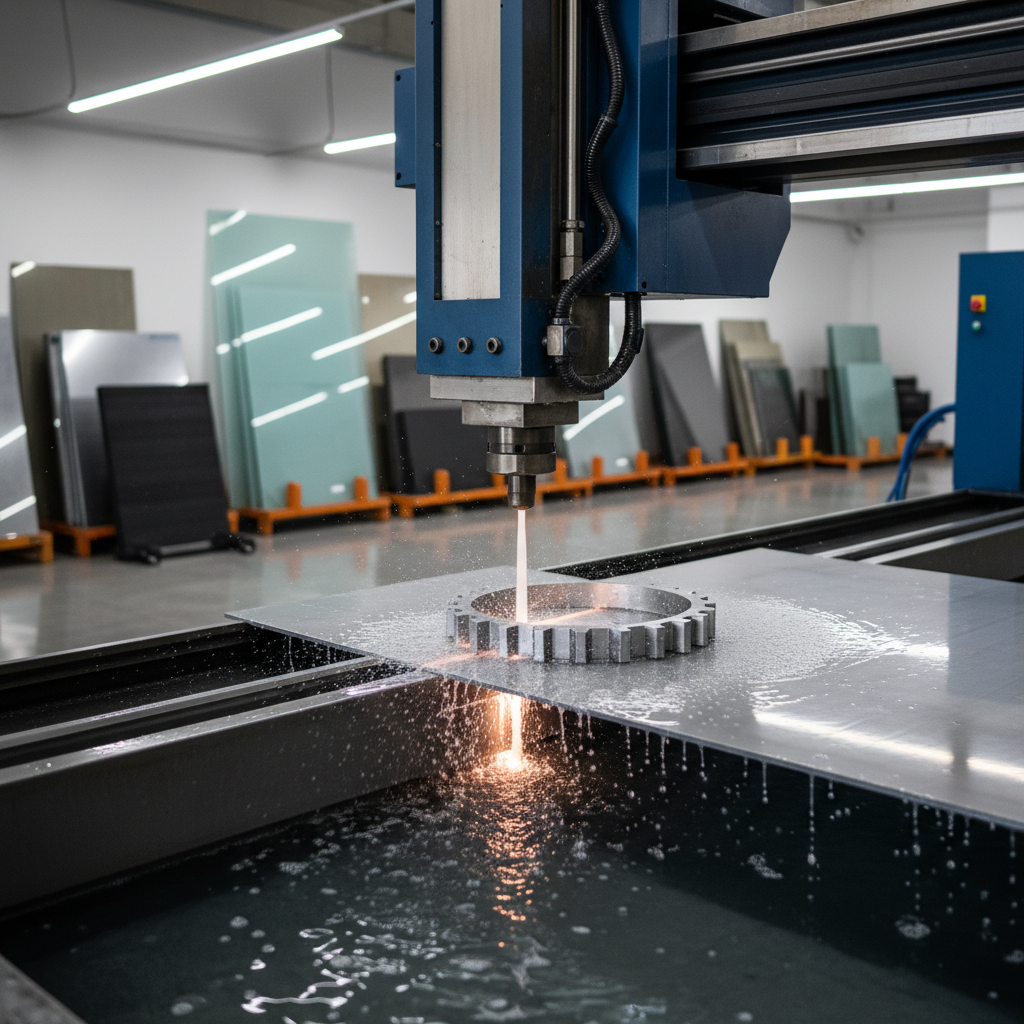

In today’s fast-paced manufacturing landscape, the need for precision and versatility in cutting methods has never been more critical. Waterjet cutting has emerged as a frontrunner in this field, offering an array of benefits that cater to diverse industrial needs. This innovative technology utilizes high-pressure water streams, often mixed with abrasives, to slice through a wide variety of materials with exceptional accuracy and minimal thermal impact. As manufacturers increasingly seek methods that enhance productivity while reducing costs, waterjet cutting stands out as a viable solution that addresses these demands effectively.

One of the most significant advantages of waterjet cutting is its ability to work with an extensive range of materials, including metals, plastics, glass, and ceramics. This adaptability allows manufacturers to optimize their operations by utilizing a single cutting method for various applications. Moreover, the precision of waterjet cutting minimizes waste and refines edge quality, leading to improved product finishes that meet stringent design specifications. As industries evolve and technological advancements continue, understanding the top benefits of waterjet cutting is essential for manufacturers aiming to stay competitive and innovate their production processes.

Advantages of Waterjet Cutting Over Traditional Methods in Manufacturing

Waterjet cutting has emerged as a leading technology in the manufacturing sector, offering a range of advantages over traditional cutting methods. Unlike laser or flame cutting, waterjet systems utilize a high-pressure jet of water, often combined with abrasive materials, to precisely cut through various materials, including metals, glass, and ceramics. According to a report by Technavio, the global waterjet cutting market is expected to grow by 3.85 billion USD from 2021 to 2025, reflecting its increasing adoption due to its versatility and efficiency.

