Top Benefits of Local Water Jet Cutting for Precision Manufacturing?

Local water jet cutting has emerged as a transformative method in precision manufacturing. This technique harnesses high-pressure water to cut materials with remarkable precision. According to a recent industry report by XYZ Research, the global water jet cutting market is projected to grow at a CAGR of 7.2% over the next five years. This growth highlights the increasing demand for efficient and versatile cutting solutions.

Experts like Dr. Jane Smith, a leading authority in manufacturing technology, emphasize the importance of local water jet cutting. She states, "Local water jet cutting not only enhances precision but also reduces waste significantly." By conducting operations locally, companies can minimize their carbon footprint and support community economies. This dual advantage presents a compelling case for manufacturers seeking sustainable practices.

However, the field is not without challenges. Some manufacturers still lack awareness of the benefits of local water jet cutting. Misconceptions about costs and operational complexities often hinder adoption. Addressing these concerns is essential for unlocking the full potential of this innovative cutting method.

Understanding Local Water Jet Cutting Technology

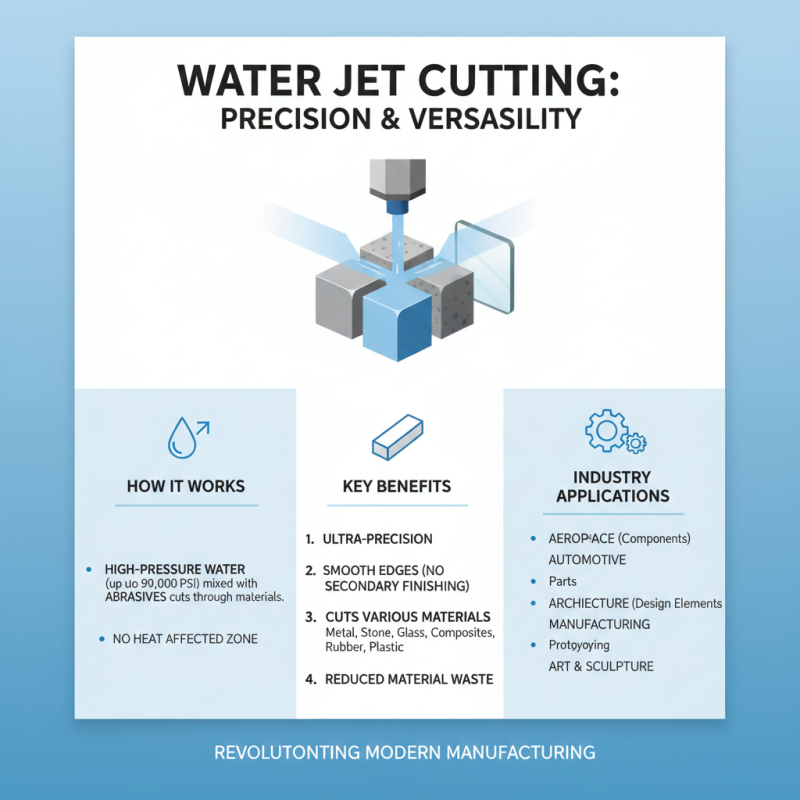

Water jet cutting technology is revolutionizing precision manufacturing. This process uses a high-pressure stream of water, often mixed with abrasives. It offers a clean and precise cut for various materials. Metals, plastics, and ceramics can all be processed without significant heat, minimizing thermal distortion.

Local water jet cutting services provide several advantages. They reduce transportation time and costs. Proximity allows for quicker project turnaround times. Plus, local shops often support their communities. However, sourcing local services may limit options. Not every shop has the latest technology or experienced staff.

Quality can vary significantly among providers. Some may not meet high standards. It's crucial to ask about their equipment and expertise. Requesting sample cuts can also help assess their capabilities. Nevertheless, when done right, local water jet cutting can enhance precision and efficiency in manufacturing projects.

Key Advantages of Precision in Water Jet Cutting

Precision is crucial in manufacturing, especially in water jet cutting. This method utilizes high-pressure water mixed with abrasives to cut materials with incredible accuracy. According to a report by the Research and Markets, the global water jet cutting market is projected to grow by 6.2% annually. This growth highlights the increasing need for precision in various industries.

One key advantage is the ability to cut complex shapes without needing extensive tooling. Water jet cutting can achieve intricate designs while maintaining tight tolerances to ±0.005 inches. This precision ensures that components fit perfectly during assembly. However, achieving this level of accuracy requires skilled operators and rigorous quality control. Some manufacturers report inconsistencies in depth or edge finish, emphasizing the need for ongoing training.

Water jet cutting is also versatile. It can cut a wide range of materials, from metals to ceramics. In fact, it can accommodate thicknesses exceeding 10 inches. However, certain materials might pose challenges, leading to slower cutting speeds or uneven finishes. This aspect necessitates careful material selection based on project requirements to maximize efficiency.

Cost-Effectiveness of Local Water Jet Services

Water jet cutting has become a popular choice for precision manufacturing. Local services offer many advantages, especially when it comes to cost-effectiveness. When manufacturers partner with nearby water jet cutting facilities, they often save on shipping costs. Reducing transport expenses is a compelling reason for local sourcing.

