Top Advantages of 3D Waterjet Cutting for Modern Manufacturing?

In today's fast-paced manufacturing world, 3D waterjet cutting stands out as a revolutionary technique. Experts, like Dr. Emma Choi, emphasize its potential, stating, "3D waterjet cutting transforms precision machining." This method utilizes high-pressure water mixed with abrasive materials to cut through various materials with incredible accuracy.

The advantages of 3D waterjet cutting are numerous. It eliminates the need for heat, preserving the integrity of sensitive materials. This means less distortion and a cleaner finish. Many industries benefit, from aerospace to automotive manufacturing. The flexibility of 3D waterjet cutting allows for intricate designs that traditional methods struggle to achieve.

However, challenges remain. The initial setup costs can be significant, and operational expertise is essential. As companies strive for efficiency, the learning curve can present obstacles. Yet, as manufacturers explore the capabilities of 3D waterjet cutting, the potential for innovation appears limitless.

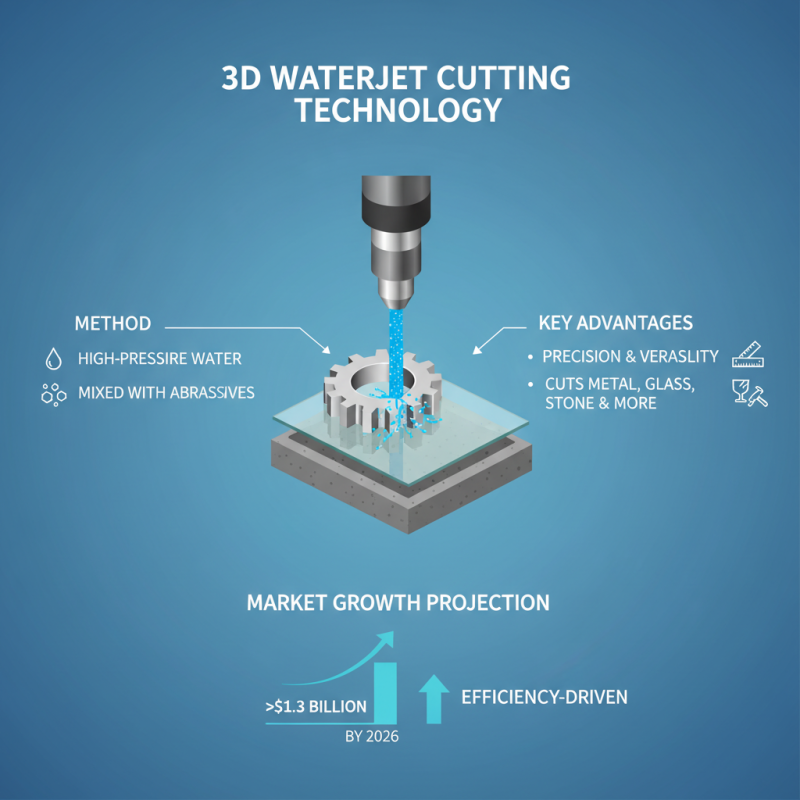

Understanding 3D Waterjet Cutting Technology in Manufacturing

3D waterjet cutting technology is revolutionizing modern manufacturing. This method uses high-pressure water mixed with abrasives to cut materials. It excels in precision and versatility, making it suitable for various materials, including metal, glass, and stone. Reports indicate that the market for waterjet cutting is projected to grow significantly. By 2026, it could reach over $1.3 billion, driven by its efficiency.

One major advantage of this technology is its ability to cut complex shapes without thermal distortion. This is crucial for industries like aerospace and automotive. Traditional cutting methods can introduce heat, causing material warping. A study found that 3D waterjet cutting reduces waste by up to 30%. Less waste means lower costs and a smaller environmental impact.

However, there are challenges. Maintenance of waterjet systems can be demanding. Abrasives need regular replenishing, adding to operational costs. Moreover, the technology requires skilled operators. As it becomes more widespread, training programs must keep pace. These factors warrant careful consideration in manufacturing strategies.

Key Benefits of Using 3D Waterjet Cutting for Material Processing

3D waterjet cutting offers numerous benefits for modern manufacturing. One of the key advantages is its versatility. This technology can process a wide range of materials, including metals, composites, and ceramics. It cuts without generating heat, which preserves the integrity of the material. The precision of 3D waterjet cutting also leads to less wastage. This saves both material costs and time during production.

When considering 3D waterjet cutting, it’s important to remember that not all materials are suitable. Some extremely hard materials may require more powerful machinery. Operators must also ensure that they are trained properly. Misjudgments can lead to costly mistakes.

Tips: Ensure to test the setup before starting any job. This will help identify issues early. Regular maintenance of the equipment minimizes breakdowns. Always review completed cuts to refine the process. Continual learning is crucial for effective use of technology.

Applications of 3D Waterjet Cutting Across Various Industries

3D waterjet cutting is revolutionizing various industries with its precision and versatility. This technology utilizes high-pressure water mixed with abrasive materials. It effectively cuts through diverse materials like metals, glass, and stone. The ability to create intricate designs without thermal distortion is a significant advantage. This feature is essential in aerospace and automotive sectors.

In the architecture and construction industries, 3D waterjet cutting delivers detailed patterns and customized shapes. The precision allows for unique designs, enhancing both aesthetics and functionality. In the art world, artists appreciate the technology for its ability to create complex sculptures.

However, the process isn't without challenges. Setting up and calibrating the machines can require specialized skills. Sometimes, the cost of equipment can be a barrier for smaller businesses. Reflecting on these aspects can lead to improvements in adoption and efficiency. Overall, the broad application potential makes 3D waterjet cutting a valuable tool in modern manufacturing.