One of the primary advantages of waterjet cutting is its ability to provide a clean edge with minimal thermal distortion. Unlike traditional methods that can produce heat-affected zones, waterjet cutting operates at ambient temperatures, preserving the integrity of the material being cut. This is particularly crucial for materials sensitive to heat, such as composites and aluminum. Additionally, a study by Research and Markets indicates that waterjet cutting can reduce waste by up to 25% compared to conventional cutting methods, making it not only a more sustainable choice but also a cost-effective one. As businesses seek to optimize their manufacturing processes, the precision and eco-friendliness of waterjet cutting continue to make it a preferred option in various industries.

Benefits of Waterjet Cutting vs Traditional Cutting Methods

Precision and Accuracy in Cutting: Statistics on Tolerance Standards

Waterjet cutting technology has revolutionized the manufacturing landscape, particularly when it comes to precision and accuracy. According to the American Waterjet Technology Association (AWTA), waterjet cutting processes can achieve tolerances as tight as ±0.005 inches. This exceptional level of precision is crucial in industries such as aerospace and automotive, where even minor discrepancies can lead to significant performance issues. Notably, a study from the National Institute of Standards and Technology (NIST) highlights that 80% of manufacturing errors can be traced back to material tolerances, stressing the importance of stringent cutting standards.

To maximize the benefits of waterjet cutting in your manufacturing processes, consider implementing these tips: First, invest in high-quality abrasive materials and regularly maintain your cutting equipment to ensure consistency in performance. Second, optimize the cutting parameters based on the material type and desired finish; this can reduce waste and improve overall efficiency. By focusing on tolerance standards and leveraging the capabilities of waterjet cutting, manufacturers can enhance their production quality and reduce operational costs in the long run.

Material Versatility: Waterjet Cutting Applications Across Industries

Waterjet cutting technology has gained traction across various industries due to its exceptional material versatility. This cutting method allows for precise cutting of a wide array of materials, including metals, plastics, glass, and even composites. The ability to work with different thicknesses and types of materials makes waterjet cutting an indispensable tool in sectors like aerospace, automotive, and architectural design. Its adaptability ensures it meets the specific needs of diverse applications, from intricate designs to robust structural elements.

In addition to versatility, the waterjet cutting process is recognized for its precision and sustainability. The absence of thermal distortion during cutting preserves the integrity of materials, ensuring that parts meet strict specifications without the need for secondary operations. Furthermore, as industries strive for environmentally friendly solutions, waterjet cutting stands out due to its efficient use of resources, producing minimal waste. This combination of factors drives the growth of the waterjet cutting machine market, highlighting its significance in modern manufacturing processes.

Environmental Benefits: Reduced Waste and Energy Consumption in Waterjet Cutting

Waterjet cutting technology presents significant environmental benefits, particularly in terms of reduced waste and energy consumption. Unlike traditional cutting methods that often create excessive scrap material, waterjet cutting utilizes a high-pressure stream of water mixed with abrasive materials to achieve precise cuts, resulting in minimal waste. This precision not only leads to cost savings for manufacturers but also aligns with sustainable practices by maximizing material usage.

Moreover, waterjet cutting is energy-efficient. The process requires less energy compared to machining methods that involve heating materials or extensive mechanical power. This lower energy consumption directly contributes to a reduced carbon footprint for manufacturing operations. Tips for manufacturers looking to optimize their waterjet cutting processes include regularly maintaining equipment to ensure efficiency and exploring batch processing to minimize energy use during operation. Proper training of operators can also enhance both the performance and the environmental benefits of the cutting process.

By adopting waterjet cutting, businesses not only improve their manufacturing efficiencies but also participate actively in environmental sustainability. This technology offers a compelling solution for organizations seeking to reduce their ecological impact while maintaining high standards of production quality.

Cost-Effectiveness: Long-Term Savings with Waterjet Cutting Technology

Waterjet cutting technology has emerged as a cost-effective solution in modern manufacturing, offering significant long-term savings to businesses across various industries. According to a study by The Fabricator, waterjet cutting can reduce material waste by up to 80% compared to traditional cutting methods, ultimately leading to lower material costs for manufacturers. This efficiency is particularly beneficial for industries that deal with expensive materials, such as aerospace and automotive, where every inch of material saved directly translates into substantial cost reductions.

In addition to material savings, waterjet cutting systems typically require less energy consumption compared to other cutting technologies, such as plasma or laser cutting. The U.S. Department of Energy indicates that waterjet cutting can operate with up to 50% less energy, significantly lowering operational costs over time. Furthermore, the minimal need for tool changes or maintenance translates to reduced downtime, allowing manufacturers to maximize production efficiency. By adopting waterjet cutting technology, companies can not only cut costs but also enhance their competitive edge in the market by improving efficiency and reducing overhead expenses.

Related Posts

-

Understanding the Benefits of Jet Cut Technology in Modern Manufacturing

-

Why Choose Waterjet Cutting Services in Seattle for Your Precision Needs?

-

The Future of Cutting Technologies Exploring the Benefits of Water Jet Abrasive Systems

-

The Future of Precision Manufacturing with Waterjet Cutting Technology in Utah

-

The Ultimate Guide to Understanding How a Water Jet Head Transforms Industrial Cutting

-

Top 10 Waterjet Cutting Parts for Precision Engineering Applications