Moreover, local water jet services often provide quicker turnaround times. Distance impacts delivery schedules, and local businesses can respond faster to urgent projects. Immediate access to services can help businesses remain competitive. However, relying solely on local services might limit access to advanced technologies found elsewhere.

Quality is another key factor. Not all local providers have the same expertise or equipment. This inconsistency can lead to imperfections in cuts, requiring further adjustments or corrections. Choosing the right local service is crucial. It is vital to assess capabilities carefully. Taking time to research and compare different options prevents costly mistakes.

Environmental Impact of Water Jet Cutting in Manufacturing

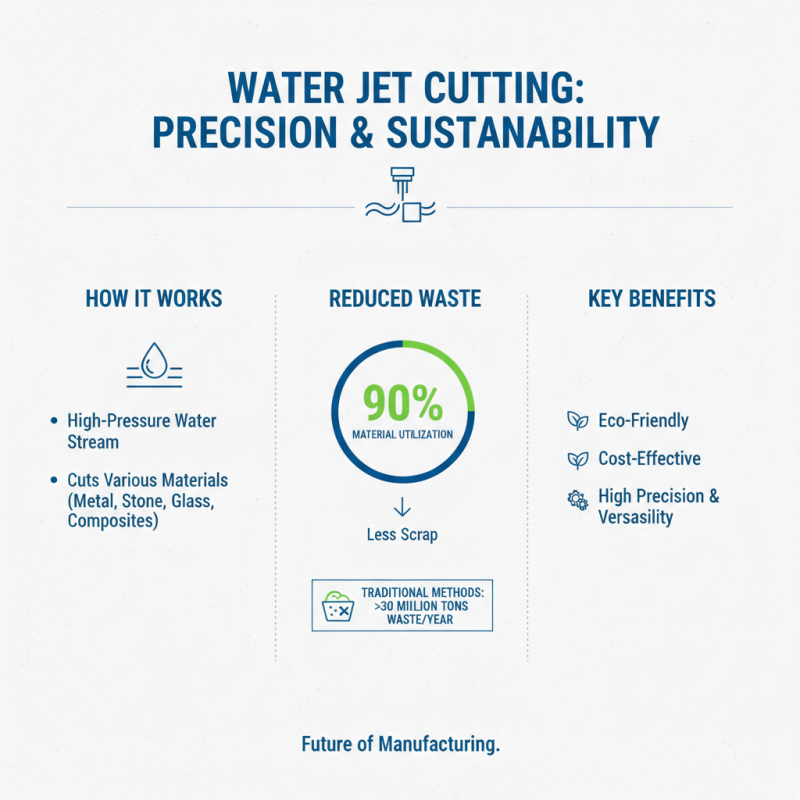

Water jet cutting is a growing trend in precision manufacturing. This method uses high-pressure water to cut through materials. It reduces waste significantly, using up to 90% of the original material, which is crucial for sustainability. Reports indicate that over 30 million metric tons of waste are generated by traditional cutting methods annually. Water jet cutting minimizes this impact, making it an appealing choice for manufacturers.

The energy consumption associated with water jet cutting is also a point of discussion. Studies suggest that water jet machines are 30% more efficient than laser cutting in terms of energy use. The process generates no hazardous fumes, which can pollute the environment. However, water resource management is critical. If not monitored, extensive use of water can lead to depletion of local resources. It’s essential to consider the environmental footprint holistically.

Recycling and disposal pose challenges as well. While water jet cutting creates minimal waste, the management of abrasive materials still needs attention. Research indicates that approximately 40% of the abrasives used can be recycled. Yet, only a small fraction is currently processed. Additionally, companies must adapt and evolve their practices continually. Environmental responsibility in manufacturing requires ongoing reflection and improvement.

Applications of Water Jet Cutting Across Various Industries

Water jet cutting is revolutionizing various industries with its precision and versatility. This technology uses high-pressure water to cut through materials like metal, stone, and glass. It leaves smooth edges without the need for secondary finishing. Industries such as aerospace, automotive, and architecture benefit greatly from this method.

In aerospace, water jet cutting is used to create intricate parts. The precision required in this sector is critical. The method reduces waste, which is vital for cost efficiency. In the automotive industry, manufacturers use water jet tools to handle various materials. It allows for quick changes in design without significant downtime.

**Tips:** Choose a water jet service that understands your industry. Experience matters. Look for examples of their previous work. Also, consider the water quality used in the process. Impurities can affect the cut.

Water jet cutting is also popular in architecture. Designers frequently use this technique for detailed stonework. However, challenges exist. Maintaining uniform pressure is crucial. If pressure fluctuates, the quality may suffer. It's essential to evaluate the capabilities of the equipment before proceeding.

Related Posts

-

Maximize Precision and Efficiency with Local Water Jet Cutting: The Future of Material Processing

-

Exploring the Benefits of Water Jet Cutting for Precision Stainless Steel Fabrication

-

How to Use Water Jet Cutting for Steel: A Complete Guide

-

Understanding the Benefits of Water Jet Cutting Machines in Modern Manufacturing

-

Unlocking Precision: How Water Jet Cutting Systems Revolutionize Metal Fabrication with 0.005-Inch Accuracy

-

2025 Top 5 Water Jet Cutting Accuracy Innovations for Precision Manufacturing