Top Advantages of 3D Waterjet Cutting for Modern Manufacturing

This chart illustrates the top advantages of 3D waterjet cutting as a modern manufacturing technique. The advantages include high precision cutting, material versatility, the absence of heat affected zones, eco-friendliness, and cost efficiency. The data represents the perceived effectiveness of each advantage on a scale of 0 to 100%.

Comparison of 3D Waterjet Cutting with Traditional Cutting Methods

3D waterjet cutting is revolutionizing modern manufacturing. Unlike traditional methods, it uses high-pressure water mixed with abrasives. This technique minimizes heat-affected zones, preserving material integrity. Traditional cutting often leads to warping or stress in materials.

Precision is another vital aspect. Waterjet cutting produces cleaner edges than many traditional methods. This reduces the need for post-processing. However, it can be slower for thick materials. Each project may require careful consideration of the cutting speed, thickness, and material type.

Cost-efficiency is a noteworthy point. While the initial setup for waterjet cutting may be higher, it can save on material waste. Traditional cutting might necessitate more discarded pieces. Waterjet technology is generally quieter too, which improves the working environment. However, some operators find the machines complex and may struggle with training.

Top Advantages of 3D Waterjet Cutting for Modern Manufacturing

| Feature | 3D Waterjet Cutting | Traditional Cutting Methods |

|---|---|---|

| Material Versatility | Excellent - Can cut a wide range of materials | Limited - Best for specific materials |

| Precision | High precision with smooth edges | Moderate precision, often requires post-processing |

| Heat Affected Zone | Minimal - No thermal distortion | High - Can cause warping and changes in material properties |

| Setup Time | Quick setup and adjustments | Longer setup time, depending on tooling |

| Waste Production | Low - Efficient material usage | Higher - Often results in more scrap |

| Safety | Generally safer, with low risk of sparks | Higher risk due to sparks and heat |

| Cost Efficiency | Higher initial investment, but lower overall costs | Lower initial costs, but potentially higher in the long term |

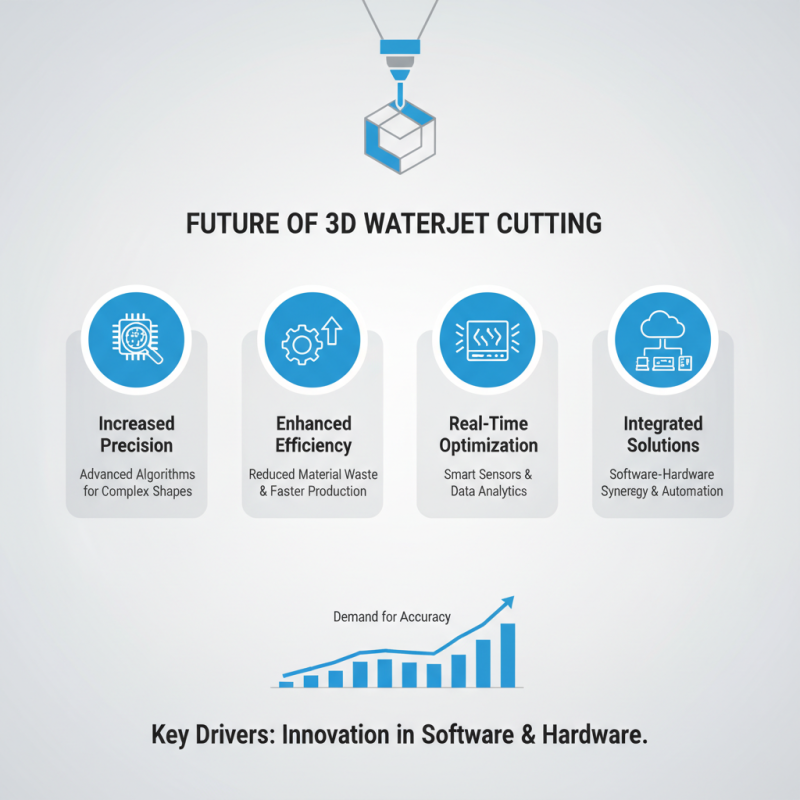

Future Trends and Innovations in 3D Waterjet Cutting Technology

The future of 3D waterjet cutting technology holds exciting possibilities. As the demand for precision continues to rise, innovations in software and hardware will play a key role. Industries are looking for ways to enhance efficiency and reduce waste. New algorithms may significantly improve the cutting accuracy of complex shapes. Enhanced sensors could provide real-time data, making cuts more precise.

Meanwhile, advancements in automation could revolutionize the workflow. Imagine machines that adjust their cutting paths instantaneously based on material thickness. This could minimize errors, but it's not flawless. Over-reliance on technology might lead to oversight of human craftsmanship. The balance between automated solutions and skilled labor will need careful consideration.

Moreover, eco-friendly practices are becoming essential. Trends indicate a shift toward greener waterjet cutting processes. Technologies that recycle water and minimize energy consumption are gaining traction. However, realizing this dream presents challenges. Implementing these innovations requires investment and adaptation. As manufacturers strive for sustainability, they must also address potential operational hiccups. What's clear is that the journey is fraught with both promise and complexities.

Related Posts

-

Why is Waterjet Cutting the Best Choice for Precision Manufacturing

-

Why Choose Waterjet Cutting Services in Seattle for Your Precision Needs?

-

Top Tips for Maintaining Waterjet Cutting Parts for Optimal Performance

-

The Future of Precision Manufacturing with Waterjet Cutting Technology in Utah

-

Understanding the Benefits of Jet Cut Technology in Modern Manufacturing

-

2026 Best Waterjet Cutting Aluminum Techniques for Precision Manufacturing?