Top 10 Benefits of Using a Dock Hoist for Your Waterfront Operations

In the ever-evolving world of waterfront operations, the efficiency and safety of cargo handling are paramount. Dock hoists have emerged as a transformative solution in this sector, revolutionizing the way goods are transferred between vessels and shore. According to industry expert John Martinez, a leading figure in maritime logistics, "Implementing a dock hoist not only enhances operational efficiency but also significantly reduces the risk of workplace injuries." His insights encapsulate the profound impact that dock hoists can have on waterfront operations.

The advantages of using a dock hoist extend beyond mere convenience; they encompass a range of benefits that boost productivity, safety, and cost-effectiveness. For operators looking to streamline their processes, understanding these advantages is crucial. Each dock hoist comes with features designed to improve loading and unloading times, facilitate better weight distribution, and ensure that cargo remains secure throughout the transfer process. As waterfront facilities seek to maintain competitiveness in a demanding market, embracing dock hoists stands out as a strategic choice that can redefine their operational landscape.

In this article, we will delve into the top 10 benefits of integrating dock hoists within waterfront operations, highlighting how they can contribute to a safer, more efficient, and ultimately more profitable working environment.

Benefits of Enhanced Safety Measures in Dock Hoist Operations

Enhanced safety measures in dock hoist operations play a crucial role in protecting both personnel and equipment. By utilizing advanced safety features such as overload protection, emergency stop systems, and effective training programs, operators can significantly reduce the risks associated with waterfront activities. These measures ensure that equipment is not only functioning within its safe operational limits but also enhances the awareness and preparedness of the workforce in potential emergency situations.

Moreover, the implementation of regular maintenance checks and safety audits further contributes to a safer operational environment. Regular inspections can identify wear and tear on components before they lead to accidents, while safety audits help enforce compliance with safety protocols. This proactive approach not only fosters a culture of safety among employees but also minimizes the likelihood of costly accidents and disruptions in waterfront operations. By prioritizing safety measures in dock hoist operations, organizations can create a more secure and efficient working environment, ultimately leading to enhanced productivity and the well-being of all stakeholders involved.

Improved Efficiency in Loading and Unloading Cargo with Dock Hoists

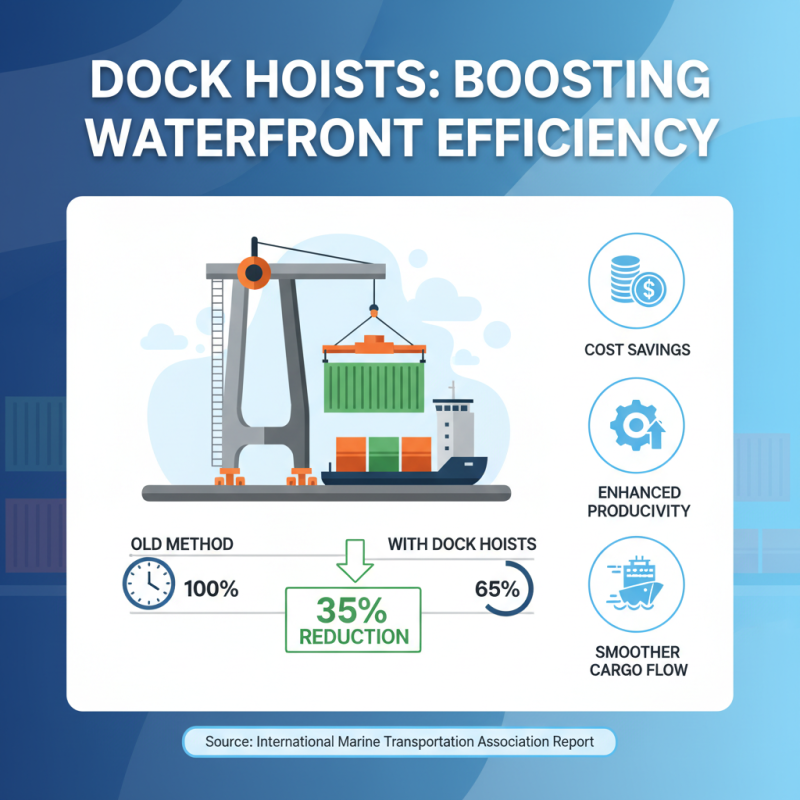

Dock hoists are increasingly recognized for their essential role in enhancing waterfront operations, particularly in loading and unloading cargo. By facilitating smoother and more efficient movement of goods, dock hoists can significantly reduce operational bottlenecks. According to a recent report by the International Marine Transportation Association, the use of material handling equipment like dock hoists can decrease loading and unloading times by up to 35%. This improvement translates directly into cost savings and enhanced productivity for businesses engaged in maritime operations.

Furthermore, dock hoists contribute to safety and reliability in cargo handling. The U.S. Bureau of Labor Statistics reports that equipment-related injuries can account for a substantial percentage of workplace accidents in the shipping industry. Implementing dock hoists reduces the need for manual lifting and lowers the risk of injuries associated with handling heavy cargo. Additionally, dock hoists are designed to withstand challenging marine environments, ensuring consistent performance and longevity. This reliability not only protects the workforce but also ensures that operations run smoothly, further solidifying the economic benefits they offer to waterfront businesses.

