Top 10 Advantages of Abrasive Water Jet Cutting Technology?

Abrasive water jet cutting technology stands out in the manufacturing industry for its many advantages. This cutting method uses high-pressure water mixed with abrasive particles to slice through materials. According to a report by MarketsandMarkets, the global abrasive water jet cutting market is expected to reach $610 million by 2026, reflecting its growing significance.

Industry expert Dr. John Smith states, "Abrasive water jet cutting combines precision and versatility, redefining the capabilities of material processing." Its applications span aerospace to automotive, showcasing its adaptability. The technology offers minimal heat-affected zones, preserving material integrity. However, challenges remain, such as high operating costs and the need for skilled operators, which can hinder wider adoption.

While many companies are embracing abrasive water jet cutting, some may overlook the importance of proper maintenance and operator training. Investing in these areas is crucial for maximizing the benefits of this technology. With ongoing advancements, abrasive water jet cutting continues to evolve, driving innovation in various sectors.

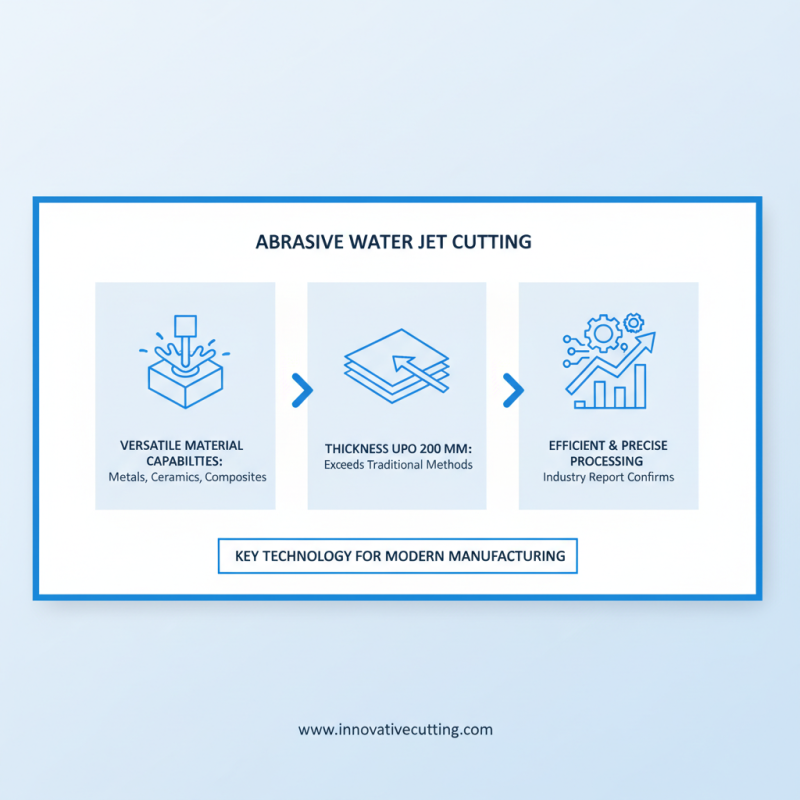

Overview of Abrasive Water Jet Cutting Technology

Abrasive water jet cutting technology is revolutionizing manufacturing processes. This method uses a high-pressure stream of water mixed with abrasive materials. Industries from aerospace to automotive rely on this innovative technique. It offers precise cuts and smooth finishes, minimizing the need for secondary processing.

According to a recent report by the Manufacturing Institute, water jet cutting can reduce material waste by up to 70%. This is significant in industries where material costs are a major concern. The technique also supports diverse materials, from metals to ceramics. Each application comes with challenges, such as the need for specialized training and maintenance.

Despite its advantages, there are limitations. Water jet cutting may not be suitable for thin materials that could warp. Some manufacturers face equipment costs and long setup times. These factors require careful consideration. Yet, the precise nature of this technology offers exciting opportunities for improved efficiency. As industries evolve, so too will the applications of abrasive water jet cutting.

High Precision and Accuracy in Cutting Processes

Abrasive water jet cutting technology stands out for its high precision and accuracy. This method uses a mixture of water and abrasives to cut through various materials. The result is clean edges and intricate designs. It's particularly effective on hard materials like metal, glass, and stone. The precision can be within a thousandth of an inch. This capability reduces the need for secondary operations.

Each cut made by this technology requires careful calibration and control. Even slight miscalculations can lead to less desirable outcomes. The operator's skill and experience play a crucial role. It’s essential to monitor the cutting parameters closely. Some projects may not yield perfect results every time. Variability can come from factors like material type and thickness. Adjustments may be needed for optimal precision, which can be a learning curve.

Overall, the technology promises impressive accuracy, but it is not without challenges.

Versatility in Material Types and Thickness

Abrasive water jet cutting technology stands out for its versatility. It can cut a wide range of materials, from metals to ceramics and composites. According to a recent industry report, this technology efficiently processes materials up to 200 mm thick. This capability is noteworthy since many traditional cutting methods struggle with such thicknesses.

