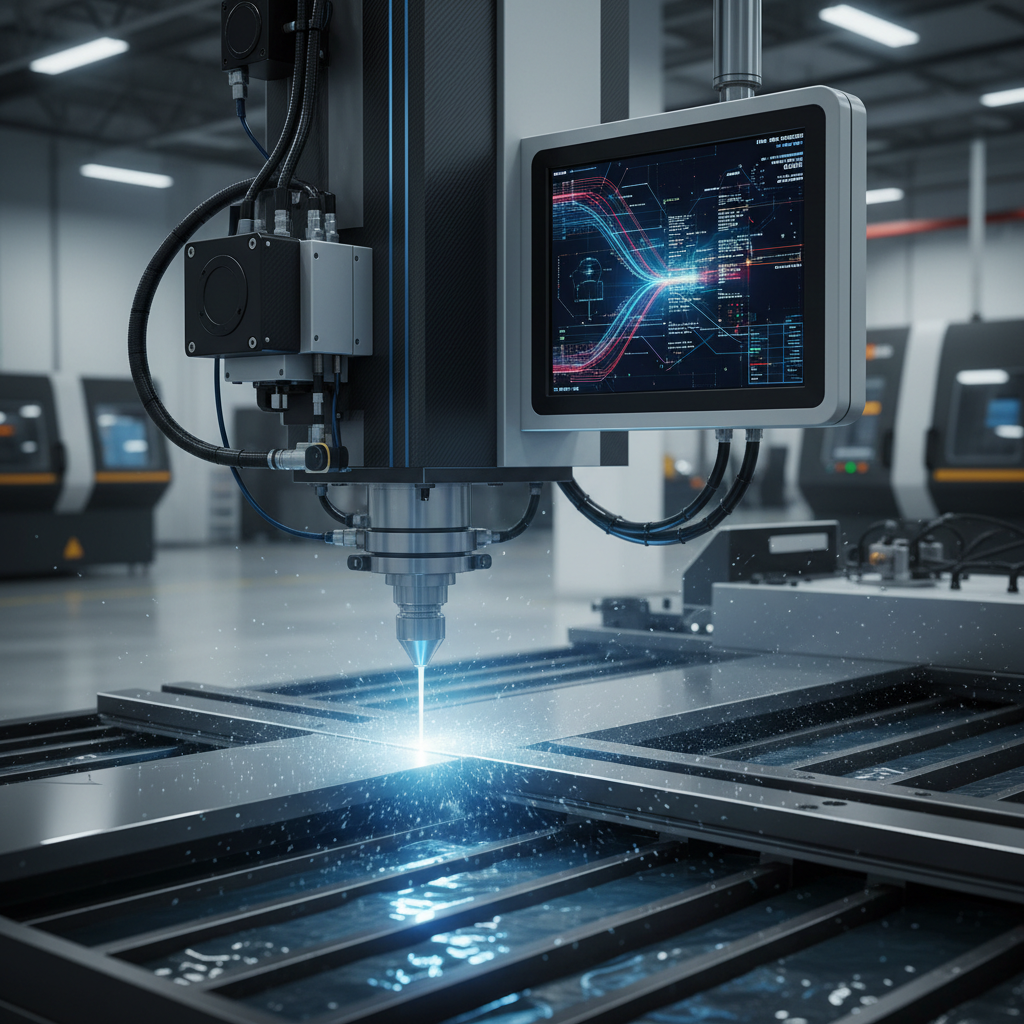

2025 Top 5 Water Jet Cutting Accuracy Innovations for Precision Manufacturing

In the rapidly evolving landscape of precision manufacturing, water jet cutting accuracy stands out as a pivotal factor influencing both efficiency and quality. As we look ahead to 2025, industry experts anticipate groundbreaking innovations that will redefine the standards of precision in this technology. According to Dr. Emily Chen, a leading authority on cutting technologies, “The future of water jet cutting accuracy lies in our ability to integrate advanced automation and real-time data analytics, which will not only enhance precision but also minimize waste.” Her insights highlight the significance of innovation in pushing the boundaries of what can be achieved with water jet cutting systems.

As we delve into the top 5 innovations set to revolutionize water jet cutting accuracy, it becomes evident that a blend of technological advancements and industry expertise will shape the future of manufacturing. These innovations promise to improve control systems, enhance material handling, and utilize next-generation nozzles, laying the groundwork for more consistent and high-quality cutting outcomes. The continual pursuit of precision in water jet cutting is not just a matter of competitive advantage; it is essential for achieving sustainability and efficiency in the manufacturing processes of tomorrow.

The journey toward mastering water jet cutting accuracy is an exciting one, and the upcoming innovations in 2025 are bound to create significant ripples throughout the manufacturing industry. With experts like Dr. Chen paving the way, the potential for advancements in this field seems limitless, inviting manufacturers to embrace new technologies and improve their operational standards.

Emerging Technologies Enhancing Water Jet Cutting Precision in Manufacturing

Water jet cutting has undergone significant advancements in precision manufacturing, driven by emerging technologies that are redefining the industry standards. The integration of closed-loop control systems, for instance, has enhanced accuracy by ensuring real-time adjustments during cutting operations. According to a report by MarketsandMarkets, the global water jet cutting market is expected to grow from $1.3 billion in 2020 to $2.1 billion by 2025, highlighting a rising demand for precise cutting technologies. This growth is largely attributed to innovations that allow manufacturers to achieve tolerances as tight as ±0.1 mm, ensuring high-quality results across various materials.