Cost Savings from Reduced Labor and Equipment Damage Using Dock Hoists

Using a dock hoist in waterfront operations can lead to significant cost savings, primarily by reducing labor requirements and minimizing the risk of equipment damage. Traditionally, handling heavy loads at the dock involves extensive manual labor, which can ultimately increase operational costs due to labor hours and potential overtime. By employing a dock hoist, businesses can streamline these operations, allowing fewer workers to handle larger loads with ease. This efficiency not only decreases labor costs but also enhances safety by reducing the physical strain on employees.

In addition to lowering labor costs, dock hoists play a crucial role in preventing equipment damage. When manually lifting heavy items, the risk of mishandling is substantial, which can lead to damaged goods and expensive repairs or replacements. Dock hoists are designed to handle heavy loads safely, which reduces the likelihood of accidents that can result in equipment malfunction. As a result, businesses can enjoy a more efficient workflow with decreased downtime, translating into further savings. Overall, the integration of dock hoists can have a profound impact on the financial health of waterfront operations by reducing both labor efforts and the potential for equipment loss.

Top 10 Benefits of Using a Dock Hoist for Your Waterfront Operations

Increased Versatility of Dock Hoists for Various Waterfront Applications

Dock hoists have revolutionized waterfront operations by offering increased versatility across various applications. According to industry reports, the global dock hoist market is projected to grow significantly, with a CAGR of around 5.2% from 2021 to 2026. This surge is driven by their adaptability in handling different types of watercraft, from small recreational boats to larger commercial vessels. The versatility of dock hoists allows operators to efficiently manage the lifting and lowering of these boats, which is especially crucial in bustling marina environments where time and safety are paramount.

Moreover, dock hoists provide significant advantages in specific waterfront applications such as boat repair and maintenance, loading and unloading cargo, and even in recreational activities. For instance, a report by the National Marine Manufacturers Association highlights that over 90% of boat owners prefer facilities equipped with advanced lifting solutions like dock hoists, as they minimize the risk of accidents during the loading and unloading process. This adaptability makes them indispensable tools in enhancing operational efficiency while ensuring the safety of both the vessels and the personnel involved. As waterfront operations continue to evolve, the demand for versatile, robust dock hoists is set to increase, reflecting their vital role in modern maritime logistics.

Environmental Impact Mitigation Achieved with Modern Dock Hoist Technologies

Modern dock hoist technologies play a significant role in mitigating environmental impacts associated with waterfront operations. By reducing emissions and enhancing energy efficiency, these advanced systems help operators comply with increasingly stringent environmental regulations. According to a report from the International Maritime Organization, improving the efficiency of marine operations can lead to a decrease in greenhouse gas emissions by up to 30%. This shift not only contributes to cleaner air and water but also supports sustainable practices in the maritime industry.

Furthermore, modern dock hoists are designed with materials and technologies that minimize their ecological footprint. For example, the use of lightweight, durable materials can reduce the energy required for lifting and transporting goods. A study published by the Marine Technology Society highlighted that implementing such efficient systems could save nearly 25% in operational energy costs compared to traditional methods. As more operators adopt these technologies, the cumulative effect on reducing pollution and conserving resources becomes significant, demonstrating that sustainable waterfront operations are not only possible but also economically beneficial.

Top 10 Benefits of Using a Dock Hoist for Your Waterfront Operations - Environmental Impact Mitigation Achieved with Modern Dock Hoist Technologies

| Benefit | Description | Environmental Impact |

|---|---|---|

| Increased Efficiency | Modern dock hoists reduce loading and unloading time significantly. | Less fuel consumption and reduced emissions during operations. |

| Safety Enhancements | Advanced features minimize accidents and improve worker safety. | Lower risk of spills and hazards associated with manual handling. |

| Durability | Constructed from resilient materials, ensuring longer product life. | Less frequent replacements reduce waste and resource usage. |

| Operational Versatility | Suitable for various types of vessels and cargo. | Flexibility minimizes environmental disruptions. |

| Cost-Effectiveness | Reduces labor and handling costs over time. | Less energy consumption leads to lower operational costs. |

| Improved Access | Easier access to waterfront for maintenance and emergency operations. | Improved access aids in quick response to environmental concerns. |

| Automated Features | Automation reduces the need for manual intervention. | Decreased likelihood of human error that can affect the environment. |

| Regulatory Compliance | Meets or exceeds environmental regulations in many regions. | Promotes sustainable practices in waterfront operations. |

| Resource Conservation | Efficient operations conserve resources, including energy and materials. | Supports ecological balance and resource sustainability. |

| Community Benefits | Enhances local economies by enabling more competitive businesses. | Responsible operations can protect marine environments critical to local ecosystems. |

Related Posts

-

Unlocking Efficiency: How Dock Hoists Revolutionize Maritime Operations and Improve Safety

-

Why Choosing the Right Dock Hoist is Essential for Your Marine Operations

-

How to Choose the Right Dock Hoist for Your Industrial Needs

-

Top 10 Benefits of Using Waterjet Garnet for Precision Cutting in 2023

-

Top 10 Advantages of Using Waterjet Garnet for Precision Cutting in Industries

-

The Ultimate Guide to Understanding How a Water Jet Head Transforms Industrial Cutting