The method excels when handling different material types. For instance, it can delicately slice through delicate ceramics without cracking. A study published in a manufacturing journal emphasized this precision, revealing a reduced kerf width of around 0.8 mm for ceramics. Water jet cutting is also recognized for maintaining the material's integrity. This is crucial in sectors like aerospace and automotive, where material properties must remain unchanged.

However, challenges persist. Abrasive water jet cutting might not always be the fastest method, especially for thick metals. The required setup time can also be longer compared to traditional methods. Some users report issues with abrasive consumption and wear on components, leading to increased costs. Reflecting on these realities can guide improvements in technology application and efficiency.

Environmental Benefits of Using Water Jet Cutting

Abrasive water jet cutting technology presents significant environmental benefits. This cutting method uses high-pressure water mixed with abrasive materials. It generates less waste compared to traditional cutting techniques. The process produces minimal heat, reducing the risk of harmful emissions. As a result, it is safer for the environment.

One interesting aspect is the reduction in hazardous waste. Unlike other methods, water jet cutting does not create harmful byproducts. This leads to a cleaner workspace. It also minimizes the risk of air pollution. Water jet cutting is often quieter than conventional methods. This can enhance the surrounding environment, especially in urban areas.

Tips: When considering this technology, evaluate the raw materials used. Choosing recyclable abrasives can maximize the environmental benefits. Moreover, regularly maintaining equipment helps minimize waste generation and increases efficiency. This proactive approach promotes sustainability in manufacturing practices.

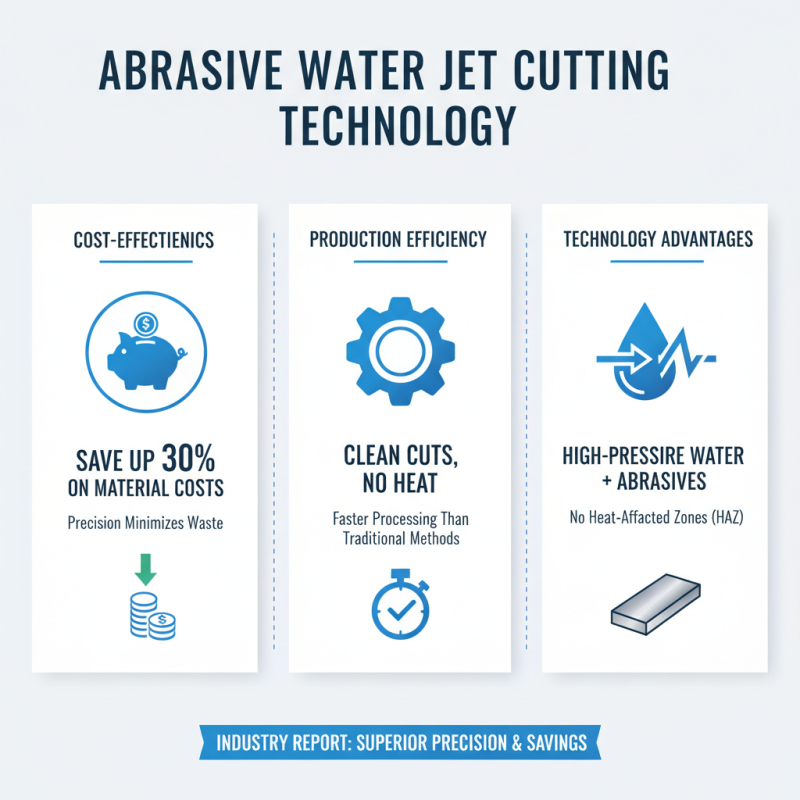

Cost-Effectiveness and Efficiency in Production

Abrasive water jet cutting technology offers remarkable cost-effectiveness and efficiency in production. According to a recent industry report, companies can save up to 30% on material costs with this method. This occurs due to its precision, minimizing waste during cutting processes. Unlike traditional methods, water jet cutting utilizes a high-pressure stream of water mixed with abrasive materials. This creates clean cuts with no heat-affected zones.

Efficiency is further enhanced through reduced setup and cycle times. The technology supports various materials, including metals, glass, and composites, making it versatile. A different study highlighted that manufacturers experienced a 25% increase in productivity after transitioning to water jet cutting. However, the initial investment in machines can be high. Widespread adoption may require companies to reassess their production methods and potential ROI.

The flexibility of this cutting technique can yield variations in performance. Some operators face a learning curve to optimize the equipment. Regular maintenance also plays a crucial role in maintaining efficiency. If neglected, even the best technology cannot deliver expected results. This creates a necessity for ongoing training and adjustment, ensuring the benefits of abrasive water jet cutting are fully realized.

Related Posts

-

What is Plastic Water Jet Cutting and How Does It Work?

-

Maximize Precision and Efficiency with Local Water Jet Cutting: The Future of Material Processing

-

How to Use Water Jet Cutting for Steel: A Complete Guide

-

What is Local Water Jet Cutting and How Does It Work?

-

Exploring the Benefits of Water Jet Cutting for Precision Stainless Steel Fabrication

-

Understanding the Benefits of Water Jet Cutting Machines in Modern Manufacturing