Moreover, advancements in software algorithms have played a crucial role in optimizing the cutting process. Techniques such as adaptive cutting strategies enable machines to analyze material properties and adjust nozzle speed and pressure accordingly, increasing both efficiency and accuracy. A study published by the International Journal of Advanced Manufacturing Technology indicated that optimized water jet cutting can enhance material usage by up to 20%, reducing waste and costs. With these technologies, manufacturers are not only improving their precision capabilities, but also enhancing sustainability in production processes, paving the way for a more efficient manufacturing landscape.

Advancements in Software Algorithms for Improved Cutting Accuracy

The advancements in software algorithms are pivotal in enhancing the accuracy of water jet cutting technology, a crucial factor in precision manufacturing. As industries strive for greater efficiency and superior product quality, integrating sophisticated algorithms can significantly reduce the margin of error during the cutting process. These algorithms analyze various parameters, such as pressure, speed, and material characteristics, allowing for real-time adjustments that lead to cleaner edges and precise cuts.

Moreover, the introduction of explainable AI techniques further enriches this domain, providing manufacturers with insights into decision-making processes. By understanding how algorithms optimize cutting parameters, operators can not only trust but also refine these automated systems. This shift towards data-driven precision aligns with broader trends in industrial automation, where machine vision and AI applications are redefining operational capabilities across sectors, ensuring that cutting-edge innovations remain at the forefront of manufacturing excellence.

Materials Science Innovations Driving Performance in Water Jet Systems

In the realm of precision manufacturing, innovations in materials science are significantly enhancing the performance of water jet cutting systems. Recent advancements have enabled the use of high-performance abrasives and cutting heads that can withstand greater pressures and temperatures, resulting in precision cuts with tolerances as tight as ±0.005 inches. According to a report from the Global Water Jet Cutting Machines Market, the demand for more sophisticated cutting techniques is projected to grow by 15% annually, driven primarily by industries such as aerospace and automotive, where accuracy is paramount.

Moreover, the integration of advanced materials in the construction of water jet systems is reshaping the landscape of modern manufacturing. Research indicates that next-generation water jet systems are increasingly incorporating composite materials and ceramics, which provide enhanced durability and reduce wear over time. This innovation not only boosts the reliability of cutting operations but also minimizes downtime for maintenance. As a result, manufacturers can achieve higher efficiencies, with some systems reporting up to a 30% increase in cutting speed without compromising on quality. The continuous evolution of materials science holds the key to unlocking even greater possibilities in water jet cutting technology.

Integration of AI and Machine Learning in Water Jet Cutting Processes

The integration of AI and machine learning into water jet cutting processes marks a transformative shift in precision manufacturing. As these technologies continue to evolve, operators are increasingly able to harness predictive analytics and real-time data processing to enhance cutting accuracy and efficiency. The application of machine learning algorithms allows for smarter calibration of water jet systems, optimizing pressure and flow rates in response to varying material properties. This intelligent approach not only reduces material waste but also improves the overall quality of the finished products.

Furthermore, the emphasis on technological adoption extends beyond just the machinery; it encompasses the workforce as well. To fully leverage these advancements, operators must invest in upskilling their personnel, enabling them to interact effectively with AI systems and optimize production processes. As the global CNC machine market experiences significant growth, driven by a compound annual growth rate of 5.5%, the symbiotic relationship between AI integration and advanced manufacturing practices will be essential for staying competitive in the industry. The next wave of water jet cutting innovations will undoubtedly hinge on the synergy between cutting-edge technology and skilled operators.

2025 Water Jet Cutting Accuracy Innovations

Future Trends: How Water Jet Cutting Will Revolutionize Precision Manufacturing

The future of precision manufacturing is being reshaped by innovations in water jet cutting technology. As industries increasingly prioritize accuracy and efficiency, the latest advancements in water jet cutting promise to enhance precision in ways previously unimaginable. With their capability to cut intricate designs in a variety of materials without altering their properties, water jets are set to redefine manufacturing standards. The increasing use of real-time data analytics and automation in these systems will further bolster their accuracy, ensuring that manufacturers can meet the rigorous demands of modern production.

Tip: To stay competitive, manufacturers should invest in training for their technical teams to fully leverage these new water jet technologies. Understanding the nuances of water jet systems can optimize cutting processes, reduce waste, and elevate product quality.

Moreover, sustainability is becoming a significant aspect of the manufacturing process. Water jet cutting uses fewer resources compared to traditional methods and generates less waste, making it an eco-friendly alternative. Innovations such as closed-loop water recycling systems are also on the rise. These advancements not only improve efficiency but also align with global green initiatives.

Tip: Consider integrating recycling systems into your water jet cutting operations. This approach not only minimizes environmental impact but can also lead to cost savings in the long run.

Related Posts

-

Unlocking Precision: How Water Jet Cutting Systems Revolutionize Metal Fabrication with 0.005-Inch Accuracy

-

Maximize Precision and Efficiency with Local Water Jet Cutting: The Future of Material Processing

-

The Future of Cutting Technologies Exploring the Benefits of Water Jet Abrasive Systems

-

Exploring the Benefits of Water Jet Cutting for Precision Stainless Steel Fabrication

-

The Ultimate Guide to Understanding How a Water Jet Head Transforms Industrial Cutting

-

Why Choosing the Right Dock Hoist is Essential for Your Marine Operations